What is a Voltage Controlled Oscillator (VCO)

2024-09-10 15:45:53 1311

Contents:

1. What is a voltage controlled oscillator

2. Basic principles

How VCO works

Key component

3. Performance indicators

Main performance parameters of VCO

4. Application field

5. Selection guide

Different types of VCO and their comparison

6. Integration and modularity

Can VCO be integrated into ics?

What is the difference between an integrated VCO and a discrete VCO?

7. Troubleshooting and maintenance

When a VCO fails, what should I start troubleshooting?

What should I pay attention to when repairing VCO?

8. Conclusion

Have you encountered problems with the selection or use of voltage controlled oscillators (VCO)? This is a common challenge in communication systems and signal processing equipment. Not understanding the VCO can cause signal instability and compromise system performance. But rest assured, because this article will be there for you.

We'll cover all the basic information you need to know about VCO in simple terms. With this guide, you will have a basic understanding of VCO and be able to cope with the various issues that may arise. So, let's get started.

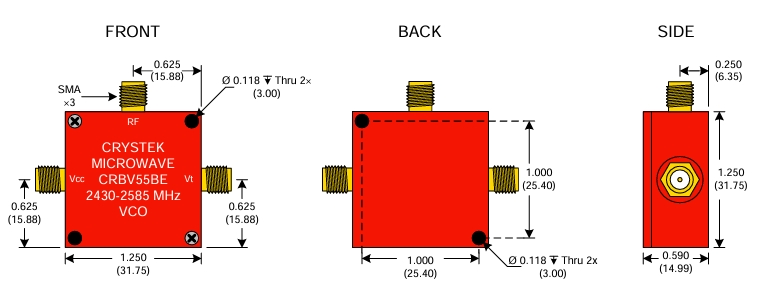

Image from: Crystek Corporation(Crystek)

1. What is a voltage controlled oscillator

A voltage controlled oscillator (VCO) is an electronic oscillator whose output signal frequency can be adjusted according to changes in the input voltage. VCO is one of the key components in many communication systems and signal processing equipment, and it has a wide range of applications in many fields, including but not limited to wireless communication, modulation and demodulation technology, frequency synthesis, and test and measurement equipment.

VCO (Voltage Controlled Oscillator) is a core component in communication and signal processing systems, and its ability to directly convert input voltage to output frequency makes it indispensable in several key technology areas. In frequency synthesis, VCO is the key to generating the desired precise frequency; In a phase-locked loop (PLL), it helps stabilize and synchronize signal frequencies; In modulation technology, VCO can realize frequency modulation and phase modulation, which is crucial for efficient data transmission. In addition, VCO is also used in radar systems to generate frequency change signals to calculate target position information. From wireless communications to test and measurement equipment, VCO is at the heart of efficient and accurate frequency control and signal processing.

2. Basic principles

How VCO works

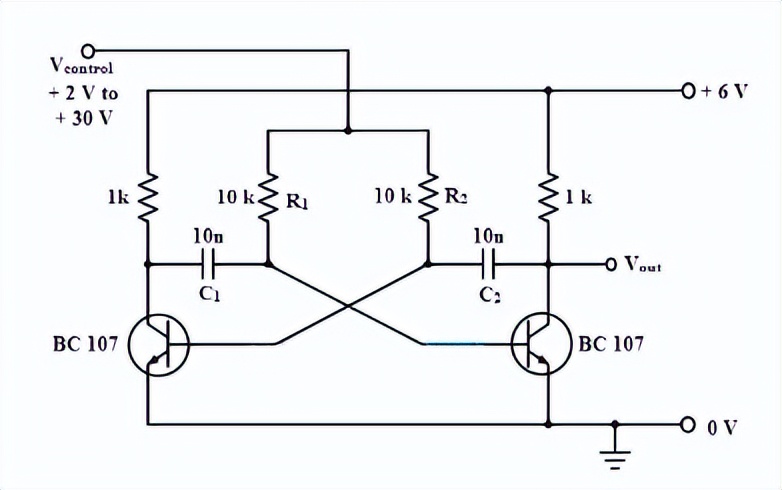

The working principle of a VCO (voltage controlled oscillator) is based on converting a change in the input voltage into a change in the frequency of the output signal. In a typical VCO design, a variable capacitor is used, which is a special diode whose capacitance value varies with the reverse bias voltage applied to it. In an oscillator circuit, these variable capacitors act as part of the oscillating loop, for example as capacitor components in LC oscillators. When the input control voltage changes, the capacitance of the variable capacitor also changes, which changes the resonant frequency of the LC oscillator, which in turn affects the frequency of the output signal.

