What are pull-up resistors, pull-down resistors and the differences

2024-04-28 16:06:42 47

First, concept and function

Pull-up resistance

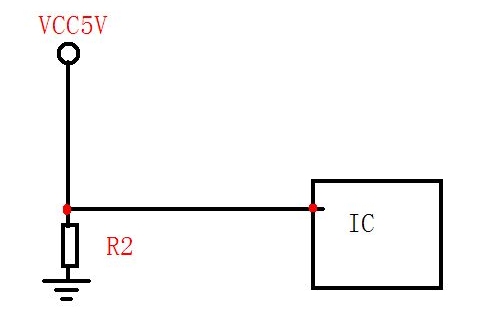

Concept: The pull-up resistor is usually connected between the input pin of the digital circuit and the positive terminal of the power supply, and its main function is to provide a determined high level (logic 1) to the input when the rest of the circuit is not driving that input. By pulling up the resistance, the uncertain behavior caused by the suspended input state can be avoided and the stability of the circuit can be enhanced.

Function: Pull-up resistors are usually connected between the signal line and the supply voltage (VCC or +V). When the output or input of the circuit is in a high resistance state (neither actively pulling up nor pulling down the signal), the pull-up resistor pulls the level of the signal line up to the supply voltage, thus ensuring that the signal is logically high (typically 5V or 3.3V). This is useful when you need to set the default high level state or enhance the drive capability of the circuit.

Pull-up resistance calculation formula

The formula for calculating pull-up resistance can vary according to different application scenarios, but the basic principle is to use Ohm's law to ensure that the circuit reaches the target voltage at the expected current. Here are some common methods of calculation:

Basic calculation formula

For simple pull-up or pull-down applications, the pull-up resistance can be calculated by the following formula:

Among them:

-

the power supply voltage.

-

the output voltage at low voltages (ideally close to 0V, but in practice there may be some voltage drop).

-

The the maximum current that can flow through the pull-up resistor at low output (also known as the filling current).

Consider the capacitive load of the I2C bus

On high-speed signal lines such as the I2C bus, in addition to considering voltage and current, it is also necessary to ensure that the signal can be stable within the specified time, so the choice of pull-up resistance also needs to consider the rise time. The calculation formulas may involve the capacitive load the rise time t_rtr, standard. An approximate calculation method is based on the formula given by the I2C bus specification:

Among them:

-

the maximum value of the pull-up resistance.

-

the rise time, which is determined according to the I2C bus speed (such as standard mode, fast mode, high-speed mode, etc.).

-

the total capacitive load of the bus, including line capacitance, contact capacitance, etc.

Practical application suggestion

In practical applications, the following points need to be considered when choosing a pull-up resistor:

-

Load capacity: Ensure that the pull-up resistor provides enough current to the circuit to maintain the signal level.

-

Rise/fall time: In high-speed signal transmission, the RC network of capacitors and resistors affects the steepness of the signal edge.

-

Power consumption: The voltage drop across the resistor multiplied by the current flowing through it equals the power consumption, which should be ensured to be within an acceptable range.

-

Signal integrity: While ensuring signal stability, minimize resistance values to reduce signal delay and reduce noise sensitivity.

Pull-down resistance

Concept: In contrast to the pull-up resistor, the pull-down resistor is connected between the input pin and the ground wire, and its role is to ensure that the input remains at a stable low level (logical 0) when there is no external signal to drive it. Pull-down resistors also help eliminate the dangling state, reducing the risk of circuit misoperation.

Function: The pull-down resistor is connected between the signal line and ground (GND). Its effect is the opposite of the pull-up resistance, when no other circuit is active to pull up the signal, the pull-down resistance will pull the electrical level of the signal line down to the ground level, ensuring that the signal is logically low (0V). This is helpful for scenarios where the default low level state needs to be set.

Second, the working principle

1. Voltage partial voltage and current path Whether it is pull-up or pull-down resistance, its working principle is based on the basic voltage partial voltage and Ohm's law. When the external signal is not connected or in a high resistance state, the circuit formed by the resistance and the input pin determines the level state of the pin. By selecting the appropriate resistance value, the desired voltage level can be achieved without consuming too much current.

2. Input impedance matching In circuit design, pull-up or pull-down resistors can also play the role of impedance matching to reduce the interaction between the signal source and the load, especially in high-frequency circuits, which helps to reduce signal reflection and distortion.

