How to properly install and maintain proximity sensors?

2024-09-26 15:04:53 1219

catalogue

1. This topic describes the proximity sensor

1.1 What is a Proximity sensor?

1.2 Common proximity sensor types and their working principles

2. What industries or occasions can proximity sensors be used in?

3. How to choose the right proximity sensor according to the needs

4. Install the proximity sensor and take precautions

5. How to perform daily maintenance of the proximity sensor

6. Troubleshooting

6.1 What Are the Common Faults of the Proximity sensor?

6.2 How do I diagnose and resolve a fault in the proximity sensor?

7. What are the advantages and disadvantages of proximity sensors compared to other types of sensors?

If you've ever had trouble choosing or using proximity sensors, you've come to the right place. In fact, the correct understanding and application of proximity sensors in automation systems and electronic devices is very critical. Failure to understand their working principle and applicability may lead to inaccurate detection, system instability and even security risks. But don't worry, I'm going to walk you through the basics of proximity sensors in an easy-to-understand way, including their various types, how they work, and how to pick the right sensor for your specific needs.

1. This topic describes the proximity sensor

1.1 What is a Proximity sensor?

Proximity sensor is an electronic device that can detect whether an object is close to its sensing surface, and it can detect whether an object is close to its sensing surface without actually touching the object. It senses changes in the surrounding environment and converts these changes into electrical signals, which are then transmitted to the control system for use. Such sensors operate on a variety of principles and can be based on physical phenomena such as electromagnetic fields, capacitive effects, photoelectric effects, or ultrasonics.

One of the main features of this sensor is the non-contact mode of operation, which means that they can work properly without directly touching the object under test. At the same time, proximity sensors are very responsive and can quickly respond to the presence of objects. Because there are no wear problems with mechanical components, these sensors are very durable and have a long service life. In addition, the proximity sensor can also be well adapted to a variety of environmental conditions, even in harsh industrial environments can work reliably.

1.2 Common proximity sensor types and their working principles

Understanding the working principle of different types of proximity sensors can choose the appropriate proximity sensor according to the nature of the object being measured or the specific application scenario.

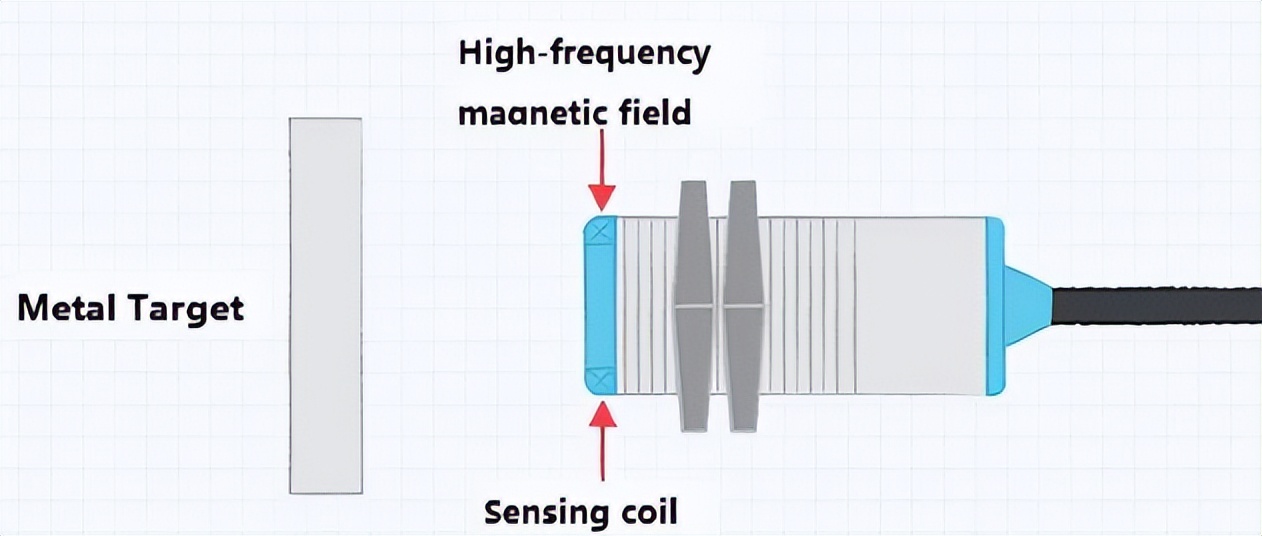

Inductive proximity sensor:

Inductive proximity sensors are mainly used to detect metal objects. It contains an oscillating circuit that generates an alternating magnetic field.