In addition to variable capacitors, Vcos can be configured with other types of oscillators, such as RC oscillators or crystal oscillators. In these oscillators, the frequency is determined by the resistance, capacitance, or inductance in the circuit. By changing one or more of these parameters, especially the capacitance, the oscillation frequency can be changed. The change of the input voltage directly affects the state of the variable components in the circuit, thus realizing the adjustment of the frequency. When the VCO receives a specific control voltage, it produces a fixed frequency output corresponding to that voltage. If the control voltage rises, the output frequency also rises; On the contrary, if the control voltage drops, the output frequency will drop. This ability to convert a voltage signal into a frequency signal makes VCO ideal for frequency modulation applications. However, in order to ensure performance, the design of VCO also needs to consider factors such as frequency stability, phase noise and linearity.

Key component

Understanding the key components of a VCO (Voltage Controlled oscillator) can help facilitate more efficient design and application.

Here are some of the main components that make up a VCO:

-

Oscillating loop: The core of a VCO is an oscillating loop, which can be an LC (inductor-capacitance) oscillator, RC (resistance-capacitance) oscillator, or a crystal oscillator. LC oscillator is one of the most common types because it is able to provide higher frequency stability and lower phase noise. The oscillation loop determines the fundamental frequency of the VCO.

-

Amplifier/gain element: In order to maintain oscillation, an oscillator needs a gain element, such as a transistor or operational amplifier, that provides the necessary positive feedback to overcome losses in the circuit and keep the signal oscillating.

-

Feedback network: The feedback network is the part that returns a portion of the output signal to the input in order to form a closed loop with the amplifier, thus maintaining the oscillating state. This network usually consists of resistors, capacitors, and inductors.

-

Varactor diode: This is one of the key components in VCO. A varactor diode is a diode whose capacitance value is not fixed, but changes with changes in the reverse bias voltage applied to its ends. In VCO, varactor diodes are usually connected in the oscillation loop to replace or complement the role of fixed capacitors. When the input voltage changes, the capacitance of the varactor diode will change, which will change the total capacitance of the LC loop, which in turn changes the oscillation frequency. Therefore, by adjusting the input voltage, the output frequency can be controlled.

-

Buffer and isolation stage: These components are used to isolate the core part of the oscillator from the external load, prevent load changes from affecting the oscillator performance, and provide a stable output for subsequent circuit use.

The role of varactor diodes is that they provide a simple and efficient way to change the frequency of the oscillator without the need to physically replace any components. By changing the control voltage, the capacitance change of the varac diode directly leads to the change of the oscillation frequency, which is the basis of the frequency modulation of VCO.

3. Performance indicators

Main performance parameters of VCO

Understanding the main performance indicators of a VCO (Voltage controlled oscillator) is crucial to its applicability and effectiveness in a variety of applications.

Here are some of the key performance indicators and their explanations:

Frequency range: This refers to the frequency range that the VCO is capable of producing, i.e. the span between the lowest frequency and the highest frequency. The frequency range reflects the flexibility of the VCO to adapt to different application requirements.

Frequency stability: Frequency stability refers to the variation of the output frequency of the VCO under the same control voltage in a certain period of time. It is usually expressed in parts per million (ppm). The higher the frequency stability, the better the VCO can maintain the constability of its output frequency under conditions such as ambient temperature changes and power supply fluctuations.

Frequency sensitivity: Frequency sensitivity refers to the rate of change of the output frequency relative to the input control voltage, usually expressed as Hz/V. High sensitivity means that small voltage changes can cause large frequency changes, but this may increase sensitivity to noise.

Phase noise: Phase noise is an important indicator of the quality of the VCO output signal, which refers to the purity of the spectrum relative to the carrier frequency. The lower the phase noise, the higher the quality of the signal, which means less energy in the sidelobe at the off-center frequency, which is critical for many communication applications.

