The cause of non-standard EMC formation and design corrective measures

2024-05-30 10:02:26 1071

Electromagnetic compatibility (EMC) is a measure of how a device or system behaves in an electromagnetic environment. The EMC level of electronic products needs to pass a series of standardized EMC assessment 1-2 tests. In order to enable electronic products to reproduce the same EMC test conclusions and their ability to have the same EMC level in a similar electromagnetic environment, the relevant fields or enterprises have developed standardized rules and regulations or specifications for electronic products, including equipment installation and configuration requirements. EMC equipment that complies with this regulation or specification, such as test levels and methods, can be called EMC equipment.

When the installation and use of electronic products expand into the global industrial field, due to different installation standards, different user habits, and different electromagnetic environments, will the equipment still have electromagnetic compatibility? The self-evident conclusions are questionable.

Causes of non-standard EMC

Taking the current industrial electronic products as an example, in order to meet the practical and strong level of electromagnetic compatibility, field EMC has been developed including test specifications, EMC assembly equipment and application specifications 5-5. Generally has the characteristics of universality and ideal:

1) EMC laboratory test and evaluation environment;

2) EMC test is the equipment installation and configuration requirements of the system grounding:

3) Sensitive high-speed signal shielding cable shielding layer is well grounded.

However, different customers may have one or more deviations from the ideal environment due to actual application costs, assembly constraints and other factors:

① There is no ground point in the equipment installation site;

② Power supply is not grounded or can not be grounded:

(3) High-speed signal cables that are particularly sensitive to the cable are not shielded, or shielded but not grounded.

The above non-standard EMC configurations are called non-standard EMC configurations. The EMC evaluation and testing of the corresponding configuration of this non-standard EMC is called non-standard EMC Non-standard test EMC test results are the carrier of the EMC design of the equipment, and the rectification measures are called non-standard EMC measures.

Most applications of the equipment meet standard EMC requirements, with one exception of non-standard EMC. Therefore, non-standard. EMC can be regarded as part of the specification EMC filling and optimization can not be used as a separate way and method to get rid of the standard EMC structure EMC specification design and rectification measures EMC design rectification measures, then implement and improve. Therefore, non-standard EMC design and rectification measures are also based on the conclusion that the non-standard EMC is considered together.

Standard non-standard EMC design and rectification measures are equivalent to standard or non-standard treatment equipment EMC operation faults affecting the environment are equivalent to floods. At the beginning of planning, that is, schematics and schematics. PCB perfect design specifications Non-standard EMC design can prevent and deal with the vast majority of electromagnetic compatibility which is the lowest cost governance between the problems.

The modification in EMC testing is only the repair and improvement after the flood. Fluctuation is the root cause of error, reducing or eliminating fluctuation is the principle of governance. EMC design and countermeasures have three methods: thinning, blocking and treatment.

One of EMC countermeasures: thinning

Dredging is done by reducing the impedance in other ways, thereby reducing the impact of the current entering the sensitive circuit3. It is divided into two kinds: dirty land protection and weak land protection

1. Dirty maintenance

Dirty ground maintenance should take the ground plane as the basic way, and bypass affects the current, so it is also called dirty ground. The method should be developed before planning the corresponding plan, the cost is limited under PCB specifications. All possible impacts from all systems are assessed, but for non-standard systems, EMC, the fewest physical channels between all cable sockets include all affected components.

The first step is to clarify the way of dirty ground, that is, the path from the influence channel to the intermediate PCB internal reference ground and the PE protection area, so that it avoids the sensitive area. The following countermeasures can be taken:

(1) There should be a capacitor from the cable socket to the reference ground or the E plane to determine this capacitor, and the crossover capacitor part between the Y capacitor and different areas makes the dirty ground as short as possible to avoid signal wiring and chips in sensitive areas such as protection, control and communication.

(2) If the PCB is divided into multiple protection areas, a certain crossover capacitor or Y capacitor is needed to avoid affecting the probability of current flow to the power line.

(3) Embedded cable multiple socket capacitors, Y according to the chip, protection device, power line decoupling or all over the capacitive coupling, improve the candidate's dirty way to prevent impact. EMC design needs to understand this even more.

