How to effectively reduce the capacitor damage rate

2024-04-26 16:09:15 59

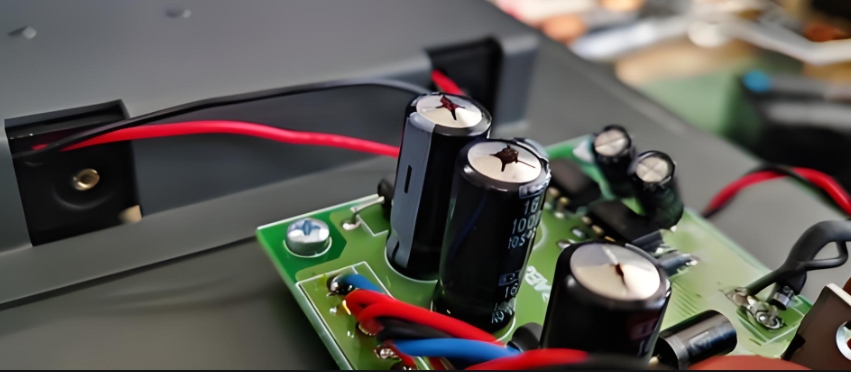

As one of the basic electronic components, the core function of capacitor is to store electric energy and release it in the form of electric field, which is widely used in various circuits such as filtering, coupling, resonance and energy storage. According to the different dielectric materials, structural design and application occasions, capacitors are mainly divided into the following categories:

-

Ceramic capacitor: ceramic material as the medium, with small size, good stability, high temperature resistance and other advantages, often used in high-frequency circuits and temperature sensitive occasions.

-

Aluminum electrolytic capacitor: Aluminum foil as the anode, electrolyte as the cathode, large capacity, low cost, suitable for power filter, low frequency coupling and other scenarios.

-

Film capacitor: including polyester film, polypropylene film and other types, low dielectric loss, good frequency characteristics, suitable for high frequency, high stability of the circuit.

-

Tantalum electrolytic capacitors: using tantalum metal oxide as the medium, small size, large capacity, high voltage resistance, long life, suitable for demanding military, aerospace and medical equipment.

Understanding the basic characteristics and application range of various capacitors is the basis for scientific selection, rational use and effective reduction of damage rate.

Summary of common damage causes of capacitors

Capacitor damage often stems from the following aspects:

Overvoltage: Reignition overvoltage. When the capacitor bank is cut off, the circuit breaker may reignite, resulting in a high reignition overvoltage, resulting in the breakdown of the capacitor electrode insulation. Transient high voltage: The capacitor may be hit by lightning, power system operation error, power surge and other transient high voltage impact, exceeding the rated voltage of the capacitor, causing breakdown.

Overcurrent: When the capacitor is connected to the power grid, the initial charging process may lead to a large instantaneous current (inrush current), which can overheat the capacitor if it is too large and lasts for a long time. Harmonic overcurrent: The harmonic existing in the power grid will cause the capacitor to withstand additional harmonic current, and too high harmonic current will accelerate the heat of the capacitor, resulting in insulation aging and damage.

Quality problems and aging: dielectric defects, capacitor internal dielectric may have defects, defects, conductive impurities or conductive particles, which can lead to breakdown short circuit. Electrical aging and thermal aging, long-term work at high temperature, high load conditions, dielectric materials may occur electrical aging or thermal aging, reducing insulation performance. Electrochemical reaction: An electrochemical reaction may occur inside the capacitor, resulting in deterioration of dielectric properties. Silver ion migration may occur in electrolytic capacitors, affecting the insulation between electrodes. Mechanical damage, mechanical stress during the manufacturing process or during use may cause dielectric damage. The molecular structure changes, and the molecular structure of the dielectric changes due to high temperature, chemical erosion and other factors, which affects the performance of the capacitor.

Electrical connection problems: open circuit, capacitor internal lead break, poor terminal contact or capacitor component damage, resulting in circuit disconnection. Short circuit, dielectric breakdown to form a penetrating defect, resulting in direct conduction of the two poles.

Environmental factors: High humidity, high humidity may lead to moisture inside the capacitor, increase leakage current, reduce insulation performance, and even cause arc between electrodes. Low pressure, in a low pressure environment, the internal pressure of the capacitor is reduced, which may affect the dielectric performance and increase the risk of breakdown. Mechanical stress, external mechanical stress may cause a transient short circuit in the dielectric.

Insufficient protection measures: lack of overvoltage protection, capacitor banks are not equipped with overvoltage protection devices (such as lightning arrester, overvoltage suppressor, series reactor, etc.), so that they have no protection against overvoltage events. The capacitor is not equipped with a single fuse, or the fuse characteristics are not good (such as ampere-second characteristics are not appropriate), and the faulty capacitor cannot be cut off in time.

Improper maintenance: Frequent operation, such as frequent switching of capacitor banks during agricultural irrigation seasons, accelerates insulation fatigue and damage. The capacitor itself is not grounded or poorly grounded, which may lead to static electricity accumulation, increased interference, or increased safety risks.