Modulation linearity: Modulation linearity describes the linearity of the relationship between the VCO frequency change and the input voltage change. The ideal VCO should have good linearity, that is, the frequency change is proportional to the voltage change. Nonlinearity can lead to distortion of the modulated signal.

Volt-controlled sensitivity: Volt-controlled sensitivity refers to the amount of frequency change caused by a change in unit voltage, usually expressed in MHz/V or Hz/V. It is somewhat similar to frequency sensitivity, but is more focused on describing the effect of small changes in control voltage on frequency in practical operation.

Power Supply rejection ratio (PSRR) : The PSRR is a measure of the ability of the VCO to suppress external power supply fluctuations. A higher PSRR indicates that the VCO is less sensitive to changes in the external power supply and is able to keep the frequency stable when the power supply voltage changes.

Power consumption: Power consumption refers to the power consumed by the VCO during normal operation. In battery-powered or other power-constrained applications, low-power VCO designs are ideal.

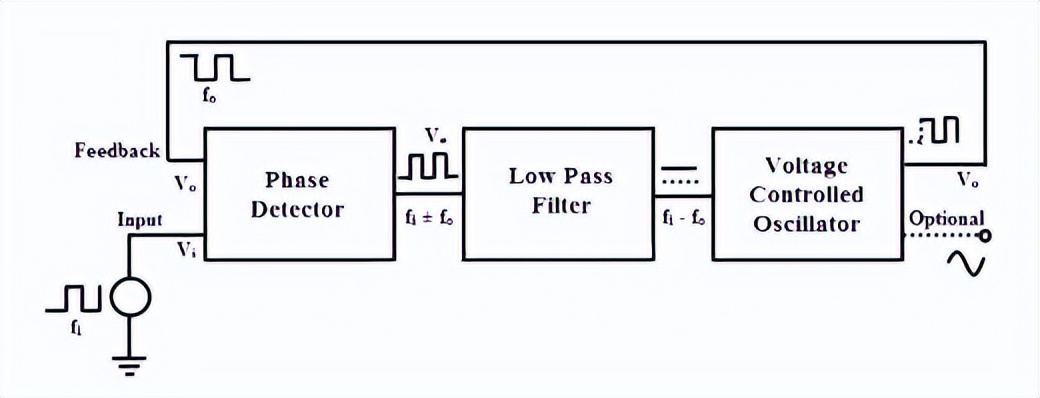

Start time and Lock time: The start time is from the time when the VCO starts to stabilize output signals. Lock time refers to the time required from loop opening to frequency locking in PLL (phase-locked loop) applications.

These performance metrics are critical when evaluating the suitability and quality of a VCO, and different application scenarios may have different priorities for these metrics. For example, in communication systems that require high spectral purity, phase noise can be one of the most important considerations.

4. Application field

VCO (Voltage controlled oscillator) has a wide range of applications in electronic systems and devices, especially in the field of wireless communication.

Here are some of the main applications of VCO in the field of electronic systems and wireless communications:

In wireless communication

Frequency synthesizer:

In wireless communication systems, a frequency synthesizer is used to generate precise transmit and receive frequencies. As one of the key components of the frequency synthesizer, the VCO can adjust the output frequency by changing the input voltage, so as to achieve the required frequency switching. This is especially important for multi-band operations, such as mobile phone systems that need to operate on different frequency bands.

Phase locked loop (PLL) :

PLL is a feedback control system used to stabilize frequency and phase. VCO is one of the core components of the PLL system. By comparing the phase difference between the input reference signal and the feedback signal generated by the VCO, the frequency of the VCO is adjusted so that the frequency and phase of the two are aligned. This mechanism is widely used in modem, satellite communication, digital TV and other fields.

Frequency modulation (FM) and Phase modulation (PM) :

During modulation, information signals are loaded onto a carrier to carry data. VCO can be used to achieve both frequency modulation (FM) and phase modulation (PM), where information signals are transmitted by changing the frequency or phase of the carrier. This modulation method is very common in broadcasting, mobile communication and other wireless communication systems.

