Electronic component Light emitting Diode (LED) 2024 update

2024-08-29 16:38:24 1197

Light-emitting diodes (leds) are solid-state semiconductor devices that convert electrical energy into light energy. LEDs emit light of specific wavelengths when an electric current passes through them. I hope this blog will let you know more about light emitting diodes (leds).

Luminescence principle

How do leds convert electrical energy into light energy?

The basic structure of light emitting diode (LED) is PN junction. Its working principle is based on a phenomenon called "electroluminescence". When the forward bias voltage is applied to the P-N structure of the LED, electrons move from the N-type region to the P-type region, and holes move from the P-type region to the N-type region. When the electron and hole meet and recombine at the P-N junction, the electron transitions from a higher energy level to a lower energy level, and the released energy is emitted in the form of photons, forming visible light. The color of the light depends on the characteristics of the semiconductor material used, such as gallium arsenide (GaAs) for red leds and gallium nitride (GaN) for blue and green leds. Different semiconductor materials have different band structures and can emit different colors of light. In addition, the design of modern leds also considers how to effectively guide the photon emission and reduce heat loss, thereby improving the overall photoelectric conversion efficiency.

Performance parameter

What is the meaning of LED brightness, luminous intensity and other performance parameters?

Understanding LED performance parameters such as brightness and luminous intensity is very important for evaluating LED applications. Therefore, INFINITECH has compiled the following common parameter parsing to help readers who need it:

Brightness (luminous flux) : indicates the total light energy emitted by the LED per unit time, usually in lumens (lm) as a unit. The higher the brightness, the more light the LED emits.

Luminous intensity: refers to the luminous flux emitted by the LED in a unit solid Angle, usually in Candela (cd) as a unit. This is a measure of the brightness of the LED in a specific direction.

Spectral Power distribution (SPD) : describes the light output intensity of the LED at different wavelengths. It can help determine the color properties of the LED, such as color temperature.

Color temperature: Used to describe the color characteristics of the light emitted by the LED, usually expressed in Kelvin (K). Lower color temperatures (e.g. 2700K) show warm yellow, and higher color temperatures (e.g. 6500K) show cool white.

Color Rendering Index (CRI) : Measures the ability of an LED to reproduce the true color of an object. CRI values range from 0 to 100, with higher values indicating better color rendering.

Working current: The current required for the normal operation of the LED. The correct current setting is essential to ensure the life and efficiency of the LED.

Operating voltage (Vf) : The voltage required for the LED to start emitting light at a forward bias voltage. Different leds have different operating voltages.

Angle of view: refers to the Angle range in which the LED can still maintain a certain brightness level at different angles. The larger viewing Angle means that leds can provide uniform light over a wider range of angles.

Efficiency: Usually refers to the luminous efficiency, that is, the luminous flux produced per watt of input power, and the unit is lumens/watts (lm/W). The higher the efficiency, the more energy efficient the LED.

Life: The working life of the LED is usually expressed in hours, such as L70 life refers to the time point when the LED brightness decays to 70% of the initial brightness.

Color and material

What are the different colored leds made of?

Leds of different colors are usually made of different semiconductor materials, because different materials have different band structures and are able to emit different wavelengths (colors) of light. The following are several common colors of leds and their corresponding materials:

Red leds: Usually use gallium arsenide (GaAs) or aluminum gallium arsenide (AlGaAs). The wavelength is about 600 to 700 nanometers.

Orange light LED: usually use aluminum gallium indium phosphorus (AlGaInP). The wavelength is about 590 to 620 nanometers.

Yellow LED: usually use aluminum gallium indium phosphorus (AlGaInP). The wavelength is about 570 to 590 nanometers.

Green leds: Usually use aluminum gallium indium phosphorus (AlGaInP) or gallium nitride (GaN). The wavelength is about 500 to 570 nanometers.

Blue leds: Gallium nitride (GaN) is usually used. The wavelength is about 450 to 500 nanometers.

Purple leds: Gallium nitride (GaN) is usually used. The wavelength is about 380 to 450 nanometers.

White LED: It is usually achieved by coating a phosphor (such as Yttrium aluminum garnet YAG phosphor) on the blue LED chip. Blue light excites phosphor to emit yellow light, which is mixed with blue light to produce white light effect. There is no specific wavelength, but the result is a mixture of blue and yellow light.

The choice of these materials depends on the desired luminous wavelength. By adjusting the composition of the material, you can fine-tune the luminous color of the LED. In addition, there are some special leds, such as near-infrared and ultraviolet leds, which use different materials, but the basic principle is the same.

How to calculate the current limiting resistance

How to determine the correct current limiting resistance value to ensure the normal operation of the LED without damage?