3. Design considerations

1. Selection of resistance value Choosing the right resistance value is the key. Excessive resistance will increase the rise/fall time of the input signal, affecting the speed; Too small will increase static current consumption. In general, the typical value of a pull-up or pull-down resistor ranges from 1kΩ to 100kΩ, depending on the requirements of the circuit and the maximum allowable current consumption.

2. Power consumption and temperature In high frequency or high current applications, special attention should be paid to the power consumption of pull-up/pull-down resistors to avoid overheating damage. The selection of low power resistance and reasonable layout of heat dissipation are important considerations in design.

3. Compatibility and stability The design also needs to consider compatibility with other circuit components to ensure that the pull-up/pull-down resistance will not interfere with other signal paths or introduce noise. In addition, appropriate decoupling and filtering measures can further enhance the stability and anti-interference ability of the circuit.

4. Application and case of pull-up resistance and pull-down resistance

Pull-up and pull-down resistors are very common in electronic circuit design, and they have a wide range of applications, the following are some typical application cases:

Pull-up resistor Application case:

1. Open Drain output circuit: When using devices such as MOSFET, OC (Open Collector) or OD (Open Drain) output, these devices can only pull down the signal line and cannot actively pull it up. For example, most devices in the I²C bus have an open drain output, which requires an external pull-up resistor to pull the signal line to a high level. In this way, when no device pulls down the signal line, the signal line defaults to a high state.

2. Key input processing: In the key circuit, in order to eliminate the uncertain state when the key is released (that is, eliminate jitter), it is usually connected to the input pin of the MCU at one end of the key and connected to the VCC through a pull-up resistor. When the key is not pressed, the input pin is kept high by a pull-up resistor. When the key is pressed, the pin is pulled down to GND, and the MCU detects this change to recognize the key event.

Pull-down resistor Application case:

1. Prevent the signal from floating: In some designs, in order to avoid the signal line being in an uncertain intermediate state when it is not driven, especially on the signal line with long distance transmission or high capacitance load, a pull-down resistor can be used. For example, a bus interface that is not connected to any device and is kept low by a pull-down resistor can effectively avoid misoperation due to static electricity or interference.

2. Three-state buffer control signal: When using a three-state buffer or similar device, the control signal is not driven, if you do not want it to be in an uncertain state, you can use a pull-down resistor to ensure that the signal is low. This way, the output of the buffer does not cause bus collisions when there is no enable signal.

3. Setting the initial state of the digital circuit: In complex digital logic circuits, some control signals need to have a certain low level state in the early start-up of the system. By pulling down resistors, you can ensure that these signals remain at the expected low level during the system initialization phase or before waiting for external signals.

Suppose you are designing a microcontroller-based system that includes a user control button and an LED indicator. The cathode (negative) of the LED is connected to GND, and the anode (positive) is connected to an output pin of the MCU via a current limiting resistor. In order to detect whether the button is pressed or not, one end of the button is connected to the input pin of the MCU, and the other end is grounded. However, to avoid the floating state when the button is released, the other side of the button is also connected to the VCC by a pull-up resistor. In this way, when the button is not pressed, the input pin of the MCU reads a high level, indicating that the button is not operated; When the button is pressed, the input pin is pulled down to GND, the MCU detects the low level and performs the corresponding logical action, such as lighting the LED.

Fifth, the role and difference of pull-up resistance and pull-down resistance

Pull-up resistance action: Ensure default high level: When the signal connected to the input pin is not driven by an external circuit, the pull-up resistance pulls the level of the signal line up to the supply voltage, providing a determined high level state. Enhanced drive capability: When used in conjunction with an open-drain output circuit, pull-up resistors provide the necessary current for a high level output, enhancing the drive capability of the signal. Improve signal quality: By providing a clear level, reduce signal noise and float, improve signal stability and reliability.

Pull-down resistance Action: Ensure default low level: When no external signal is driven, the pull-down resistance holds the signal line at a low level (ground potential), providing a determined low level state for the circuit. Suppression of interference: Placing a pull-down resistor at an inactive input prevents signal drift due to stray capacitors, etc. Simplify control logic: In some control circuits, pull-down resistors can help simplify logic design, such as maintaining a known initial state in a button or switch circuit.

Differential summary

-

Level direction: The most fundamental difference is that pull-up resistors are used to raise the signal to a high level, while pull-down resistors are used to lower the signal to a low level.

-

Application: Select pull-up or pull-down according to the specific needs of the circuit, for example, if you need to keep the level high when there is no input to activate a function, then use pull-up resistance; To ensure the default low level state, use a pull-down resistor.

-

Drive direction: The pull-up resistor is the injection current (filling current) to the device, while the pull-down resistor is the output current.