Common touch sensor switch failure causes and maintenance methods

2024-10-31 16:40:20 1050

catalogue

1. Introduction to the touch sensor switch

1.1 Main Types

1.2 Advantages and characteristics

2. Touch the structure of the sensor switch

3. Install the touch sensor switch

4. What if the touch sensor switch is not sensitive

5. Common causes of touch sensor switch failure

6. How to repair damaged touch sensor switch

Today we focus on touch sensor switches - an essential element of modern technology and everyday life. With its unique detection capabilities, touch sensor switches have become a key part of the bridge between people and machines, and are widely used in many fields from household appliances to industrial control systems. In the following time, we will explore the working principle of touch sensor switches, types, structures, installation points, and solutions when you encounter problems. Now, let's step into this world full of innovation.

1. Introduction to the touch sensor switch

Touch sensor switch is a device that triggers signals by detecting touch or proximity, which is widely used in modern technology and daily life. They can be used in a variety of devices, such as home appliances, consumer electronics, industrial control systems, and smart home devices. The main advantage of touch sensor switches is that they provide a more intuitive and convenient human-machine interface, while also improving the aesthetics and durability of the device.

Main type

Capacitive touch sensors: This type of sensor detects changes in capacitance to determine whether a touch has occurred. When a finger or conductive object is near or touches the sensor surface, the capacitance changes, triggering the signal. The advantages of capacitive touch sensors include high sensitivity, non-contact operation, and insensitivity to ambient light.

Figure: Capacitive touch sensor switch

Resistive touch sensors: These sensors detect changes in resistance to determine the position of the touch. When the touch screen is under pressure, the upper and lower two conductive layers contact to form a closed circuit, thereby changing the resistance value. Resistive touch sensors are generally less costly, but may not be as sensitive and durable as capacitive ones.

Advantages and characteristics

User-friendly: Provides intuitive operating experience, easy to understand and use.

Design flexibility: It can be designed in various shapes and sizes for different application scenarios.

Durability: No mechanical button wear problems, long life.

Aesthetics: It can be designed to be very simple and modern, enhancing the appearance appeal of the product.

2. Touch the internal structure of the sensor switch

Image: Internal structure of capacitive touch sensor (source: engineersgaraga)

The touch sensor switch usually includes a touch sensing area, which is the part of the user's direct interaction and is designed to be touched by a finger or other object; Capacitive touch sensors rely on changes in capacitance to detect touch events, while resistive touch sensors rely on changes in resistance; An integrated circuit (IC), which is responsible for monitoring changes in capacitance or resistance and converting these changes into digital signals; The signal processing and output module converts the detected information into the output signal in the form of high and low power equality; And a power management system that switches to a low-power mode to save energy when no touch event occurs. In addition, the touch sensor switch may also contain auxiliary components such as a protective housing, an indicator light, and a connection cable. Although the specific design may vary from model to model, these components are essential features of most touch sensor switches.

3. Install the touch sensor switch

When installing the touch sensor switch, it is necessary to consider the use environment of the sensor when determining the installation position. Avoid installing the sensor in damp, dusty, or vulnerable to electromagnetic interference. At the same time, ensure that the installation position is easy for users to operate without affecting its normal use.

Obtain required tools and materials, such as screwdrivers, electrical cables, insulation tapes, and drilling tools. Ensure that all tools and materials are complete and suitable for the sensor model used. Before installing the sensor, read the installation manual or manual carefully to understand the installation procedures and technical requirements. This helps avoid installation errors or missing important installation details.

Before installation, ensure that the power supply is cut off to avoid electric shock. This is essential to ensure security during installation. Connect the power and signal cables of the sensor correctly according to the instructions. Ensure that all wiring is secure and reliable to avoid short circuit or poor contact. Secure the sensor to its mounting position using appropriate fastening methods (such as screws, adhesives, etc.). Make sure the sensor is securely installed and will not move or fall off easily.

During the installation, keep the sensor surface clean to prevent dust or foreign matter from entering the sensor. After installation, wipe the sensor surface with a clean soft cloth. After installation, restore the power supply and test the function of the sensor. Make sure the sensor responds to touch properly and that the signal is transmitting properly. Considering that the sensor may be affected by environmental factors such as temperature and humidity, ensure that the installation position can meet the environmental adaptability requirements of the sensor.

After the installation is complete, make a reasonable maintenance plan, regularly check the working status of the sensor, clean the surface, and check whether the connection is loose.

