2024 Latest! Regulated power supply, switching power supply, DC-DC converter, charging circuit and constant current source circuit diagram

2024-07-11 14:21:03 1405

Circuit diagram is one of the basic skills that electronic engineers must learn, this INFINITECH collection of regulated power supply, DC-DC conversion power supply, switching power supply, charging circuit, constant current source related classic circuit information, to provide engineers with the most fresh circuit diagram reference materials, super detailed!

First, regulated power supply

3-25V adjustable voltage regulating circuit diagram

The voltage regulator can be adjusted in the range of 3.5V ~ 25V, the output current is large, and the adjustable voltage regulator tube circuit is adopted, so as to obtain a satisfactory and stable output voltage.

Working principle: After the rectifier filter, the DC voltage is provided by R1 to the base of the adjustment tube, so that the adjustment tube is on, and the voltage passes through RP and R2 to make V2 on when V1 is on, and then V3 is also on, and the emitter and collector voltage of V1, V2 and V3 no longer changes (its role is completely the same as that of the regulator tube). Adjust RP, can get a stable output voltage, R1, RP, R2 and R3 ratio determines the circuit output voltage value.

Component selection: Transformer T uses 80W ~ 100W, input AC220V, output double winding AC28V. Select 1A for FU1 and 3A ~ 5A for FU2. Use 6A02 for VD1 and VD2. RP uses about 1W ordinary potentiometer, resistance value is 250K ~ 330K, C1 uses 3300µF / 35V electrolytic capacitor, C2, C3 uses 0.1µF monostone capacitor, C4 uses 470µF / 35V electrolytic capacitor. R1 uses 180 ~ 220Ω/0.1W ~ 1W, R2, R4, R5 uses 10KΩ, 1/8W. V1 uses 2N3055, V2 uses 3DG180 or 2SC3953, V3 uses 3CG12 or 3CG80.

10A3 ~ 15V regulated power supply circuit diagram

10A3 ~ 15V regulated power supply circuit diagram

No matter the maintenance of computers or electronic production can not be separated from the regulated power supply, the following introduces a DC voltage from 3V to 15V continuous adjustable voltage regulated power supply, the maximum current can reach 10A, the circuit uses a temperature compensation characteristics, high-precision standard voltage source integrated circuit TL431, so that the stability accuracy is higher, if there is no special requirements, It can basically meet the normal maintenance and use, and the circuit is shown in the figure below.

Its working principle is divided into two parts, the first part is a fixed 5V1.5A voltage regulator circuit, the second part is another route 3 to 15V continuous adjustable high-precision high-current voltage regulator circuit.

Its working principle is divided into two parts, the first part is a fixed 5V1.5A voltage regulator circuit, the second part is another route 3 to 15V continuous adjustable high-precision high-current voltage regulator circuit.

The first circuit is very simple, the transformer secondary 8V AC voltage through the silicon bridge QL1 rectified DC voltage through C1 electrolytic capacitor filtering, and then 5V three-terminal regulator LM7805 does not use any adjustment can generate a fixed 5V1A voltage regulator power supply at the output end, this power supply can be used as an internal power supply when the maintenance of the computer board.

The second part is basically the same as the ordinary series voltage regulator power supply, the difference is that the standard voltage source integrated circuit TL431 with temperature compensation characteristics and high precision is used, so the circuit is simplified, the cost is reduced, and the voltage regulator performance is high.

In the figure, the resistor R4, the voltage regulator TL431, and the potentiometer R3 constitute a continuously adjustable constant voltage source, providing a reference voltage for the BG2 base. The voltage regulator TL431 is continuously adjustable, which determines the maximum output voltage of the voltage regulator power supply. If you want to expand the adjustable voltage range, you can change the resistance values of R4 and R3. Of course, the secondary voltage of the transformer should also be increased.

The power of the transformer can be flexibly mastered according to the output current, and the secondary voltage is about 15V. The rectifier tube QL for bridge rectifier uses a 15-20A silicon bridge, which is compact in structure and has a fixing screw in the middle, which can be directly fixed on the aluminum plate of the housing for favorable heat dissipation.