Radar system:

In radar technology, VCO is used to generate scanning frequencies, and changes in these frequencies can be used to determine the distance and speed of a target object. Frequency agility in radar systems depends on the ability of VCO to change frequencies quickly.

Frequency hopping communication:

Frequency hopping (FH) is a technology used to improve communication security and anti-jamming ability. By rapidly changing the communication frequency, FH communication can avoid signal interception or interference. The fast frequency switching characteristics of VCO make it very suitable for frequency-hopping communication systems.

Other electronic systems

Test and measurement equipment: In the laboratory, VCO is used as a signal source to generate signals of different frequencies for testing and verification.

Clock generator: In computers and other digital systems, VCO can be used to generate clock signals that provide the basis for the timing of the system.

Music synthesizer: In electronic music devices, VCO is used to generate audio signals and is the basic building block in analog synthesizers.

5. Selection guide

Different types of VCO and their comparison

There are several types of VCO (Voltage controlled oscillator), and understanding these types can help you choose the right VCO type for your application needs.

LC Voltage Controlled Oscillator (LC-VCO)

-

Design Features: LC-VCO usually uses an LC resonant loop as a frequency determining element, in which a varactor diode is used to adjust the capacitance value of the loop, thereby changing the oscillation frequency.

-

Advantages: LC-VCO is able to provide a wide tuning range and has low phase noise. In high frequency applications, LC-VCO performs well.

-

Disadvantages: LC-VCO designs are complex, may require fine tuning for optimal performance, and have poor frequency stability compared to crystal VCO.

RC Voltage Controlled Oscillator (RC-VCO)

-

Design features: RC-VCO based on the RC network to set the oscillation frequency, by changing the resistance or capacitance value to adjust the frequency.

-

Advantages: RC-VCO is simple in design, low in cost and easy to implement.

-

Disadvantages: RC-VCO has poor frequency stability, relatively high phase noise, and limited tuning range.

Crystal Voltage Controlled Oscillator (VCXO)

-

Design Features: The VCXO uses the piezoelectric effect of the quartz crystal to control the oscillation frequency and fine-tunes the frequency by varying the voltage applied to the crystal.

-

Benefits: The VCXO provides extremely high frequency stability, making it ideal for applications that require long-term stable oscillating signals.

-

Disadvantages: The VCXO has a relatively narrow tuning range and is usually used in situations where precise frequency control is required.

Monolithic microwave integrated circuit (MMIC) VCO

-

Design Features: MMIC VCO is a VCO solution that is fully integrated on a single chip and usually includes all the necessary components for an oscillator.

-

Advantages: The compact size of the MMIC VCO makes it easy to integrate into more complex systems and can provide good performance.

-

Disadvantages: While MMIC Vcos are generally good in performance, they may not be as flexible as discrete component solutions in some cases.

Comparative summary

-

Frequency stability: Crystal voltage controlled oscillators (VCXOs) have the highest frequency stability, while RC-VCO has the worst frequency stability.

-

Phase noise: LC-VCO generally provides the lowest phase noise, while RC-VCO has relatively high phase noise.

-

Tuning range: RC-VCO and LC-VCO generally offer a wider tuning range, while VCXO has a narrower tuning range.

-

Design complexity: RC-VCO is the simplest design and the lowest cost, while LC-VCO and MMIC VCO are more complex and relatively expensive.

-

Integration: The MMIC VCO provides the highest level of integration for easy integration into the system, while the LC-VCO and RC-VCO of discrete components are slightly less integrated.

It is important to choose the right type of VCO for your specific application. For example, in applications that require extremely high frequency stability, VCXO may be preferred; In applications where broadband tuning and low phase noise are required, LC-VCO is more suitable.

6. Integration and modularity

Can VCO be integrated into ics?

Integrating VCO into ics (integrated circuits) has become a common practice in modern electronic design, especially in high frequency and radio frequency (RF) applications. This integration brings many advantages, as well as some challenges to overcome. Here are the possibilities and advantages of integrating VCO into ics:

possibility

Monolithic integration: VCO can be designed and manufactured together with other circuit elements on the same silicon chip to form a complete monolithic integrated circuit (IC). This integrated approach can significantly reduce the overall size of the circuit and improve reliability.

