Detailed guide: How to test electronic components on a circuit board

2024-08-27 15:20:59 945

Circuit board (PCB) has become an integral part of modern electronic products. Ensuring that every electronic component on the circuit board is working properly is critical to the reliability of the product. Here, INFINITECH will detail methods and techniques for testing electronic components on circuit boards to help users with the same testing needs.

First, the importance of testing

Effective testing in the manufacturing process can significantly reduce failure rates, reduce rework costs, and increase customer satisfaction. By detecting problems early, manufacturers can take quick steps to fix them, avoiding more expensive repairs later on. It can also ensure that each component works as designed, thus ensuring that the board functions as expected and improving the overall reliability and durability of the product. By early detection of potential failure points, maintenance costs and customer complaints after the product is put into use can be effectively reduced, while enhancing product quality and consistency. Especially for safety-critical applications such as medical devices and automotive electronics, testing also ensures that there are no safety incidents caused by component failure, thus meeting the safety and performance standards required by industry standards and regulations.

Second, what basic tools can be used for testing

Digital multimeter (DMM) : Measures basic electrical parameters such as voltage, current, and resistance. Test element: It can be used to test the basic state of resistors, capacitors, diodes, transistors, etc.

Oscilloscope: Observe the waveform of voltage change over time to help diagnose signal distortion and other problems. Test components: suitable for testing signal waveforms in signal generators, amplifiers, oscillators and other circuits.

Logic analyzer: Capture the timing information of digital signals, used to analyze the operation of digital circuits. Test element: suitable for testing digital signal sequences of microprocessors, microcontrollers, digital ics, etc.

Signal generator: Produces a signal of known frequency and amplitude for testing the response of a circuit. Test element: Used with oscilloscope to test the frequency response of amplifier, filter and other circuits.

Power supply: Provides a steady DC voltage or current to power a test circuit. Test element: Suitable for all circuits that require external power supply.

Characteristic curve tracker: Test the characteristic curve of semiconductor devices such as transistors. Test element: Used to test the I-V characteristics of transistors, Fets, etc.

Boundary scan test tools (such as the JTAG tester) : Non-invasive testing of components already installed on the board using boundary scan technology. Test components: Suitable for testing integrated circuits, connectors, etc.

Automated Test Equipment (ATE) : Automates the function and performance of complex circuit boards. Test components: Suitable for batch testing of many components on complex circuit boards.

These tools can be selected and combined according to the specific needs of the test. For example, for simple resistance and capacitance tests, a digital multimeter is sufficient; For complex digital or analog circuits, advanced test equipment such as oscilloscopes, logic analyzers, and signal generators may be required.

What do I need to do to prepare for the test?

Ensure that the power supply is disconnected to avoid the risk of electric shock.

Check whether the test equipment, such as the multimeter, is in good condition.

Familiar with circuit schematics, understand the position and function of each component.

Check whether the type and specification of the components meet the design requirements.

Prepare the necessary test tools, such as digital multimeter, oscilloscope, signal generator, etc.

Ensure that all tools are calibrated and within expiry date.

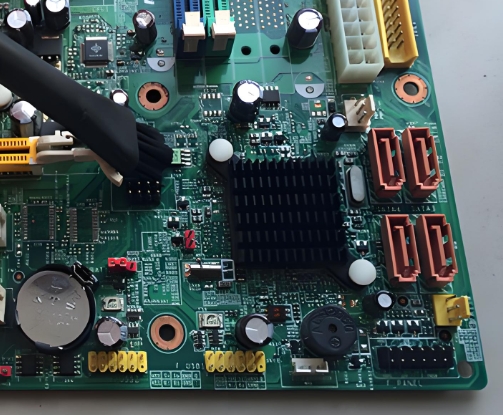

Observe whether the PCB has obvious physical damage, such as cracks, burn marks, etc.

Clean the PCB surface to remove dirt or residue that may affect test results.

If possible, isolate the problem area from the entire circuit before testing.

Record the environmental conditions (such as temperature, humidity) at the time of the test, as well as the test equipment used and the setting parameters.

Develop a clear test process to determine the specific components to be tested and in what order.

Decide which test method to use (online or offline).

Have some spare components on hand so that they can be replaced quickly if a faulty component is found.

How to test different types of components and their precautions?

1. Resistance

Use the ohms of a digital multimeter (DMM) to measure resistance values. Place the marker on both ends of the resistor, read the displayed resistance value and compare it with the nominal value. If the resistance is installed in the circuit, the ohm file of the multimeter can be used for online testing, but it should be noted that the power supply needs to be disconnected at this time and ensure that no other components in the circuit affect the measurement result.

-

Note: Before testing, ensure that the resistance is not connected to the circuit to avoid other components affecting the measurement results. When using a multimeter, a range close to the resistance value to be measured should be selected to obtain a more accurate reading.