When a conductive metal object enters this magnetic field, an eddy current is induced inside the object. The eddy current changes the state of the oscillating circuit (usually by reducing the oscillation frequency or stopping the oscillation). This change is translated into an output signal indicating that an object is approaching.

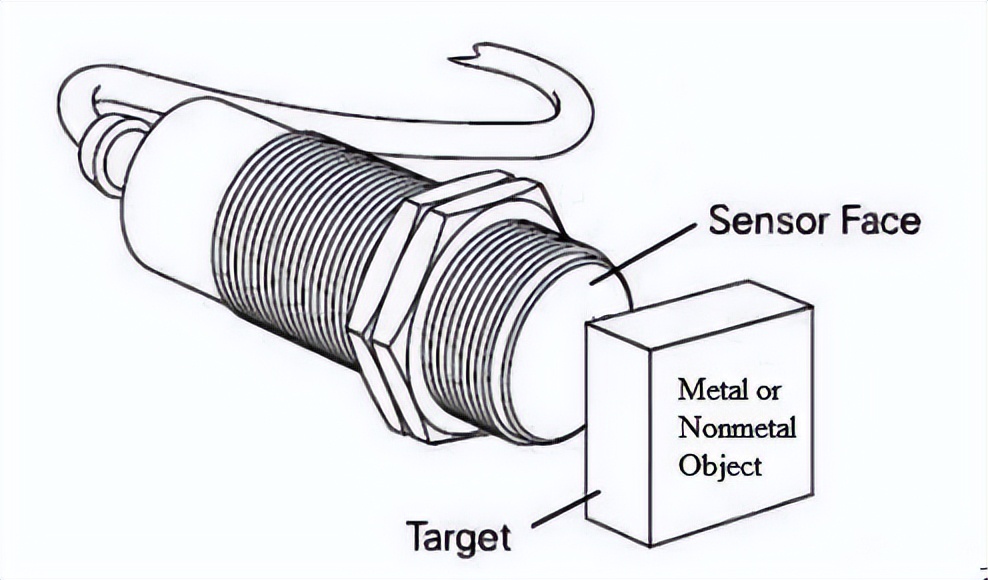

Capacitive proximity sensor:

Capacitive proximity sensors can detect any object that can change the distribution of electric fields, including non-metallic materials.

Inside the sensor is a capacitor, consisting of two plates. When no object is approaching, the capacitor maintains a certain capacitance. When the object approaches, it changes the permittivity between the two plates, thus changing the capacitance. The change in capacitance is converted into an electrical output.

Photoelectric proximity sensor:

Photoelectric proximity sensors use light beams to detect objects. They can be a dual type with separate transmitter and receiver, or a reflective type with a reflector.

In a beam sensor, a signal is generated when an object blocks the path of light from the transmitter to the receiver. Reflective sensors use light reflected back from a target object to trigger a signal.

Ultrasonic proximity sensor:

Ultrasonic sensors measure distance by sending and receiving ultrasonic pulses. The transmitter emits ultrasonic waves, which encounter objects and are reflected back to the receiver.

The distance of the object is calculated from the time difference between the sound and the return. The shorter the time, the closer the object is; And vice versa.