Hybrid integration: In some cases, it is possible to separate the VCO from partially passive components (such as inductors, capacitors, etc.) and then combine them with active ics through hybrid integration techniques to balance performance and cost.

Specialized ics: For some specific applications, such as frequency synthesizers in wireless communication systems, specialized ics can be designed to contain VCO and other related components to meet specific performance requirements.

advantage

Size reduction: Integrating a VCO into an IC can greatly reduce the size of the overall system, which is especially important for mobile devices and portable applications.

Cost effective: Integration reduces the number of external components, simplifies the manufacturing process, and reduces assembly costs. In addition, mass-produced ics typically cost less.

Improved reliability: Integration reduces the number of external connection points, reducing the chance of problems caused by poor welding or external connection failures, and improving the reliability of the overall system.

Enhanced performance: Optimizing the design within the IC can improve the performance of the VCO, such as reducing phase noise and increasing frequency stability. At the same time, the integrated design also provides better control over the signal path and reduces the impact of electromagnetic interference (EMI).

Easy integration: Integrating a VCO makes it easier for designers to combine it with other system components such as PLL (phase-locked loop), ADC/DAC (analog-to-digital/analog-to-digital converter), etc., to create highly integrated solutions.

Power reduction: The integrated design allows for optimized power management, and overall power consumption can be reduced by sharing power management resources or adopting more efficient process technologies.

Design flexibility: Integrated VCO allows designers to customize to the needs of a specific application, such as optimizing for a specific frequency range, linearity, or tuning range.

Challenge

Despite the many benefits of integrating VCO, there are some challenges, such as implementing high-performance passive components (such as high Q-value inductors) inside the IC can be difficult, and the integration design needs to address issues such as heat dissipation and possible signal interference.

In general, the integration of VCO into ics is a trend that provides compact, high-performance, low-cost solutions for a variety of modern electronic systems, especially in areas such as wireless communications, radar technology, and test instrumentation.

What is the difference between an integrated VCO and a discrete VCO?

There are obvious differences between integrated VCO (voltage controlled oscillator) and discrete VCO in design, performance, application and manufacture.

INFINITECH compares the two types of VCO in detail below:

Design complexity

-

Integrated VCO:

-

Integrated VCO is the integration of all the necessary components on a semiconductor chip, including active devices (such as transistors) and passive components (such as capacitors and inductors). This integrated design usually requires advanced process technology to achieve.

-

When designing integrated VCO, it is necessary to consider the parasitic effects in the chip, such as parasitic capacitance, resistance, etc., which may affect the performance of the oscillator.

-

-

Separate VCO:

-

Discrete VCO consists of individual components, such as discrete transistors, resistors, capacitors, and inductors. These components are connected by a printed circuit board (PCB).

-

Discrete design is relatively simple because the components can be selected and optimized independently, but it also means that the designer needs more space to place these components.

-

Performance characteristics

-

Frequency stability:

-

The frequency stability of an integrated VCO may be affected by changes in chip manufacturing processes and temperature. However, modern integration technologies have greatly improved this aspect.

-

Discrete VCO is generally able to provide higher frequency stability due to the use of high-quality discrete components.

-

-

Phase noise:

-

Integrated VCO may not perform as well as discrete VCO in terms of phase noise, especially in high-frequency applications. However, by optimizing the design and using advanced processes, the phase noise of the integrated VCO has been greatly improved.

-

Discrete VCO can achieve low phase noise by carefully selecting and matching components.

-

-

Tuning range:

-

The tuning range of an integrated VCO may be limited by the availability of varactor diodes within the chip, but modern designs are often able to provide a wide tuning range.

-

The design flexibility of discrete VCO is greater, and the desired tuning range can be achieved by selecting different components.

-

Cost and size

-

Cost:

-

Integrated VCO usually has lower manufacturing costs due to the reduced number of external components and simplified assembly process.

-

Discrete VCO may be relatively costly due to the need for more manual assembly and testing.

-

-

Size:

-

The integrated VCO offers significant miniaturization benefits and is particularly suitable for space-constrained applications, such as mobile devices.

-

Discrete Vcos take up more space, but because the components can be distributed, they sometimes have better performance in terms of thermal management and electromagnetic compatibility.