In order to ensure that the LED works properly and is not damaged by overcurrent, a suitable current-limiting resistance value needs to be calculated. First, determine the supply voltage and the forward voltage (, the latter of which can usually be found in the LED's data table. At the same time, you also need to know the positive current (If the LED. Next, If. Then, select a standard resistance value that is closest to the calculated resistance value, and ensure that the maximum power consumption that the selected resistance can withstand is greater than or equal to the power consumed on the resistance when the LED is working, that is, Presistor Finally, check the temperature coefficient of the resistance to avoid changes in the resistance value due to temperature changes.

For example, if the supply voltage is 5 volts, the forward voltage of the LED is 3.2 volts, and the recommended forward current is 20 mA, the current limiting resistance value is (. This way, you can choose a resistor of about 90 ohms to limit the current and ensure that the LED is working properly.

Connection mode

Should leds be used in series or parallel?

The left picture shows the parallel circuit, and the right picture shows the series circuit

A series connection means that multiple leds are connected in turn, and current flows from one LED to the next, and so on. This connection is characterized by the fact that the current in all leds is the same, and the total voltage is the sum of the forward voltage of the individual leds. If one of the leds fails, the whole string of leds will stop working. A series mode is usually used when the supply voltage is higher than the forward voltage of a single LED in order to take advantage of the higher supply voltage.

Parallel connection refers to multiple leds connected side by side, each LED is directly connected to the power supply. This method is characterized by the same voltage at both ends of each LED. Even if one of the leds fails, the others will still work. Each LED needs to have its own current limiting resistance. It is usually used in parallel when the power supply voltage is close to the forward voltage of a single LED to increase brightness or improve the reliability of the system.

The combined use of series and parallel means that multiple leds are first connected in series to form a group, and then these groups are connected together in parallel. This combination combines the advantages of series and parallel connections to balance the demand for supply voltage and current while improving system reliability and flexibility. Suitable for situations where power supply voltage and current need to be balanced and fault tolerance of the system enhanced.

Selection suggestion

-

If the supply voltage is much higher than the forward voltage of a single LED, a series connection is usually selected.

-

If you need to limit the current of each LED, use a parallel connection and add a current-limiting resistor to each LED.

-

If reliability is important, you can choose a parallel connection, because even if one LED fails, the rest of the leds will still work.

Working condition

What is the best operating voltage and current of LED?

The forward voltage of an LED is usually between 1.8 and 3.6 volts, depending on the color and type of LED. For example, red and yellow leds have lower forward voltages (about 1.8 to 2.2 volts), while blue and white leds have higher forward voltages (about 3.0 to 3.6 volts).

Typical LED forward currents range from a few milliamps to hundreds of milliamps. Common low-power leds have a forward current of 20mA, while higher-power leds may require more current to achieve the desired brightness.

Current absorption, low output, LED light

Current source, output high, LED off

Give an example

Suppose you have a blue LED with a forward voltage of 3.2 volts and a recommended forward current of 20 mA. In this case, in order for the LED to work properly, you need to ensure that the voltage in the circuit is not less than 3.2 volts, and that the current passing through the LED is not more than 20 mA.

Test method

How to detect the quality of LED?

To detect the quality of LED, you can use a variety of simple methods. One of the most common is to use a multimeter for testing. First, set your digital multimeter to Diode test mode (usually labeled "diode") or a low resistance setting (like 200Ω or 2kΩ). Then, place the black probe (negative) of the multimeter on the cathode (short foot or side with a mark) of the LED, and the red probe (positive) on the anode (long foot). If the LED is good, the multimeter should show a forward voltage drop, which is usually between 1.8 and 3.6 volts, depending on the type of LED. Inversion of probe position (black probe in contact with the anode, the red probe contact cathode), the multimeter should show infinite or OL (scope), said reverse blocking feature is good.

Image from: Instant Encyclopedia

In addition to using a multimeter, you can also preliminarily judge the status of the LED through visual inspection. Check the LED for obvious physical damage, such as cracks, burn marks, or deformation. For the transparent or translucent package of LED, you can judge its quality by observing whether the interior is clean and whether there are impurities.