The adjustment pipe is a large current NPN type metal shell silicon tube, because of its large heat, if the chassis allows, try to buy a large heat sink, expand the heat dissipation area, if you do not need a large current, you can also change the power of a small silicon tube, so that the volume can be smaller.

Filter with 50V4700uF electrolytic capacitor C5 and C7 respectively with three parallel, so that the large current output is more stable, in addition, this capacitor to buy a relatively large volume, those smaller volume also marked 50V4700uF as far as possible not to use, when the voltage fluctuations are frequent, or long time not use, easy to fail.

Finally talk about the power transformer, if you do not have the ability to wind yourself, can not buy ready-made, you can buy a ready-made more than 200W switching power supply instead of the transformer, so that the voltage regulation performance can be further improved, the production cost is not too much, other electronic components have no special requirements, after installation without too much adjustment can work normally.

Second, switching power supply

PWM switching power supply integrated control IC-UC3842 working principle

The following figure shows the internal block diagram and pin diagram of UC3842. UC3842 adopts a fixed working frequency pulse width controllable modulation mode, with a total of 8 pins, and the functions of each pin are as follows:

① The foot is the output end of the error amplifier, and the external resistance-capacitance element is used to improve the gain and frequency characteristics of the error amplifier;

The foot is the input end of the feedback voltage, and the voltage of the foot is compared with the 2.5V reference voltage of the error amplifier in the same phase to generate the error voltage, so as to control the pulse width;

③ The foot is the input end of current detection. When the detection voltage exceeds 1V, the pulse width is reduced to make the power supply in intermittent working state;

④ The foot is the timing end, and the operating frequency of the internal oscillator is determined by the external resistance and capacitance time constant, f=1.8/ (RT×CT);

⑤ The foot is the public ground end;

⑥ The foot is the push-pull output end, the interior is the totem pole type, the rise and fall time is only 50ns, the driving capacity is ±1A;

The pin is the DC power supply side, with undervoltage and overvoltage locking function, the chip power consumption is 15mW; The pin is a 5V reference voltage output end, with a 50mA load capacity.

The following describes the internal conceptual diagram of the UC3842.

The following describes the internal conceptual diagram of the UC3842.

UC3842 is a PWM switching power supply integrated controller with excellent performance, wide application and simple structure. Because it has only one output end, it is mainly used for the switching power supply controlled by the voice end.

The UC3842 pin 7 is the voltage input terminal, and its starting voltage range is 16-34V. When the power supply is started, the VCC<16V, the input voltage denser comparator output is 0, then no reference voltage is generated, the circuit does not work; When Vcc>16V, the input voltage Schmidt comparator sends a high level to a 5V ferns regulator, producing a 5V reference voltage that feeds the internal circuit on the one hand and passes through on the other

The pin provides a reference voltage to the outside. Once the Schmidt comparator is flipped to a high level (after the chip has started working), the Vcc can vary in the range of 10V-34V without affecting the operating state of the circuit. When the Vcc is below 10V, the Schmidt comparator flips to a low level and the circuit stops working.

When the reference voltage regulator has a 5V reference voltage output, the reference voltage detection logic comparator reaches a high level signal to the output circuit. At the same time, the oscillator will generate an oscillation signal of f=/ rT. Ct according to the Rt and Ct parameters outside the ④ foot, and this signal will be directly added to the input end of the totem pole circuit

The other one is added to the set end of the PWM pulse width market RS trigger, and the R end of the RS type PWN pulse width modulator is connected to the output end of the current detection comparator. The R end is the duty regulation control end. When the R voltage rises, the pulse width at the Q end is widened, and the pulse width at the ⑥ foot is also widened (the duty ratio increases). When the voltage at the R end drops, the pulse at the Q end narges, and the pulse width at the ⑥ foot also narges (the duty cycle decreases).