(4) Non-standard EMC dirty ground also includes the signal and power plane near the power cable jack.

(5) Sensitive signal wiring and countercurrent should be away from all predictable influence paths, and the smaller the part that is parallel or overlapping with the influence path, the better.

(6) The non-standard EMC cable interface empty pin increases the capacitor, which can increase the additional impact on the drainage channel.

(7) Non-standard EMC tries to avoid the total number and length of signal cables, which can effectively reduce the current affected by the flow of PCB.

The second step is to reduce the dirty ground impedance as much as possible, so that it drains most of the affected current. The following countermeasures can be taken:

(1) The reference ground plane and PE plane of each area of the PCB should be large enough to prevent termination or slotting, the number of layers should be sufficient, and the position near the solid through-holes, especially the cable sockets (that is, affecting the current exit) should be sufficient and comprehensive to ensure low impedance.

(2) Pay attention to surface PE due to the skin effect of the surface plane of the effect of higher current, plane and continuity.

(3) Non-standard EMC dirty ground also includes the power plane, so it is necessary to understand the integrity of the Shenyuan plane, especially near the cable plug, to ensure low impedance.

(4)Y capacitor, cable interface capacitor and jumper capacitor on both sides to the ground power supply, PE plane or power line impedance should be as small as possible.

(5) Non-standard EMC raising or expanding Y capacitance may be counterproductive. Because it enlarges the Y capacitor's influence current. Therefore, do not blindly place or increase the Ya capacitor, and try to remove unnecessary Y capacitors. The Y capacitance value near the power cord socket should be as small as possible during standardized EMC tests.

2. Protect the weak and reject the strong

Weak rather than strong: in other error-free or strong interference resistance circuit (such as filter effect, high voltage) area, according to the coupling mode of Y capacitor or jumper capacitor, add additional influence drainage mode to reduce the impact separation of the affected area. It should be noted that there is no need to affect the normal operation of the introduction section. Or to add ground capacitors to other non-impact hazard signals in the same area, the capacitor portion should be close to the cable socket, and non-standard EMC design needs to understand this.

EMC solution 2: Traffic is blocked

This is only an alternative and whether or not to adopt the EMC evaluation test conclusions should be based on reality. Remember not to turn strength into weakness. Instead, clogging and correction are reduced by amplifying the influence path impedance in the sensitive area. According to the influence current of the path 5, it can be divided into population blockage and outlet blockage.

1. The channel is blocked

If the channel is blocked, the impedance is expanded on the necessary path affecting the source of current introduction. This scheme requires impedance in schematics and schematics. PCB design considerations:

(1) Sensitive signal enhancement isolation measures, through light, capacitive coupling or magnetic coupling isolation methods to improve the path impedance;

(2) Reduce or remove the physical capacitance spread across the received sensitive area:

(3) Add common-mode inductors and magnetic beads to the power supply and its signal connection

(4) Non-standard EMC inevitably affects the discharge of current from the signal cable, so the power line needs to have adequate filtering countermeasures, such as RC, LC, common mode inductance, etc. The capacitor in the power line should be as close as possible to the cable socket to prevent the influence current and the sensitive signal wiring overlap.

2. The exit is blocked

When the outlet is blocked, the impedance increases to the area that affects the flow of current from the sensitive circuit. The scheme is commonly used for equipment. EMC made the following corrections to the impact issues in the test:

1) Increase the common mode inductance and small resistance of magnetic beads at the affected hazard signal inlet and outlet;

2) For non-standard EMC, the above equipment should be added between the power line decoupling capacitor or protection device and the cable jack.