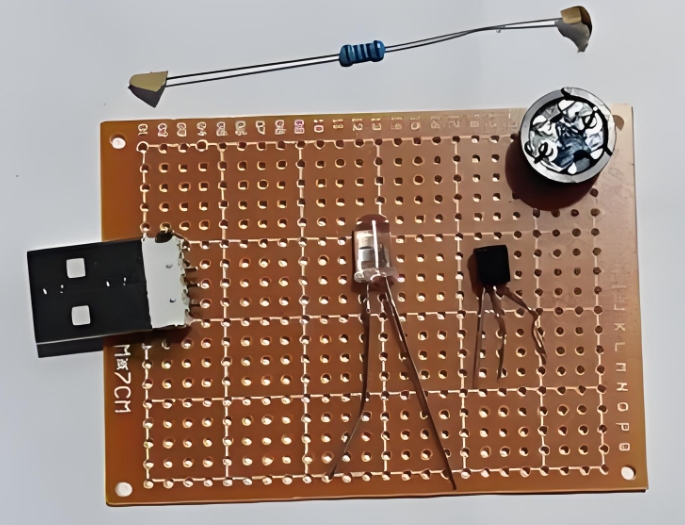

Another approach is to build a simple test circuit to detect leds. According to the power supply voltage and the forward voltage and current of the LED, the appropriate current limiting resistance value is calculated. Then use the appropriate power supply voltage to make sure it is higher than the forward voltage of the LED. Connect the LED to the circuit and observe whether it emits light. If it emits light, the LED is good; If it does not emit light, the LED may be damaged or there is a problem with the circuit.

When performing the above tests, care should be taken to ensure that the correct test voltage is used and that the rated voltage of the LED is not exceeded, so as not to damage the LED. Before using the multimeter, please make sure that familiar with the operation method, and take appropriate safety measures. Through these methods, you can more accurately detect whether the LED is intact. I hope you find this information helpful! If you have any questions or need further assistance, please feel free to ask questions.

Common faults and solutions

What is the reason why the LED is not bright?

Power problem

Undervoltage: The power supply voltage is lower than the forward voltage of the LED.

Power failure: The power supply does not provide enough current or does not work at all.

Solution: Confirm whether the power supply voltage meets the requirements of the LED and whether the power supply works normally.

Circuit connection problem

Wiring error: the positive and negative poles of the LED are reversed.

Open circuit: A part of the circuit that is disconnected, such as a broken line or poor contact.

Short circuit: There is a short circuit in the circuit, causing the current to bypass the LED.

Solution: Make sure the LED is installed correctly and there are no wiring errors or disconnections.

Current limiting resistance problem

Inappropriate resistance value: The current limiting resistance value is too high or too low, resulting in insufficient current to light the LED or overcurrent damage the LED.

Resistance fault: The current limiting resistance is damaged or disconnected.

Solution: Use a multimeter to check whether the resistance value of the current-limiting resistor is correct and whether the resistor is damaged.

LED itself problems and other factors

Physical damage: LED internal damage, such as solder joint fracture, chip failure, etc.

Electrical failure: The electrical characteristics of the LED have changed and cannot work properly.

Aging: The LED is used for too long, and the brightness gradually decreases until it is not bright.

High temperature: The LED works at too high a temperature, which may cause damage to the internal components.

Excessive humidity: Excessive humidity may lead to internal corrosion or short circuit of the LED.

Driver circuit problem: There is a problem with the driver circuit, which cannot provide a stable current or voltage.

Solution: Use a multimeter to test the forward voltage of the LED, or test the LED in another circuit that is known to be normal. If a component is found to be faulty, try replacing it with a new one.

What are the causes of high-power LED burning and preventive measures?

High power LED burn reasons

Overheating: LED will produce a lot of heat when working, if the heat dissipation is not good, it will lead to high temperature. The use of high-power leds in high temperature environments can also lead to overheating.

Overcurrent: The current limiting resistor or drive circuit is improperly configured, resulting in too much current passing through the LED. The power supply voltage is unstable, resulting in excessive instantaneous current.

Electrical failure: A short circuit in the circuit causes an abnormal current. The power supply voltage is higher than the rated voltage of the LED.

Mechanical damage: The LED is damaged internally by physical impact or vibration.

Quality problems: quality problems exist in the LED manufacturing process.

preventive measure

Improved heat dissipation: The LED is equipped with an efficient radiator to ensure that heat can be effectively dissipated. Reasonable arrangement of LED installation position, avoid too dense.

Precise current limiting: A constant current drive circuit is used to ensure that the LED operates within a safe current range. According to the rated current and power supply voltage of the LED, calculate and use the appropriate current limiting resistance.

Protection circuit: Install overvoltage protection devices, such as voltage regulator diodes, to prevent LED damage caused by high voltage. Use a fuse or other protection to prevent short circuits.

Quality control: Purchase products from reputable manufacturers and ensure that the products have undergone rigorous quality inspection. Check the LED and its circuit regularly and replace the damaged parts in time.

Environmental control: Ensure that the LED works in the appropriate temperature and humidity environment.

By taking the above preventive measures, the risk of high-power LED burning can be greatly reduced to ensure the long-term stable operation of LED.