What are the causes of abnormal temperature rise of power capacitor

2024-04-29 14:40:15 144

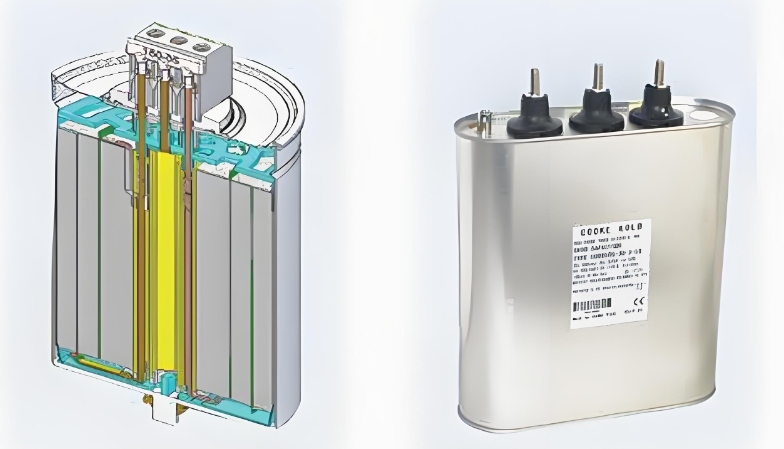

As an indispensable component in power system, power capacitor plays a vital role in improving power factor, improving voltage quality and reducing line loss. However, during long-term operation, capacitors may face various failures, among which abnormal temperature rise is a common problem that cannot be ignored. This is caused by its internal losses (such as dielectric losses and conductor losses). However, when the temperature rise exceeds the design allowable value, it is an abnormal phenomenon, which needs to be diagnosed and dealt with in time. Temperature rise not only affects the service life of capacitors, but also can be a precursor of system failure. Need timely diagnosis and treatment.

Causes of abnormal temperature rise of power capacitor

Material factor

1. Aging of medium materials

The core component of capacitor is dielectric, whose performance directly affects the working efficiency and life of capacitor. As time goes by, the dielectric material will gradually age, resulting in a decrease in dielectric constant and an increase in dielectric loss, resulting in an increase in temperature rise. Especially for capacitors that are used for a long time or operate in a high temperature environment, the problem of dielectric aging is more prominent.

2. Improper selection of conductor materials

The material and process of the conductors and connectors inside the capacitor are also key factors affecting the temperature rise. If you choose a material with low conductivity or large contact resistance, it will lead to an increase in heat when the current passes through, causing local overheating.

Design defect

1. The internal structure is unreasonable

Capacitors should be designed to ensure good heat dissipation performance, including the arrangement of capacitor units, the effectiveness of the cooling system, etc. Unreasonable design, such as the heat dissipation channel is not smooth, insufficient heat dissipation area, will limit the effective distribution of heat, resulting in abnormal temperature rise.

2. Insufficient overvoltage protection

Capacitors operating under overvoltage conditions not only increase energy loss, but also accelerate the aging of insulation materials, resulting in increased temperature rise. The lack of effective overvoltage protection measures is an important factor causing abnormal temperature rise.

Operating environment impact

1. High temperature environment

The operating temperature of a capacitor has a direct effect on its performance. The high temperature environment will accelerate the aging process of the internal materials, increase the loss of the medium, and reduce the heat dissipation efficiency, forming a vicious cycle, resulting in abnormal temperature rise.

2. Humidity and corrosion

The high humidity environment is easy to rust and corrodes the external and internal metal parts of the capacitor, increasing the contact resistance, and moisture may also penetrate into the dielectric, reducing the dielectric properties, resulting in a rise in temperature.

Maintenance mismanagement

1. Lack of regular testing

Without regular capacitor condition monitoring and maintenance, early temperature rise anomalies cannot be detected and solved in time, which may eventually lead to the sudden failure.

2. Improper operation and maintenance

Wrong operation methods, such as frequent switching, unreasonable load distribution, etc., will cause additional burden on the capacitor and increase the temperature rise. In addition, improper maintenance, such as improper cleaning, will also affect the heat dissipation effect.

Abnormal influence of temperature rise and examples

-

Accelerate the aging of the insulating medium: the inside of the capacitor usually uses paper, film or oil as the insulating medium. For example, the insulating oil in oil-immersed capacitors will oxidize and deteriorate at high temperatures, and its dielectric strength will decrease, resulting in the weakening of the insulation performance between capacitors. The typical manifestation of this aging is the phenomenon of partial discharge inside the capacitor, which will cause insulation breakdown in the long run. Example: A high voltage shunt capacitor that has been running in high temperature environment for a long time, after several years of operation, the insulation oil color becomes darker, and the water content and acid value in the oil are found to increase significantly, indicating that the insulation aging is serious.