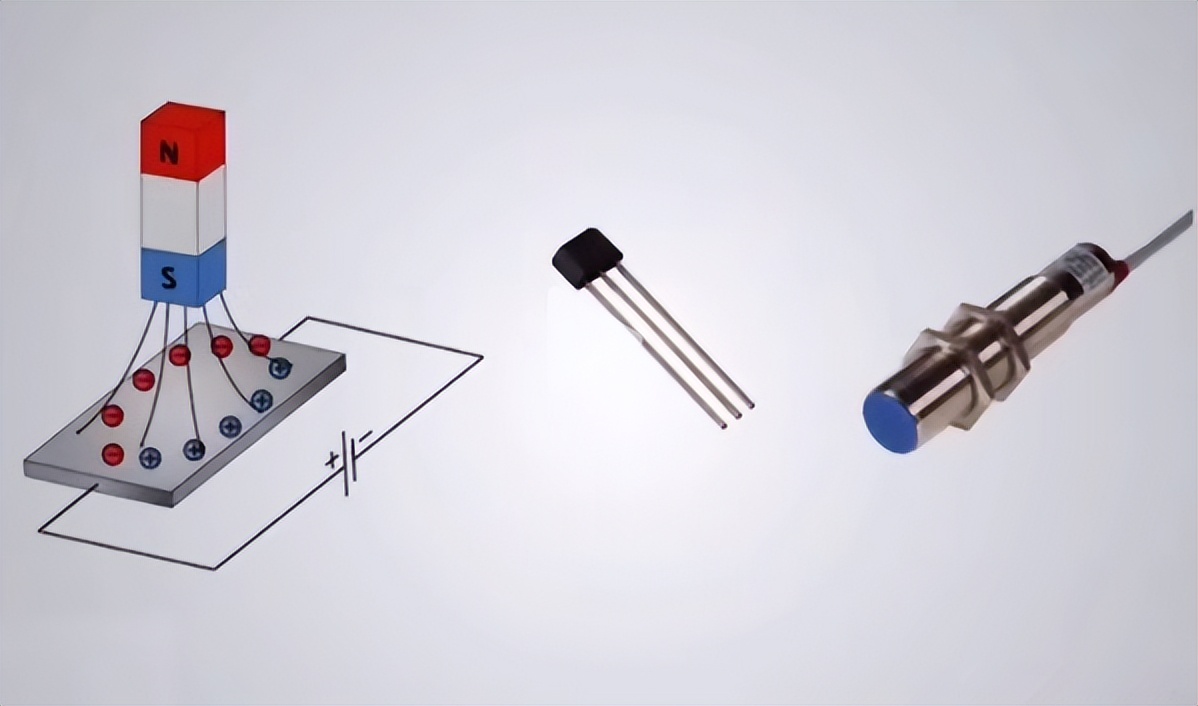

Hall effect proximity sensor:

Hall effect sensors are used to detect the presence or absence of magnetic fields. They are commonly used to detect the position of magnetic objects.

When the magnet is near the sensor, the magnetic field will cause the electrons in the sensor to shift, creating a Hall voltage. This voltage is converted into an output signal indicating the position of the magnet.

2. What industries or occasions can proximity sensors be used in?

Manufacturing: Used in automated production lines to detect the presence, location and counting of workpieces. Anti-collision protection of the robot arm ensures safe operation. Material inspection and control in material handling equipment.

Automotive Industry: Intrusion detection in vehicle anti-theft systems. Obstacle detection with astern radar and parking assist system. Crankshaft position sensing for engine management systems.

Packaging industry: Product presence detection and alignment on packaging machines. Ensure proper filling and seal quality during packaging.

Logistics & Warehousing: Tracking the location of goods in automated warehouses. Package or pallet detection on conveyor belt.

Food and beverage industry: Detection of the position of bottles or cans on production lines. Check that the seal is intact.

Electronics and Semiconductor Manufacturing: Precise position control during semiconductor wafer processing. SMT (Surface Mount Technology) component placement monitoring on the assembly line.

Building and security monitoring: personnel access sensing in the access control system. Elevator floor selection button under touch sensing.

Healthcare: Level control in medical devices. Recovery robot tracking the movement of patients.

Smart home: The function of hand waving on and off lights in smart lighting system. Motion detection from home security cameras.

Agriculture: Position awareness for crop row spacing adjustment on agricultural machinery such as planters and harvesters. Soil moisture monitoring for irrigation systems.

In short, any situation that requires automatic detection of object position, motion state, or environmental changes can consider the use of proximity sensors.

3. How to choose the right proximity sensor according to the needs

Selecting the right proximity sensor requires a combination of factors to ensure that the selected sensor can meet the needs of the specific application.

Here are some steps and suggestions to help you choose the most appropriate proximity sensor for your needs:

Determine the detection object

-

Determine what material (metal, non-metal, liquid, etc.) is being tested, as different sensors may have different sensitivities to different materials.

-

Understand the size and shape of the object under test, which will affect the choice of sensor and the installation location.

Determination of detection distance

-

Determine the minimum and maximum operating distance between the sensor and the measured object.