2. Capacitance

Most digital multimeters have the capability to measure capacitance by removing it from the circuit. For polar capacitors such as electrolytic capacitors, a simple charge and discharge loop can be used to check whether they can store and release charge correctly.

-

Note: Before testing, ensure that the capacitor is fully discharged to prevent the residual charge from causing injury to the tester or equipment. Pay special attention to polarity when testing electrolytic capacitors to ensure that the positive and negative electrodes are correctly connected.

3. Transistors

For bipolar transistors (BJTS), the diode test file of the multimeter can be used to check the forward voltage drop of the emitter junction and the collector junction; For field-effect tubes (FETs), you need to check the resistance between the gate and the source. Characteristic curve tracker is a special instrument used to test the characteristics of transistors, which can provide more detailed current and voltage characteristic curves.

-

Note: When testing transistors, pay attention to anti-static measures, such as wearing an anti-static bracelet. Ensure that the base, emitter, and collector of the transistor (for NPN or PNP transistors), or the source, drain, and gate (for MOSFETs) are correctly identified. When using a multimeter, select a mode suitable for transistor testing, such as diode test mode.

4. Integrated circuits

Use a dedicated integrated circuit tester or programmer to simulate the operating conditions of the IC and check that the output signal is as expected. For integrated circuits that are already mounted on the board, boundary scan test techniques such as JTAG can be used to check their functionality.

-

Note: When testing integrated circuits, it is usually necessary to provide the appropriate supply voltage and current. Depending on the function of the integrated circuit, it may be necessary to provide specific input signals. Make sure the pins are connected correctly to avoid short circuits or other damage. During the test, the influence of the ambient temperature is considered. Too high a temperature may affect the test result.

Other test tools

The oscilloscope can be used to observe the waveform of the signal, which is suitable for testing the integrated circuit of signal processing.

Logic analyzers are used to test digital circuits, such as microcontrollers, memory chips, etc., which can capture and display complex sequences of digital signals.

General considerations

Safety procedures are always followed to ensure that no harm is caused to personnel or equipment during testing.

Record test results for subsequent analysis and comparison.

Ensure a stable test environment and avoid external interference.

Calibrate test instruments regularly to ensure measurement accuracy.

When connecting or disconnecting the test instrument, ensure that the power supply is turned off to avoid damage caused by hot swap.

Fourth, how to choose the appropriate test method for different components?

a. How to choose the right test method?

Determine test objectives

-

Verify that components work as designed.

-

Evaluate component performance indicators, such as accuracy, stability, etc.

-

Locate the faulty component on the circuit board.

-

Ensure the quality of components in the production process is up to standard.

Understand component types

-

Resistance: Use the ohm file of a multimeter to measure.

-

Capacitance: Use a multimeter's capacitance file or a specialized capacitance tester.

-

Transistor: Diode test file or characteristic curve tracker using a multimeter.

-

Integrated circuits: Test using a functional tester or programmer, or using boundary scan technology (such as JTAG).

Choose the right test tool

-

Manual test: Use manual tools such as multimeters and oscilloscopes.

-

Automated testing: Use automated test equipment (ATE), boundary scan test tools, etc.

Consider the test environment

-

The laboratory environment allows for precise testing using high-end test equipment.

-

Production line environments may require fast and cost-effective testing methods.

-

Field service environments require portable test tools.

Consider cost and efficiency

-

Choose a cost-effective test method.

-

For high-volume testing, prioritize automated testing to increase efficiency.

Special consideration

-

For components that need to operate in extreme temperature (high/low temperature) conditions, special tests should be carried out using a temperature chamber.

-

To ensure that components and circuit boards are not affected by electromagnetic interference, EMC test equipment can be used.

Follow standards and specifications

-

Ensure that test methods comply with relevant industry standards and regulations.

-

Follow safety test procedures to protect testers and equipment.

Test flow planning

-

Pre-test checks that the circuit board and components are in good condition.

-

Execute the selected test program.

-

Record test results, analyze test data, adjust or re-test if necessary.

b. What are the advantages and disadvantages of manual testing versus automated testing?

Manual test

The advantage of manual testing is that it allows the tester the flexibility to adjust the testing strategy according to the specific situation. The testing process is intuitive and easy to understand and explain. Suitable for small batch testing or situations requiring subjective judgment. No need for expensive automated test equipment. Disadvantages: Manual testing is slow, especially for a large number of repetitive tasks. Manual operation can introduce errors or omissions. Different testers may have different test methods and results. Prolonged continuous testing is not possible.