EMC Strategy three: Treatment

According to the overlap between the wiring and the dirty ground path, and the phenomenon that the wiring itself affects the path, the capacitance should be increased or reduced, and the resistance should be increased in the middle of the inductor or magnetic bead that affects the high resistance of the frequency band. The signal wiring around the EMC signal jack must add a large enough capacitor, while reducing the PCB signal wiring and signal cables affect the current in high frequency bands, and can also be series resistors, inductors or magnetic beads behind the capacitor. Treatment of headache, foot pain, where there is a problem add capacitors or series resistors, this program is suitable for rectification, generally in EMC when there are problems in the test, rectification is carried out:

1) Increased capacitor, resistance should overlap with the influence current;

2) The capacitor is not the larger the better, should choose the equivalent series inductance plus signal wiring equivalent inductance form, the resonant frequency of the capacity value in the influence of the working band;

3) The root cause of the error is the ground level noise, and the capacitor can not definitely deal with the problem;

4) Non-standard EMC, expanding the capacitance around the signal socket can be counterproductive because it amplifies the effect on the current in the signal. Therefore, a suitable capacitance value should be selected, or a string of resistors, magnetic beads, etc., after the capacitor.

EMC Strategy Summary

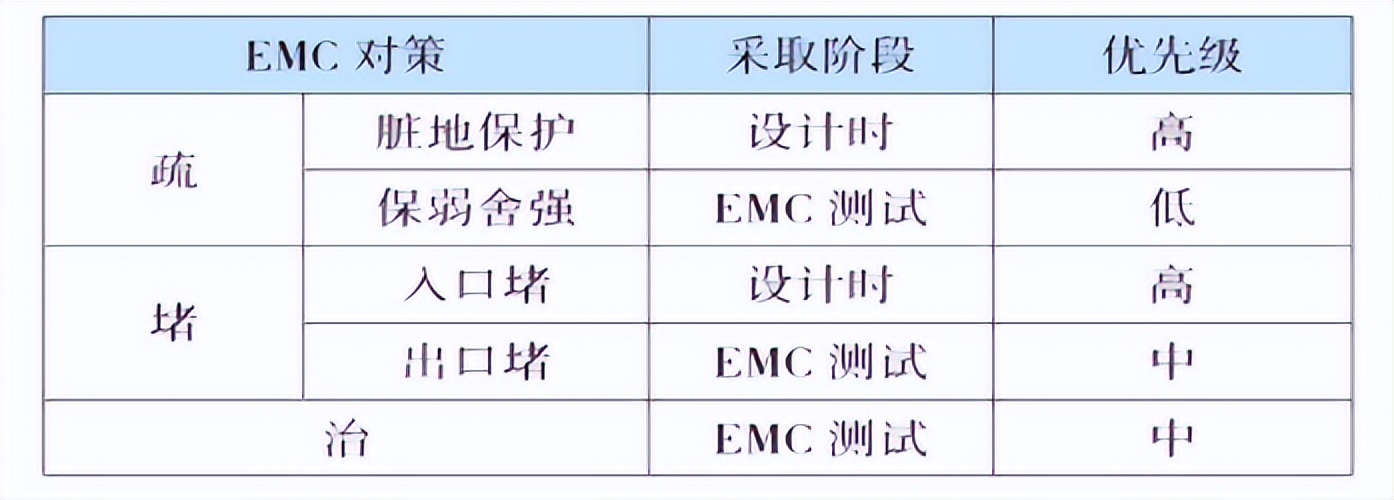

The various EMC designs and rectification measures in this paper, the links taken and their priorities are shown in Table 1.

Table 1. Stages of EMC countermeasures and recommendations

It is recommended to use the equipment development design EMC evaluation and design process, as shown in Figure 1.

Figure 1. Standard & Non-standard EMC evaluation design process

EMC test and rectification procedure Figure 2 shows the EMC rectification procedure

Figure 2. Standard & Non-standard EMC test rectification process

Figure 2. Standard & Non-standard EMC test rectification process

peroration

Through the analysis of non-standard EMC, it can be seen that most of the general EMC design and rectification countermeasures can also be applied to non-standard EMC, but some standard EMC countermeasures will also increase the risk of non-standard EMC, and non-standard EMC also has special attention in electronic design. When evaluating the performance of EMC in product design, it is not only necessary to consider its performance in standard EMC, but also to evaluate its capability in non-standard EMC. Some equipment with a wide range of applications, more complex use environment and operation mode need to increase the design and testing of non-standard EMC. Non-standard EMC is the supplement and perfection of standard EMC. The application of non-standard EMC enables the equipment to show strong electromagnetic compatibility and applicability in a more complex and harsh electromagnetic environment, so as to effectively improve the technical advantages and product competitiveness of the equipment.