-

If the application scenario involves a fast-moving target, you need to choose a sensor that responds quickly.

Consider environmental conditions

-

Verify that the ambient temperature at which the sensor will operate is within its operating range.

-

Assess the humidity of the site and whether there will be water splashing or other liquid contact, and select a sensor with the appropriate IP rating accordingly.

-

In high vibration or shock environments, choose a sensor with good vibration resistance.

-

In areas where there is a strong magnetic or electric field, a sensor with good shielding effect should be selected.

Output signal type

-

Such as NPN or PNP type transistor output, suitable for simple switching state indication.

-

Provides continuously varying voltage or current signals for applications requiring accurate measurement.

-

Some advanced sensors may support serial communication protocols (such as RS-485, CAN, Modbus, etc.) for easy integration into complex control systems.

Installation methods and space limitations

-

Ensure that the dimensions of the sensor meet the requirements of the installation space.

-

Consider whether to use screws, magnetic bases, or other mounting methods.

Economic budget

-

Take into account overall costs, including purchase costs, maintenance costs, and potential replacement costs.

-

The cost-effectiveness of long-term operations is also an important consideration.

Other special requirements

-

For some industries (such as food processing, pharmaceuticals, etc.), sensors may also be required to pass specific safety or hygiene certifications.

-

Choose reputable suppliers and ensure timely technical support and service is available.

Test and verification

-

Before the final decision is made, if possible, samples can be obtained for testing to verify that their performance in practical applications meets expectations.

4. Install the proximity sensor and take precautions

Proper installation of proximity sensors is essential to ensure their performance and long-term reliability. Different types of proximity sensors may have different installation requirements, but here are some general guidelines:

a. Determine the installation position

-

Avoid interference: Choose a location away from strong magnetic fields, electric fields and other potential sources of interference.

-

Appropriate detection distance: Ensure that the installation location provides the required minimum and maximum detection range. Take into account the path of motion of the object and any possible mechanical vibrations or deviations.

b. Prepare the installation surface

-

Smooth and clean: Ensure that the installation surface is smooth and clean to ensure good contact and stable working condition.

-

Material compatibility: Check that the material on the mounting surface is suitable for the requirements of the selected sensor, especially for sensor types with different sensitivities to magnetic and non-magnetic materials.

c. Secure the sensor

-

Screw fixation: Most industrial-grade proximity sensors come with standard threaded holes that can be fixed directly to metal plates or other sturdy structures by screws.

-

Bracket or clamp: Use a dedicated bracket or clamp to adjust the Angle and height of the sensor, which is useful in some applications where flexible positioning is required.

-

Magnetic base: Some small sensors may have a magnetic base that can be attached directly to the iron surface for quick installation and adjustment.

d. Connect cables

-

Proper wiring: Connect the power and signal wires according to the wiring diagram provided by the manufacturer. Note the distinction between positive and negative poles and the output signal type (NPN/PNP).

-

Protect cables: If the sensor is located near moving parts or exposed to harsh environments, consider using protective bushings or cable troughs to protect cables from damage.

e. Adjustment and calibration

-

Initial setting: Adjust sensor parameters such as sensitivity and response time according to application requirements.

-

Test run: A preliminary test is carried out after installation to confirm that the sensor can accurately and reliably detect the target, and the output signal is normal.

f. Security and maintenance

-

Regular inspection: Check the sensor and its surrounding environment regularly to remove dust, oil and other factors that may affect performance.

-

Compliance: Ensure that installations comply with all relevant safety standards and industry codes, especially in hazardous areas or where there are special requirements.

Special note

-

Read the instructions: Each sensor has its own characteristics, so be sure to carefully read and follow the specific instructions in the manufacturer's user manual.

-

Professional Help: If you are not sure how to properly install or configure the sensor, you can seek professional technical support or consulting services.

By following the above steps, you can ensure that the proximity sensor is properly installed and will work efficiently. Proper installation not only helps to improve the overall efficiency of the system, but also extends the service life of the sensor.