4. What if the touch sensor switch is not sensitive

If the touch sensor switch becomes insensitive, the sensor surface should be cleaned to remove any dirt, grease, or other residue to ensure its surface is clean. Next, check the environmental conditions to ensure that the sensor is not affected by electromagnetic interference or electrostatic discharge and that the surrounding environment is suitable. If the sensor supports sensitivity adjustment, you can adjust the sensitivity setting appropriately. At the same time, check whether the connection between the sensor and the main control circuit is stable and reliable, and ensure that the power supply voltage is stable and meets the requirements of the sensor. If the sensor is controlled via a microcontroller, consider updating the firmware to improve touch response.

Image: Touch sensor switch insensitive detection measures (source: engineersgaraga)

If the above measures can not solve the problem, the sensor itself may be faulty or aging, then you can consider replacing the new touch sensor. Before attempting any adjustment or repair, be sure to disconnect the power supply and follow the recommendations in the instruction manual provided by the manufacturer to ensure safety and avoid further damage to the equipment.

5. Common causes of touch sensor switch failure

Understanding the common causes of touch sensor switch failure is helpful to take effective prevention and solution measures to ensure the normal operation of the device.

Surface contamination: If the surface of the touch sensor is covered with dust, grease, or other dirt, the sensor may not be able to correctly detect the touch action. Cleaning surfaces can solve these problems.

Environmental interference: Electromagnetic interference (EMI), electrostatic discharge (ESD), and other environmental factors (such as humidity, temperature changes) can affect the normal operation of the sensor. Reducing sources of interference or taking appropriate protective measures can help improve the situation.

Connection problems: Poor connection between the sensor and the control circuit, such as loose, disconnected or poor contact, can lead to failure. Check and tighten all connection points to ensure smooth signal transmission.

Improper sensitivity setting: If the sensitivity of the sensor is too high or too low, it may cause a false trigger or undetectable touch. Adjusting the sensitivity setting can improve this situation.

Power supply problem: Unstable or insufficient power supply voltage will affect the working state of the sensor. Check that the power supply is stable and that the voltage meets the requirements of the sensor.

Software failure: The software that controls the touch sensor may have errors or need to be updated. Firmware updates or software resets can sometimes solve problems at the software level.

Mechanical damage or aging: Prolonged use or accidental impact can cause mechanical damage or aging of the sensor, leading to performance degradation or even complete failure. In this case, replacing a new sensor is the most effective solution.

Design flaws: In some cases, design flaws in the sensor can also lead to failure. If a batch problem occurs, you may need to contact the manufacturer for a solution.

6. How to repair damaged touch sensor switch

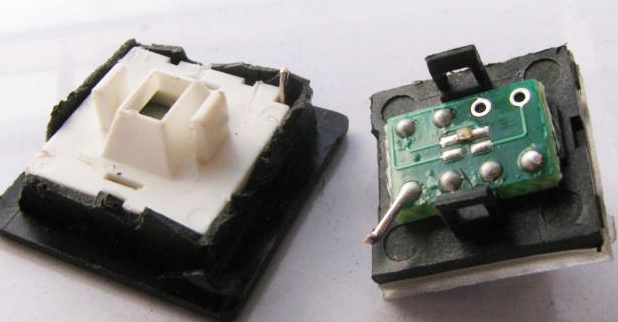

Picture: Damaged touch sensor switch

Before starting any repair of a damaged touch sensor switch, first make sure that the touch sensor switch has been disconnected from the power supply to avoid the risk of electric shock. Check the touch sensor and the cables to which it connects for obvious physical damage, such as breakage, loosening, or corrosion. Make sure all connections are secure and reliable. Use a clean lint-free cloth or cotton swab to gently wipe the sensor surface to remove dust, oil, or other contaminants. If necessary, a small amount of isopropyl alcohol (alcohol) can be used to clean. If the sensor supports sensitivity adjustment, check that the setting is appropriate. Sometimes performance can be improved by adjusting the sensitivity.

Further exclude the influence of environmental factors, such as electromagnetic interference (EMI) or electrostatic discharge (ESD). Try to test the sensor in a relatively clean and interference-free environment. If the sensor still does not work, you may need to open the housing to check the internal components. Look for obvious signs of damage, such as burned components, broken solder joints, or broken wiring.

For some simple problems, such as falling solder joints, you can re-weld. If a component is found to be damaged, such as a resistor, capacitor, or integrated circuit, you can try to replace it with a new component of the same specification. If the sensor is controlled by a microcontroller, you can check if there are firmware updates available. Updating firmware can sometimes solve problems at the software level. Some touch sensors may need to be recalibrated to work properly again. Follow the manufacturer's guidelines for calibration operations.

If none of the above steps resolve the problem, or if complex electronic repairs are involved, it is best to contact the manufacturer or a professional service provider for further diagnosis and repair.