The timing sequence of UC3842 points is shown in the figure. Only when point E is at high voltage level, and points a and b are all at high voltage level, point d sends out high level, and point c sends out low level, otherwise point d sends out low level, and point c sends out high level. ② The foot is generally connected to the output voltage sampling signal, also known as the feedback signal. When the 2 foot voltage rises, the 1 foot voltage will drop, and the R terminal voltage will also drop, so the 6 foot pulse will narrow; Conversely, the ⑥ foot pulse widens.

The foot is the current sensing end, usually in the power tube source or emitter string into a small resistance value sampling resistor, the current flowing through the switch tube into a voltage, and this voltage into the foot. When the load is short-circuited or other reasons cause the power tube current to increase, and the voltage on the sampling resistance exceeds 1V, the ⑥ pin stops the pulse output, so that the power tube can be effectively protected from damage.

TOP224P composed of 12V, 20W switching DC power supply circuit

TOP224P composed of 12V, 20W switching DC power supply circuit

The 12V, 20W switching DC regulated power supply circuit composed of TOP224P is shown in the figure.

Two integrated circuits are used in the circuit: TOP224P three-terminal single-chip switching power supply (IC1) and PC817A linear optocoupler (IC2). The AC power supply generates DC high voltage Ui after UR and Cl rectification filter, and supplies power to the primary winding of the high-frequency transformer T.

VDz1 and VD1 can clamp the peak voltage generated by leakage sensing to a safe value, and can attenuate the ringing voltage. VDz1 adopts P6KE200 transient voltage suppressor with 200V reverse breakdown voltage, VDl adopts 1A / 600V UF4005 ultrafast recovery diode.

The secondary winding voltage is rectified and filtered by VLA, C2, Ll and C3 to obtain 12V output voltage Uo. The Uo value is set by the sum of VDz2 stable voltage Uz2, the forward voltage drop UF of the LED in the optocouple, and the voltage drop on R1.

Other output voltage values can be obtained by changing the turn ratio of the high frequency transformer and the voltage regulator value of VDz2. R2 and VDZ25 also provide a dummy load for the 12V output to improve load adjustment at light loads. After the feedback winding voltage is rectified and filtered by VD3 and C4, the bias voltage required by TOP224P is supplied. R2 and VDz2 are used to adjust the current of the control terminal, and the voltage is stabilized by changing the output duty cycle.

The common mode choke L2 can reduce the common mode leakage current generated by the high voltage switch waveform at the D end of the primary winding. C7 is a protective capacitor used to filter out the interference caused by the primary and secondary winding coupling capacitors. C6 can reduce the differential mode leakage current caused by the fundamental and harmonic waves of the primary winding current. C5 not only filters out the peak current applied to the control end, but also determines the self-starting frequency, and it compensates the control loop together with R1 and R3.

The main technical indicators of this power supply are as follows:

The main technical indicators of this power supply are as follows:

-

Ac input voltage range: u=85 ~ 265V;

-

Input grid frequency: fLl=47 ~ 440Hz;

-

Output voltage (Io=1.67A) : Uo=12V;

-

Maximum output current: IOM=1.67A;

-

Continuous output power: Po=20W (TA=25℃, or 15W (TA=50℃);

-

Voltage adjustment rate: η= 78%;

-

The maximum output ripple voltage: ±60mV;

-

Operating temperature range: TA=0 ~ 50℃.

Third, DC-DC power supply

3V to +5V, +12V circuit diagram

Battery-powered portable electronic products generally use low power supply voltage, which can reduce the number of batteries, to achieve the purpose of reducing product size and weight, so generally used 3 ~ 5V as the working voltage, in order to ensure the stability and accuracy of the circuit work, require the use of regulated power supply.

If the circuit uses 5V operating voltage, but another high operating voltage is required, this often makes the designer difficult. This paper introduces a circuit composed of two booster modules which can solve this problem and only needs two batteries.