5. How to perform daily maintenance of the proximity sensor

The daily maintenance of proximity sensors is essential to ensure their long-term stable operation and extended service life. Regular cleaning is the basis of maintenance, should use a clean, dry soft cloth or special detergent to clean the sensor sensor sensor surface, remove dust, oil and other impurities, and keep the shell clean to avoid contact with corrosive substances. Check installation stability, including tightening all setting screws to prevent loosening due to vibration, and verify that the bracket and fixture are firmly held in place. At the same time, the electrical connection is also the focus of the inspection, it is necessary to ensure that the connection of the power cord and signal line is tight and correct, and the insulation layer of the wire is intact to prevent short circuit or other electrical faults.

Environmental conditions have an important impact on sensor performance, so it is important to monitor the temperature and humidity of the operating environment to ensure that they are within the permissible operating range, and to assess whether the IP protection level is adequate based on actual conditions. It is also critical to conduct regular functional tests to verify that the sensor can properly detect the target object and correctly output the signal through response tests, and adjust the sensitivity Settings to adapt to changing operating conditions if necessary. A detailed maintenance log is set up to record the time, content, and problems of each maintenance, which helps to analyze and take corrective measures. In addition, follow the specific maintenance instructions and recommendations in the user manual provided by the manufacturer, replace the worn parts with the original factory recommended parts, and maintain a certain number of critical spare parts in stock in case of unexpected failures.

In order to ensure the effectiveness of the maintenance work, the staff responsible for the maintenance and operation of the sensors should also be provided with the necessary training, so that they understand the correct use methods and maintenance procedures, and enhance their safety awareness, especially when handling live equipment to take extra care. It is recommended to keep the technical support contact information of the manufacturer or supplier, so that you can ask for help in time when you encounter complex problems. These comprehensive measures can effectively reduce the failure rate of proximity sensors, improve the overall reliability and productivity of the system, while also identifying potential problems in advance and taking preventive measures, thereby avoiding unnecessary downtime and maintenance costs.

6. Troubleshooting

6.1 What Are the Common Faults of the Proximity sensor?

Proximity sensors can experience various failures during use, and understanding these common problems can help diagnose and resolve problems quickly.

Here are some common failures of proximity sensors and their possible causes:

No output signal

-

Power supply problem: Check whether the power supply of the sensor is normal, including whether the voltage meets specifications and whether the cable connection is correct.

-

Damage or aging: The internal components of the sensor may be aged or damaged due to long-term use.

-

Induction surface pollution: If the induction surface is covered with dust, oil and other impurities, it may affect its performance.

The output signal is unstable

-

Interference: Electromagnetic interference (EMI) or other external factors may cause the signal to fluctuate.

-

Loose installation: The sensor is not securely installed, causing the distance from the measured object to change.

-

Environmental conditions: Changes in temperature and humidity may affect the stability of the sensor.

The detection distance becomes shorter

-

Reduced sensitivity: The sensor may lose sensitivity due to aging or damage.

-

Target material changes: Different materials respond differently to the sensor, and if the material of the detected object changes, it may be necessary to readjust the Settings.

-

Environmental factors, such as metal obstacles or strong magnetic fields, may affect the effective detection range of the sensor.

False trigger

-

High sensitivity: The sensitivity setting of the sensor is too high and is susceptible to small changes.

-

Vibration: Mechanical vibration may cause the sensor to mistake an approaching object.

-

Environmental interference: such as changes in light, temperature fluctuations, etc., may cause misoperation of photoelectric sensors.

Complete failure

-

Physical damage: The sensor is hit or squeezed, resulting in damage to the internal components.

-

Overvoltage/overcurrent: Improper power connections or short circuits can cause internal circuits to burn out.

-

Extreme environment: Prolonged exposure to an environment outside the operating temperature range or too humid may cause the sensor to completely fail.

Electrical connection problem

-

Wiring error: The positive and negative terminals are incorrectly connected or improperly connected, which will cause the sensor to fail to work properly.

-

Cable damage: If the cable connected to the sensor is damaged, the signal transmission may be interrupted.

Communication failure

-

Interface problems: For sensors that support digital communication, the interface Settings may be incorrect or the communication protocol does not match.

-

Software configuration: Improper setting of relevant parameters in the control system will also affect the data reading of the sensor.

When encountering any of the above faults, you should first determine the problem according to the symptoms, and check according to the corresponding troubleshooting steps.

6.2 How do I diagnose and resolve a fault in the proximity sensor?

When the proximity sensor fails, it can be diagnosed and resolved through a series of methodical steps.