Automatic test

The advantage of automatic testing is that it can quickly complete a large number of test tasks. The results of each test are more consistent, reducing the influence of human factors. Automated tools can provide more accurate test results. The same test steps can be easily repeated. Reduce the need for manual operation and reduce labor costs. It can be integrated with the software development process to support continuous integration/continuous deployment (CI/CD). Disadvantages: High cost of automated test equipment and software. Test procedures need to be maintained and updated regularly. Setting up and configuring an automated test system can be complex. For some testing tasks that require subjective judgment, automated testing may not be flexible enough.

Comparison of two test methods

Manual testing is more suitable for situations where human judgment is required, especially in small-scale tests. Automated testing is better suited for large-scale, repetitive testing tasks, especially in production environments. In practical applications, manual testing and automatic testing are usually combined to achieve the best test results. For example, automated tests can be used to handle routine, repetitive testing tasks, while manual tests can be used to handle those tasks that require human intuition and creative thinking.

Five, how to avoid damage to the circuit board or other components?

To avoid damaging the circuit board or other components during testing, take the following precautions: Ensure that the circuit board is not connected to a power source before making any physical contact or measurement. After power failure, wait for a period of time for the capacitor to discharge, so as to avoid accidental damage caused by residual charge. Use an anti-static wristband or stand on an anti-static mat to reduce the risk of electrostatic discharge. Avoid touching sensitive components, especially integrated circuits and transistors. Use the right test tools and probes. Ensure that the test tool is calibrated and used correctly according to the manufacturer's guidelines. Follow the correct test procedure and do not exceed the maximum rating of the test instrument.

Handle boards and components gently to avoid physical damage caused by excessive force. Use appropriate tools, such as test probes with non-metallic tips, to prevent scratching or short circuits. For particularly sensitive parts, consider using a quarantine or cover up to avoid accidental touch. If you need to test a particular component, consider temporarily disconnecting it from the rest.

Before the power-on test, check that the power supply voltage is correct and gradually increase the voltage until the operating voltage is reached. Monitor current consumption to ensure it does not exceed component rating. Pay attention to the temperature changes of the components to avoid overheating caused by prolonged power. Use temperature sensors to monitor the temperature of critical components, especially when carrying out load tests. Overvoltage protection, overcurrent protection and other safety measures are added to the circuit. Protect power lines with fuses or circuit breakers.

Record the circuit status and Settings before and after the test for easy tracking and comparison. Mark the parts that have been tested to avoid duplicate testing. Regularly check the integrity of the test equipment, including wires, probes, etc. Regular calibration according to manufacturer's recommendations. Read and follow the technical manuals and safety guidelines provided by board and component manufacturers.

Six, how to identify and locate the fault components on the circuit board?

Identifying and locating faulty components on a circuit board usually involves following a systematic set of steps. Here is the detailed process:

-

Preparation stage: Ensure that the circuit board is not connected to a power source to avoid the risk of electric shock. View circuit schematics and PCB layout drawings to understand the design of the circuit board. Prepare digital multimeter, oscilloscope, signal generator and other test equipment.

-

Initial inspection: Check whether the circuit board has obvious physical damage, such as cracks, burn marks, corrosion, etc. If necessary, gently clean the board surface to remove dirt or residue that could affect the test results.

-

Static test: Use the ohm level of the multimeter to measure the resistance value of each component and check whether it is in line with the nominal value. Test the connection points on the circuit board to ensure that they are connected and there is no disconnect. Suspected problematic components can be tested individually by disconnecting them to confirm whether they are faulty.

-

Dynamic test: After confirming the safety of the circuit board, connect the power supply and start the circuit board. Use a multimeter to measure the voltage of key nodes and ensure that the power supply voltage is normal and stable. Use an oscilloscope to observe the waveform of key signal points and check whether the waveform meets expectations. Test the functions of the circuit board, such as input/output response, signal transmission, etc.

-

Fault location: Compare the test results with the nominal values or expected behavior on the circuit diagram to look for deviations. Test components and connection points one by one, from power supply to load, by signal path. For suspected faulty components, replace them with new components of the same model to see if they return to normal. For some components, such as transistors, integrated circuits, etc., it can be slightly heated to detect whether there is a fault.

-

Analysis and maintenance: Record the data of each test point, including voltage, current, waveform, etc. Replace the faulty component. After replacing the component, repeat the previous test steps to confirm that the fault has been resolved.

-

Performance evaluation: Ensure that all functions of the board are working properly. Test whether the circuit board meets the design specifications and performance specifications.

-

Make maintenance records: record the data during the test, the problems found, and the actions taken. Update maintenance documentation, including a list of replacement components and test results.

What steps should be taken when encountering different types of failures?

Open circuit

-

Fault description: There is no conductive path somewhere in the circuit, resulting in the current cannot flow.

-

Diagnostic procedure: Use the continuity test function of the multimeter to check the location of the suspected break. If possible, try to disconnect the components associated with that area and test that part of the circuit separately. Check whether connectors, joints, and solder joints are loose or broken.