The circuit is characterized by fewer peripheral components, small size, light weight, output +5V, +12V are stable, to meet the requirements of portable electronic products. The +5V power supply can output 60mA, and the maximum output current of the +12V power supply is 5mA.

The circuit is shown in the figure above. It consists of AH805 booster module and FP106 booster module. AH805 is a booster module with input 1.2 ~ 3V and output 5V, and can output 100mA current at 3V power supply. FP106 is a chip type booster module, input 4 ~ 6V, output fixed voltage of 29±1V, output current up to 40mA, AH805 and FP106 are a level control of the power supply control terminal.

Two 1.5V alkaline battery output 3V voltage input AH805, AH805 output +5V voltage, one of the 5V output, the other input FP106 to produce 28 ~ 30V voltage, after the voltage regulator output +12V voltage.

It can be seen from the figure that as long as the voltage regulator value is changed, different output voltages can be obtained, and the use is very flexible. The fifth pin of FP106 is the control power off end, when the power is turned off, the power consumption is almost zero, when the fifth pin increases the high level of 2.5V, the power supply is switched on; When pin 5 adds low level <0.4V, the power is turned off. Can be controlled by circuit or manual control, if no control is required, the fifth foot and the eighth foot are connected.

Use MC34063 to make 3.6V to 9V circuit diagram

Working status:

-

No load: Input: 3.65V, 18uA (equivalent 600mAH battery standby for more than three years)

-

Load: Output: 9.88V, 50.2mA, input: 3.65V, 186.7mA, efficiency is 72%

How it works:

-

When there is no load, the 6 pin of the IC has no power and stops working, and the 3.65V working current at the input end is only 18uA (equivalent to more than three years of 600mAH battery standby)!

-

When there is a load (Q1 has Ieb current) the EC pole of 8550 is switched on, and the IC is powered to work. Whether the IC works is determined by whether there is a load, which is equivalent to a battery. High voltage conversion efficiency with IC, stable output!

This circuit adds some improvements, and the increased power can be done as "4.2V to 5V mobile power supply without switching". You can use a battery case as a backup power source for your phone!

Fourth, charging circuit

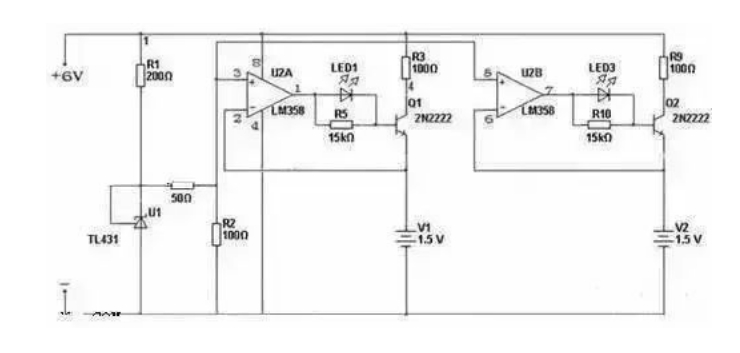

lm358 alkaline battery charger circuit diagram

There are two different versions of whether alkaline batteries can be recharged. Some say can be filled, the effect is very good. Some say that it must not be charged, and the battery indicates that there is a danger of explosion. In fact, alkaline batteries are rechargeable, and the number of charges is generally about 30-50 times.

In fact, due to the mastery of the charging method, it has led to two completely different consequences. First of all, alkaline batteries can be charged is beyond doubt, at the same time, in the battery description, it is mentioned that alkaline batteries are not rechargeable, charging may lead to explosion.

That's also true, but note the word "could" cause an explosion. You can also understand it as a disclaimer of self-protection by the manufacturer. The key to alkaline battery charging is temperature. As long as there is no high temperature when charging the battery, the charging process can be successfully completed, and the correct charging method requires several points:

-

Small current 50MA

-

But charge 1.7V, but put 1.3V

Some people try to charge the practice, firmly said that can not charge, the reason why there is no charge into the electricity, short time, leakage, explosion and other problems, most of the charger problems, if the charger charging current is too large, far more than 50ma, such as some fast charger charging current is more than 200ma, the direct consequence is that the battery temperature is very high, hot to touch, If it's mild, it leaks, if it's severe, it explodes.

