NTC thermistors: Material properties and B value analysis

2024-04-28 10:54:27 60

NTC and thermistor

NTC (negative temperature coefficient) refers to thermistor phenomena and materials that have a negative temperature coefficient and a decreasing resistance index relationship as the temperature rises.

This kind of material is the use of manganese, copper, silicon, cobalt, iron, nickel, zinc and other two or more kinds of metal oxides are fully mixed, molding, sintering and other processes made of semiconductor ceramics, can be made with negative temperature semiconductor ceramics. Coefficient (NTC) of thermistor. Its resistivity and material vary with the proportion of material composition, sintering temperature, sintering temperature and structural state. Now there are also non-oxide NTC thermistor materials represented by silicon carbide, digital tin, silicon nitride, etc.

- In 1834, scientists first discovered that silver has a negative temperature coefficient.

- In 1930, scientists found that cuprous oxycuprous oxide also had a negative temperature coefficient, and it was successfully used in the temperature compensation circuit of aviation instruments. In addition, due to the continuous development of transistor technology, thermistor research has made significant progress.

- 1960 Certified NTC thermistor. NTC thermistor is widely used in temperature measurement, temperature control, temperature compensation and so on.

Thermistor can also be used as an electronic component such as instrument line temperature compensation and thermocouple cold end temperature compensation. Automatic gain control can be achieved by using the self-heating characteristics of NTC thermistor, and the resistance value of the RC oscillator stabilizer circuit is also related to the ambient temperature conditions when the self-heating temperature is much higher than the ambient temperature, so the thermistor is often used in the current meter, flow meter, gas analyzer, thermal conductivity analysis, and made of special detection elements.

Power type NTC thermistors are mostly used for power surge suppression. Surge suppression with NTC thermistor, is a high-power wafer thermistor, often used in capacitors, heaters and motor start electronic circuits in the circuit power interruption moment, the circuit will produce a surge current many times higher than normal operation, and the initial resistance of NTC thermistor increases, can inhibit excessive current in the circuit. Thereby protecting its power supply circuit and load. When the circuit enters the normal working state, the thermistor causes the temperature of the resistor to rise due to the current, and the resistance value drops to a small amount, which will not affect the normal operation of the circuit.

B-value characteristic

The B-value of the thermistor is one of the attributes of the NTC, and the B-value is simply the Material Coefficient.

Different B values in the same temperature range indicate that the material may not be the same, because the NTC thermistor is a negative temperature coefficient with a regular decline in resistance value as the temperature rises, the B value represents the curvature of the curve or the sensitivity index of the temperature, and the resistance value represents the B value when the unit temperature changes.

Generally speaking, when the temperature decreases, the resistance curve will change a little steeper or a little flat. Generally speaking, the steeper the B-value increases the curve, and the steeper the curve indicates that the change in resistance value increases, which is relatively steeper and more sensitive; The smaller the B value, the flatter the curve, and the flatter the curve indicates that the change in the resistance value becomes so large, and the temperature coefficient of the resistance value is relatively small.

Note: The B value is the partition/coefficient of the characteristic curve approximating the temperature resistance value of a thermistor in a certain temperature range calculated by the population.

Since the B value reflects the resistance change rule between two temperature points, it can be calculated using the following formula, in percentage per million % /°CIndicates the unit.

Unless otherwise noted, the B value is usually measured in the temperature range [25, 50], by T1 = 25℃ (298.15K)andT2 = 50℃ (323.15K) The zero power resistance value is calculated.

According to formula 1, if the B value is known, the resistance value corresponding to the target temperature can be obtained, as follows:

Temperature coefficient

The temperature coefficient of an NTC thermistor is defined as the relative change in the resistance value relative to the change in temperature. The simplest conversion formula for calculating the temperature coefficient of an NTC thermistor is as follows:

The final result ends up with a minus sign because it's a "negative temperature coefficient," or it's a "positive temperature coefficient."