-

Shorten the service life: In a wind farm, the capacitor bank originally designed for 20 years, after several consecutive years of hot summer weather operation, there are multiple sets of capacitor damage in less than 10 years, which needs to be replaced in advance, which directly shortens the actual service life of the equipment and increases the replacement cost.

-

Performance degradation: In power filtering applications, if the temperature rise of the filter capacitor is too high, the drift of its capacitance value may cause the filtering effect to be greatly reduced, and the harmonic content of the power grid will increase, affecting the normal operation of other electrical equipment. For example, if the temperature of the filter capacitor used in the UPS system of a data center is abnormal, the power supply quality may deteriorate and the stable running of the server may be affected.

-

Reduced stability: If the compensation capacitor in the power system is unstable due to abnormal temperature rise, it may cause voltage fluctuations and affect the stable operation of the system. A specific case is that during a summer peak load, due to the high temperature rise of the capacitor bank, the voltage fluctuation of the local power grid has affected the quality of residential electricity consumption.

-

Safety hazards: In a chemical plant, a high-voltage capacitor exploded due to overheating, not only damaged the surrounding electrical equipment, but also triggered a small fire, fortunately, it was put out in time and did not cause casualties. The direct cause of this accident is that the capacitor is overloaded for a long time, the temperature rise is too high, and eventually the insulation material fails.

-

Increased energy consumption: According to statistics, every 10°C increase in the temperature rise of the capacitor, its life is about halved, and the energy loss caused by heating will also increase. This means that in order to maintain the same level of power service, the system may need to consume more electricity to offset this loss. For example, a large substation successfully reduced the average operating temperature of capacitors by optimizing the capacitor configuration and strengthening the heat dissipation management, which in turn reduced the power loss by about 5%.

-

Rising maintenance costs: Frequent replacement of faulty capacitors requires not only direct equipment acquisition costs, but also indirect costs such as labor costs and downtime losses. For example, a power supply company found through analysis that due to the failure to effectively control the temperature rise of capacitors, the replacement cost of capacitors in its annual maintenance budget was 30% higher than expected, resulting in greater pressure on the company's operating costs.

Measures to avoid abnormal temperature rise of power capacitor

In order to effectively prevent and control abnormal temperature rise, it is recommended to take the following measures: First, be familiar with the permissible operating temperature range and rated voltage of the power capacitor to ensure that the capacitor works within the designed parameter range. Overtemperature or overvoltage operation is the main cause of abnormal capacitor temperature rise. Ensure that there is sufficient space around the capacitor installation location to facilitate air circulation and avoid obstructing heat dissipation due to dense installation. Keep the capacitor and the surrounding environment clean to prevent dust accumulation from affecting heat dissipation.

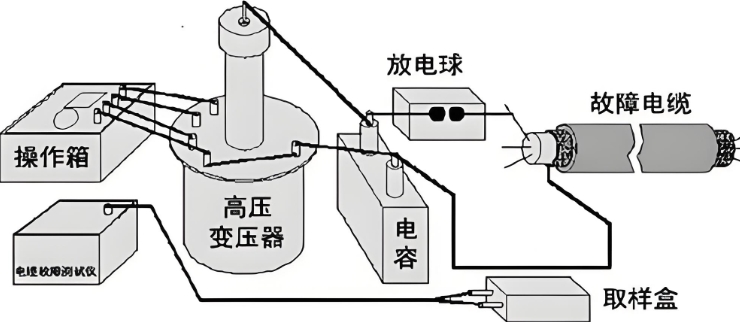

For capacitors with high power or continuous high load operation, heat sinks, cooling fans or other active cooling devices can be installed to enhance the heat dissipation effect, especially in the case of high ambient temperature or poor ventilation. Regular inspection of capacitors, including appearance check for expansion, oil leakage and other phenomena, as well as the use of infrared thermometer to monitor the capacitor surface and ambient temperature, timely detection and treatment of anomalies.

According to the actual reactive power requirements of the system, the capacitor capacity is reasonably configured to avoid long-term light load or overload operation and reduce unnecessary energy loss. Use appropriate overvoltage protection devices, such as lightning arresters, to limit the effects of transient overvoltage and long-term overvoltage on capacitors.

The capacitor temperature monitoring system is established, which uses intelligent sensors and data analysis technology to monitor the working status of the capacitor in real time, and automatically alarms and takes corresponding measures once the temperature exceeds the preset threshold. Conduct professional training for operation and maintenance personnel, so that they understand the working principle of capacitors, common faults and treatment methods, and improve the fault response speed and processing ability.