Improper design and selection: the capacitor type does not match the application conditions, and the selected capacitor type is not suitable for the specific working environment or load characteristics, such as insufficient temperature grade, insufficient voltage grade, and not suitable for harmonic environment. The configuration of the control protection device is unreasonable, the configuration of the control protection device is imperfect or the work is unreliable, and the status of the capacitor can not be effectively monitored and the faulty capacitor can be removed in time.

Through regular inspection, reasonable selection and maintenance of capacitors, strengthening protection measures and improving the operating environment, capacitor damage can be effectively prevented and its service life can be extended. When the capacitor is suspected of damage, you can measure the capacitance value, loss Angle tangent, insulation resistance and other electrical parameters, or observe the abnormal phenomenon of equipment operation (such as abnormal sound, heat, smoke, etc.) to determine whether there is a problem.

Capacitor selection and use precautions

In the process of capacitor selection and use, in order to ensure that it can work stably and efficiently in the circuit and avoid unnecessary damage, the following principles and precautions should be followed:

Selection notes:

-

Capacitor type selection: According to the circuit operating frequency, voltage level, temperature range, power loss, volume limit, cost and other factors, choose the appropriate capacitor type, such as film capacitor, electrolytic capacitor, ceramic capacitor, tantalum capacitor, etc.

-

Rated voltage: Ensure that the rated voltage of the selected capacitor is higher than the actual operating voltage, and it is usually recommended that the operating voltage does not exceed 80% of the rated voltage to ensure safety margin and long life.

-

Capacitance value: According to the circuit design requirements, the capacitance value is accurately selected, considering its impact on the circuit frequency response, filtering effect, energy storage requirements, oscillation frequency, time constant and other factors.

-

Temperature characteristics and operating temperature range: For temperature-sensitive applications, choose a capacitor with a small temperature coefficient and good stability; Ensure that the capacitor can work stably at the actual operating environment temperature, and does not exceed its rated maximum operating temperature.

-

Equivalent Series resistance (ESR) and equivalent Series inductance (ESL) : For circuits with high frequency, high speed or low loss requirements, choose capacitors with the lowest ESR and ESL possible to reduce power loss and signal distortion.

-

Ripple current resistance: For applications such as power supply filtering and inverter output filtering with large ripple currents, it is necessary to select capacitors that can withstand the corresponding ripple current.

-

Package form and size: Select the appropriate package form and size according to the board space, heat dissipation requirements, mechanical strength requirements, etc.

-

Reliability and life: For applications with long-term work and high reliability requirements, choose capacitors with long life and high reliability, such as long-life electrolytic capacitors, solid state capacitors, etc.

-

Certification and standards: Confirm that capacitors comply with relevant safety standards (such as UL, IEC, EN, etc.) and environmental requirements (such as RoHS, REACH, etc.), especially for products used in specific industries (such as medical, automotive, aerospace, etc.).

Precautions for use:

-

Correct polarity: For polar capacitors (such as electrolytic capacitors), ensure that the positive and negative terminals are correctly connected to prevent capacitor damage due to reverse connection.

-

Voltage limit: During use, the voltage at both ends of the capacitor is always monitored to ensure that it does not exceed its rated voltage to prevent overvoltage from causing breakdown or early failure.

-

Current limitation: To avoid long-term overload operation of capacitors, especially under high frequency, high current or pulse current conditions, attention should be paid to its rated current and instantaneous current bearing capacity.

-

Temperature monitoring: Monitor the operating temperature of the capacitor to ensure that it does not exceed the maximum operating temperature, too high temperature may lead to accelerated aging of the dielectric, performance decline or even failure.

-

Mechanical stress: Prevent capacitors from being subjected to mechanical vibration, shock or excessive installation stress, so as not to affect their electrical performance or cause mechanical damage.

-

Heat dissipation and cooling: For capacitors working in high-power or high-temperature environments, appropriate heat dissipation measures should be provided, such as heat sinks, fans, thermal grease, etc., to ensure that their operating temperature is within the allowable range.

-

Maintenance and replacement: Regularly check the appearance of capacitors for abnormal phenomena such as expansion, deformation, and liquid seepage, and regularly test the capacitance value, loss Angle tangent and other parameters. If any abnormality is found, it should be replaced in time.

-

Protection circuit: When necessary, the capacitor is configured with overvoltage protection, overcurrent protection, overheat protection and other protection circuits to prevent damage under abnormal conditions.

Capacitor maintenance strategy

-

Periodic inspection: Periodically measure the electrical parameters of the capacitors in key equipment (such as capacitance value, leakage current, ESR, etc.), find the deterioration trend in time, and replace them in advance.

-

Troubleshooting: Conduct detailed fault analysis for capacitor damage events, find out the root cause, revise maintenance procedures or improve design, and prevent similar problems from happening again.

-

Environmental control: Keep the temperature and humidity of the working environment within the appropriate range to avoid damage to capacitors caused by violent temperature fluctuations and excessive humidity.

-

Inventory management: rationally plan capacitor inventory to avoid performance degradation caused by long-term storage; For capacitors that have been opened, they should be used as soon as possible to avoid moisture.