Resistance characteristics table

The manufacturer will give the B value when providing the electrical characteristics of the thermistor, but it is not necessary to do not need the resistance characteristic table.

The use of B values allows all desired temperature resistance values to be derived, because B values describe the relationship between temperature and resistance within a certain temperature range, whereas thermistors represent a nonlinear relationship between temperature and resistance, unless this relationship cannot be accurately described by B values and formulas for all temperature ranges. Otherwise, once the thermistor of different manufacturers has the same B value, the formula is used to deduce that it is not the same resistance value.

An example of a temperature-resistance value characteristic

For example, the B value within [-25 ° C ~50 ° C] has been given, which means that there is no problem with the formula in the interval of 25~50 ° C, beyond this range, then the B value is different, so the resistance value obtained by the formula is not in this range.

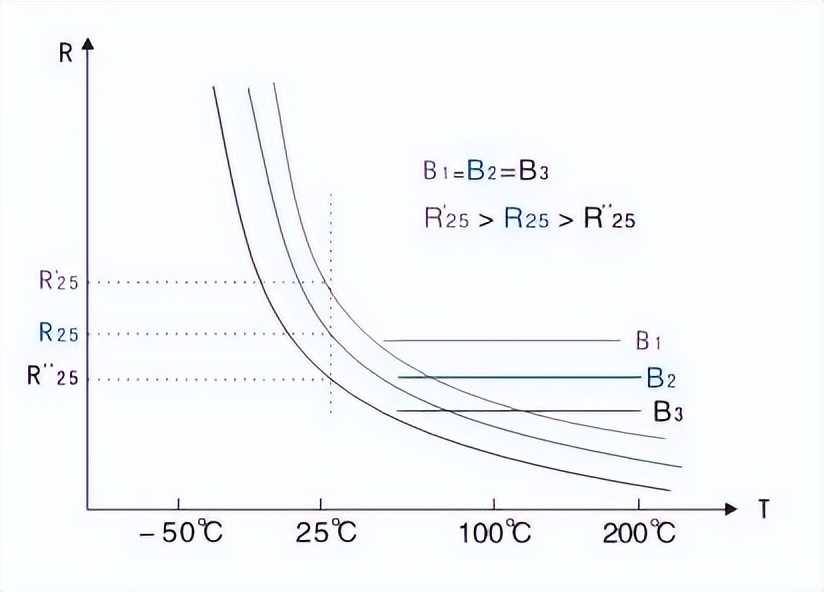

As shown below, there are three thermistors with the same B value, but their resistance values are different. It can be seen that the B value is only a certain range of parameters for each thermistor, it only reflects part of the characteristics of the thermistor, and is not a rigorous parameter, in practical applications, the need to provide resistance table within the detection temperature range is the correct approach.

The range of B value is generally 1800K ~ 5800k, and the temperature measurement point range is usually [25, 50], [25, 85], [0, 100] or [0, 50]. Some manufacturers can provide special NTC thermistor B value customization.

case

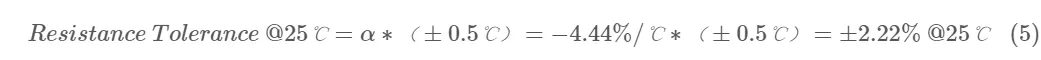

The customer ordered 10,000 W thermistors with an accuracy of ±0.5°C. The part number is MF52A-103, and B is equivalent to 3950 K.25°C (298.15 K).

According to Formula 3, the thermistor temperature coefficient α is obtained:

According to the thermistor temperature coefficient α and its device accuracy, the temperature tolerance at 25℃ can be obtained as follows:

Electrical characteristic

-

Resistance: R25 = 50kΩ ± 2%. That is, at 25, its resistance value is 50k ohms, and the resistance tolerance is 2%.

-

B Average value: B25/50 = 3950K ± 2%. That is, the material coefficient B value of the NTC thermistor has an average B value of 3950K between 25 and 50, allowing a difference of 2%.