Some people use nickel-metal hydride rechargeable battery chargers to charge, low-rated chargers do not automatically stop charging function, long-term charging leads to battery overcharging will also appear leakage and explosion. A better charger has an automatic stop charge function, but the stop charge voltage is generally set to 1.42V of the nickel-metal hydride rechargeable battery, and the alkaline battery full voltage is about 1.7V.

Therefore, the voltage is too low, and the feeling is that the electricity cannot be charged, the electricity consumption time is short, and the effect is not good. Another is the battery, but put refers to do not wait until the battery is completely out of power and then charged, so the operation, the best battery can be charged three or five times, and the effect is poor.

It is generally recommended to use Nanfu alkaline battery voltage is not less than 1.3V. Therefore, if you plan to charge the alkaline battery, you must have a qualified charger, the charging current is about 50ma, and the charging cut-off voltage is about 1.7V. Take a look at your charger.

There are alkaline battery chargers on the market, the so-called patented products. It is actually a simple circuit with a charging voltage of 1.7V and a current of 50ma. Using the existing parts LM358 and TL431 at hand, I made a simple circuit with a cut-off voltage of 1.67V and automatic stop charging, which cost only two yuan. For interested friends reference.

Related instructions:

Alkaline manganese rechargeable battery: It is developed on the basis of alkaline zinc manganese battery, due to the application of mercury-free zinc powder and new additives, it is also known as mercury-free alkaline manganese battery. This battery does not change the original alkaline battery discharge characteristics at the same time, and can be charged dozens of times to hundreds of times, more economical.

Alkaline zinc-manganese battery is referred to as alkaline manganese battery, which was developed in 1882, developed in 1912, and put into production in 1949. It has been found that when KOH electrolyte solution is used instead of NH4Cl as electrolyte, both the electrolyte and the structure are greatly changed, and the specific energy and discharge current of the battery can be significantly improved.

Its features:

Its features:

-

Open circuit voltage is 1.5V;

-

The operating temperature range is wide between -20 ° C and 60 ° C, suitable for use in high-cold areas;

-

The capacity of high current continuous discharge is about 5 times that of acid zinc-manganese battery.

-

Its low temperature discharge performance is also very good. The number of charging is within 30 times, generally 10-20 times, and special chargers are required, which is extremely easy to lose charging ability.

2.75W medium power USB charger circuit diagram

The design uses Power Integrations' LinkSwitch family LNK613DG. This design is ideal for mobile phones or similar USB charger applications, including mobile phone battery chargers, USB chargers or any application that requires constant voltage/constant current characteristics.

In the circuit, diodes D1 to D4 rectify the AC input, and capacitors C1 and C2 filter the DC. L1, C1 and C2 form a π-type filter to attenuate differential mode conducted EMI noise. Are these transformers E-sheild with Power Integrations? The combination of technologies enables this design to easily meet the EN55022 B-class conducted EMI requirements with sufficient margin and without the need for a Y capacitor. The fireproof, fusible, wire-wound resistor RF1 provides severe failure protection and limits the surge current generated during start-up.

The U1 is powered by an optional bias supply, which reduces no-load power consumption to less than 40 mW. The value of the bypass capacitance C4 determines the amount of cable voltage drop compensation. A value of 1μF corresponds to compensation for a 0.3Ω, 24 AWG USB output cable. (The 10 μF capacitor compensates the 0.49 Ω, 26 AWG USB output cable.)

The U1 is powered by an optional bias supply, which reduces no-load power consumption to less than 40 mW. The value of the bypass capacitance C4 determines the amount of cable voltage drop compensation. A value of 1μF corresponds to compensation for a 0.3Ω, 24 AWG USB output cable. (The 10 μF capacitor compensates the 0.49 Ω, 26 AWG USB output cable.)