Below are some common diagnostic methods and possible solutions summarized by INFINITECH:

Preliminary inspection

-

First check whether the power supply voltage is normal, make sure that the sensor is correctly connected and the positive and negative terminals of the power supply are not reversed.

-

Check whether the sensor has obvious physical damage, such as cracks, deformation, etc.

-

Verify that the working environment is within the allowable range of the sensor, including temperature, humidity, vibration and other factors.

Clean sensing surface

-

Use a clean soft cloth or special detergent to gently wipe the induction surface to remove dust, oil and other impurities, which can sometimes solve the problem caused by pollution.

Check installation stability

-

Ensure that the sensor and its bracket are firmly fixed to avoid misoperation or unstable signals caused by loosening.

-

Check whether there are moving parts or other objects in the vicinity that interfere with the work of the sensor.

Test output signal

-

Use a multimeter: Measure whether the output of the sensor has the expected electrical signal change. For digital output, it is usually switched; For analog outputs, you should see a voltage or current value that varies with the detection distance.

-

Replacement test: If conditions permit, you can try to replace a new sensor to determine whether the problem is in the sensor itself.

Adjust Settings

-

If the sensor has an adjustable sensitivity, try adjusting the sensitivity setting to see if you can improve performance.

-

For photoelectric sensors, check for light occlusion or poor reflection and adjust the position or recalibrate accordingly.

Exclusion of electromagnetic interference

-

Check for strong magnetic fields, electric fields, or other potential sources of electromagnetic interference near the sensor.

-

Try to move the sensor away from these sources of interference, or take shielding measures to reduce the impact.

Consult manuals and technical support

-

Refer to the user manual or technical documentation provided by the manufacturer for specific guidance on troubleshooting.

-

If the above steps do not solve the problem, contact the supplier or manufacturer's technical support department for help.

Recording and analysis

-

Prior to any repair or replacement, a record of all observed phenomena as well as changes made is very useful for subsequent analysis and reporting.

-

Analyze the root cause of the failure so that preventive measures can be taken in the future, such as improving installation methods and strengthening maintenance.

By systematically performing these steps, most common faults close to the sensor can be effectively diagnosed and resolved.

7. What are the advantages and disadvantages of proximity sensors compared to other types of sensors?

Proximity sensors have significant advantages over other types of sensors. First, they are non-contact, which means that direct contact with the object under test is not required during inspection, thus reducing the risk of wear and damage and extending service life. This characteristic makes proximity sensors ideal for detection in harsh environments such as high-speed motion or high temperatures. Proximity sensors typically provide very fast response times, which is critical for applications that require real-time feedback. Designed to be robust and capable of long-term stable operation in industrial environments and withstand the effects of vibration, shock and other external factors. Proximity sensors can also be adapted to the detection of a variety of materials, such as capacitive proximity sensors can detect almost all substances, and photoelectric proximity sensors are suitable for the detection of transparent or translucent objects. These sensors are small, easy to install, and most have standard electrical interfaces for easy integration with existing control systems. Proximity sensors are relatively inexpensive for many applications, while providing reliable performance with a good price/performance ratio.

However, proximity sensors also have some disadvantages. The most obvious is that their effective detection range is short and not suitable for long-distance detection applications. Some types of proximity sensors (such as photoelectric) are more sensitive to environmental conditions, light changes, dust, oil, etc., may affect their performance. In environments with high humidity or the presence of corrosive gases, failure of the sensor may occur if the appropriate level of protection is not provided. And some proximity sensors are particularly sensitive to specific materials, such as inductive proximity sensors are mainly used to detect metal objects, and non-metallic objects can not be effectively detected. Strong magnetic or electric fields around electronic devices can interfere with the operation of proximity sensors, especially inductive proximity sensors that use high-frequency oscillating circuits. When there are multiple objects entering the sensing area at the same time, the proximity sensor may have difficulty accurately distinguishing each object, which can lead to misjudgments.

In order to overcome these disadvantages, the selection and use of proximity sensors need to carefully consider the specific application needs. Ensure that the detection distance, environmental adaptability and target material of the selected sensor are in line with the actual working conditions. Make necessary adjustments and calibrations before installation, and take measures to reduce the impact of electromagnetic interference. By evaluating these factors in combination, you can maximize the benefits of proximity sensors while minimizing potential limitations, resulting in efficient and reliable applications.