-

Solution: Reweld the broken solder joint. Replace damaged connectors or fittings. If a wire or trace is broken, try rewiring or connecting with a jumper.

short-circuit

-

Fault description: A conductive path appears between two points in the circuit that should not be connected.

-

Diagnostic procedure: Use the resistance test function of the multimeter to check the suspected short-circuit location. Disconnect the power supply and use a low voltage source (such as a battery) for a short circuit test. Check the solder joints and component pins on the circuit board for abnormal contact.

-

Solution: Remove short circuit caused by solder bridging or foreign matter. Reweld or replace damaged components. Repair or replace damaged circuit boards.

Component failure

-

Fault description: A single component or a group of components does not work properly.

-

Diagnostic procedure: Use a multimeter to measure the voltage and current at both ends of the component. Use an oscilloscope to observe the input and output signals of the components. Replacement method: Replace suspected faulty components with new components of the same model and observe whether they return to normal.

-

Solution: Replace the faulty component. Check for other points of failure around the component, such as short circuits or open circuits. Depending on the type of component, the circuit configuration or parameters may need to be adjusted.

Power problem

-

Description: The power supply voltage is unstable or incorrect.

-

Diagnostic procedure: Measure the output voltage of the power supply and check whether it meets the requirements. Check whether the power filter capacitor is normal. Use an oscilloscope to check for power ripple.

-

Solution: Replace the faulty power module. Install or replace the filter capacitor. Check the power cables and connectors to ensure reliable connections.

Signal quality problem

-

Fault description: Signal distortion, noise, or signal loss.

-

Diagnostic steps: Use an oscilloscope to observe the signal waveform. Check components along the signal path, such as amplifiers, filters, etc. Check that the grounding loop is complete and that the signal is properly grounded.

-

Solution: Replace the faulty signal processing element. Improve the wiring of signal lines to reduce interference. Adjust amplifier gain or filter parameters.

Thermal stability problem

-

Fault description: Component overheating causes performance degradation or failure.

-

Diagnostic steps: Use an infrared thermal imager to check the heating element. Check whether heat dissipation devices such as heat sinks and fans work properly. Check that the maximum power limit of the component is not exceeded.

-

Solution: Add heat sink or fan. Replace components with better heat dissipation performance. Optimize circuit design to reduce power consumption.

Mechanical failure

-

Description: The circuit board or component is damaged due to physical damage.

-

Diagnostic steps: Visually inspect the board for obvious physical damage. Check components for looseness or breakage.

-

Solution: Repair or replace the damaged circuit board. Reinstall or replace loose or damaged components

What are the steps of the complete test process?

Safety preparation

-

Make sure the board is not connected to a power source to prevent the risk of electric shock.

-

Wear appropriate personal protective equipment, such as insulated gloves.

Physical inspection

-

Check the circuit board for visible damage, such as cracks, burning, poor solder joints, etc.

-

If necessary, gently clean the board surface to remove dust or foreign objects.

Test preparation

-

Understand the circuit board design drawings and schematics, clear the function and position of each component.

-

Prepare the necessary test equipment, such as digital multimeters, oscilloscopes, logic analyzers, etc., and confirm their calibration status.

-

Develop test procedures and standards according to the function and structure of the circuit board.

Functional testing

-

Static test: Use a multimeter to perform a resistance test to check whether the resistance value of the component is normal when it is not powered on. Check the connectivity between nodes on the circuit board.

-

Dynamic test. After power on, use a multimeter to measure voltage and current to ensure that the power supply voltage is correct and stable. Use an oscilloscope to observe whether the waveform of key signal points meets expectations. Test the functions of the circuit board, such as input and output response, signal transmission, etc.

Isolation problem

-

Based on the test results, try to locate possible faulty components or problem areas.

-

Individual testing of suspected faulty components, such as validation using replacement methods.

Repair and replacement

-

The detected faulty components are replaced with new qualified components.

-

After replacing the component, repeat the above test steps to ensure that the problem is resolved.

Performance evaluation

-

Ensure that all functions of the board are functioning properly.

-

Test whether the circuit board meets the design specifications and performance specifications.

Document record

-

Document data during testing, problems found, and actions taken.

-

Update maintenance documentation, including a list of replacement components and test results.

Final inspection

-

Make sure there are no missing loose parts or foreign objects.

-

Perform final functional tests to confirm that the board is fully compliant.

The above is a relatively complete test process, following this process, you can effectively diagnose and repair the problem on the circuit board to ensure its normal operation. Testing the electronic components on the circuit board is a key step in ensuring product quality. By adopting proper testing methods and technologies, manufacturers can increase production efficiency, reduce costs, and ultimately deliver more reliable products to consumers.