In the constant voltage phase, the output voltage is regulated by switching control. The output voltage is maintained by skipping the switching cycle. By adjusting the ratio of enable to disable periods, the voltage can be maintained. This also allows the efficiency of the converter to be optimized over the entire load range. Under light load (trickle charge) conditions, the current limiting point is also reduced to reduce the transformer flux density, thereby reducing audio noise and switching losses. With the increase of the load current, the current limiting point will also increase, and fewer and fewer cycles will be skipped.

When no more switching cycles are skipped (the maximum power point is reached), the controller within the LinkSwitch-II switches to constant current mode. When the load current needs to be further increased, the output voltage will decrease accordingly. The drop in output voltage is reflected in the FB pin voltage. In response to the FB pin voltage drop, the switching frequency will drop linearly to achieve a constant current output.

D5, R2, R3, and C3 comprise the RCD-R clamping circuit, which is used to limit drain voltage spikes caused by leakage induction. Resistor R3 has a relatively large value to avoid the drain voltage waveform oscillation caused by leakage induction, which prevents excessive oscillation during shutdown, thereby reducing conducted EMI.

Diode D7 rectifies the secondary and C7 filters it. Together, C6 and R7 can limit transient voltage spikes on D7 and reduce conducted and radiated EMI. The resistor R8 and the Zener diode VR1 form an output dummy load that ensures that the output voltage is within an acceptable limit when unloaded and that the battery is not fully discharged when the charger is disconnected from the AC mains. Feedback resistors R5 and R6 set the maximum operating frequency and output voltage during the constant voltage phase.

5. Constant current source

How to design three-wire constant current source driving circuit

The constant current source driving circuit is responsible for driving the temperature sensor Pt1000, converting the resistance signal sensed by it with the change of temperature into a measurable voltage signal. In this system, the required constant current source should have the characteristics of constant output current, good temperature stability, large output resistance, output current less than 0.5mA (the upper limit of Pt1000 without self-heating effect), grounding at one end of the load, and changing the polarity of the output current.

Because the influence of temperature on the parameters of integrated op amp is not as significant as that on the parameters of transistor or FET, the constant current source composed of integrated op amp has the advantages of better stability and higher constant current performance. Especially in the case that the load end needs to be grounded, it has been widely used. Therefore, the dual op amp constant current source shown in Figure 2 is adopted. The amplifier UA1 constitutes the adder and UA2 constitutes the follower. The low noise, low offset and high open loop gain bipolar operational amplifier OP07 is selected for both UA1 and UA2.

In the figure above, the potentials of the upper and lower ends of the reference resistance Rref are Va and Vb respectively, Va is the output of the same adder UA1. When the resistance R1=R2, R3=R4, Va=VREFx+Vb, so the output current of the constant current source is:

In the figure above, the potentials of the upper and lower ends of the reference resistance Rref are Va and Vb respectively, Va is the output of the same adder UA1. When the resistance R1=R2, R3=R4, Va=VREFx+Vb, so the output current of the constant current source is:

It can be seen that the dual op amp constant current source has the following significant characteristics:

-

The load can be grounded;

-

When the operation amplifier is powered by two power supplies, the output current is bipolar.

-

The constant current size is achieved by changing the input reference VREF or adjusting the reference resistance Rref0, which makes it easy to obtain a stable low current and compensation calibration.

Due to the mismatch of resistance, the voltage at both ends of the reference resistor Rref0 will be affected by the terminal voltage Vb of its driving load. At the same time, because it is a constant current source, Vb will certainly change with the load, which will affect the stability of the constant current source. Obviously this is not acceptable for high precision constant current sources. Therefore, the selection principle of the four resistors R1, R2, R3 and R4 is that the mismatch should be as small as possible, and the mismatch size of each pair of resistors should be consistent. In practice, a large number of precision resistors of the same batch can be screened and 4 resistors with similar resistance values can be selected.

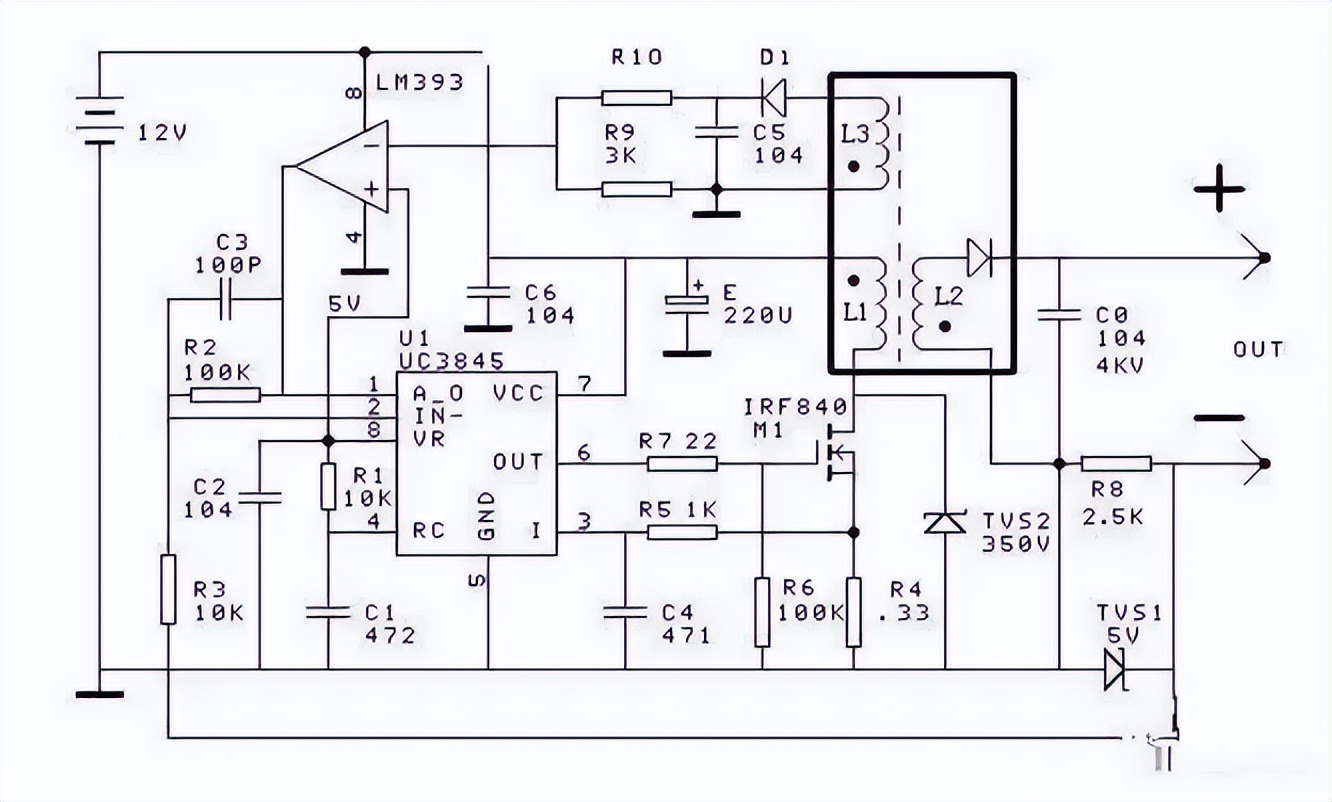

Switching power supply type high voltage constant current source circuit diagram

The development instrument needs a constant current source that can generate 1MA current on a resistance of 0 to 3 meghm, which is designed with UC3845 combined with a 12V battery. The transformer adopts a color TV high voltage pack, in which L1 uses enamoured wire to wind 24 turns on the magnetic core of the original high voltage pack, L3 uses a coil of the original high voltage pack, and L2 uses the high voltage part of the high voltage pack. L3 and LM393 form a voltage limiting circuit to limit the output voltage from being too high, and adjusting R10 can adjust the open circuit output voltage.