-

Application field

-

Integrated VCO:

-

It is more suitable for applications requiring compact, low power consumption and high integration, such as mobile devices such as smartphones and tablets, as well as frequency synthesizers in modern communication systems.

-

Suitable for products requiring mass production and standardization.

-

-

Separate VCO:

-

It is more common in applications that require high performance and highly customized design, such as high-end communications equipment, specialized test instruments, and some special-purpose radar systems.

-

Suitable for applications that have strict performance requirements and are willing to accept higher costs and larger volumes.

-

Manufacturing and testing

-

Integrated VCO:

-

The production process is highly automated and can be mass-produced using semiconductor manufacturing technology.

-

The testing process is often closely integrated with chip manufacturing and may require specialized testing equipment.

-

-

Separate VCO:

-

More manual assembly is required in the production process, especially for customized components in high-end applications.

-

The testing process can be more complex because it needs to be checked and adjusted on a component-by-component basis.

-

Combined with the above comparison, there are advantages and disadvantages of integrated VCO and discrete VCO, and the choice of which one depends on the requirements of the specific application, budget constraints, and design goals.

7. Troubleshooting and maintenance

When a VCO fails, what should I start troubleshooting?

When the VCO (voltage controlled oscillator) fails, it can be investigated from the following aspects:

a. Check the input voltage

-

Control voltage: Verify that the control voltage input to the VCO is correct. Use a multimeter to check whether the actual input voltage is consistent with the expected value and does not exceed the operating voltage range of the VCO.

-

Power supply voltage: Check whether the power supply voltage of the VCO is stable and meets the specifications. Unstable or incorrect supply voltages may cause the VCO to fail to function properly.

b. Output frequency verification

-

Frequency measurement: Use a frequency counter or oscilloscope to measure the output frequency of the VCO to confirm that it meets expectations. If the frequency is incorrect, the relevant frequency control element needs to be further checked.

-

Frequency stability: Observe the stability of the output frequency over a period of time and whether there is drift. Unstable frequencies may indicate power supply fluctuations, temperature changes, or other factors.

c. Check components

-

Varactor diode: Check the varactor diode for damage or performance degradation. Varactor diode is the key variable component in VCO, and its failure will lead to the failure of frequency control.

-

Oscillating circuit components: Check other components in the oscillating circuit (such as inductors and capacitors) for damage or aging. The failure of these components will directly affect the performance of the oscillator.

d. Peripheral circuit check

-

Feedback network: Check whether the feedback network around the VCO is normal, including resistors, capacitors and other components are installed according to the design requirements and are not damaged.

-

Amplifier and buffer: Ensure that the amplifier and buffer circuit is working properly and there is no short circuit or open circuit.

e. Temperature and environmental factors

-

Temperature impact: Check whether the operating temperature of the VCO is within the specified range. Too high or too low a temperature may affect the performance of the VCO.

-

Electromagnetic interference (EMI) : Ensure that there are no strong electromagnetic interference sources around the VCO to prevent interference from affecting the normal operation of the VCO.

f. Grounding and shielding

-

Grounding: Check that the ground cable of the VCO is correctly and firmly connected. Poor grounding can cause signal distortion and instability.

-

Shielding effect: Confirm whether the VCO has sufficient shielding measures to prevent interference from external signals.

g. Design and specification review

-

Design drawings: Check whether the actual assembly meets the design requirements against the design drawings and specifications.

-

Parameter review: Re-review the VCO parameter Settings, including frequency range, frequency stability, etc., to ensure that all Settings are correct.

h. Software control

-

If the VCO is controlled by software, check that the control software is working properly, including drivers, firmware updates, etc.

i. Fault isolation

-

Step isolation method: Try to disconnect the VCO from the peripheral circuit and test each part one by one to determine the source of the fault.

-

Replacement method: Replace the suspected faulty component with a known good component to see if the problem can be solved.

By performing the preceding steps, you can systematically troubleshoot possible VCO faults and locate faults.

What should I pay attention to when repairing VCO?

Safety is always a primary consideration when servicing VCO or other electronic equipment.

Here are some safety matters and other points to pay attention to during maintenance:

Safety matters

Disconnect power: Before starting any repair work, ensure that the device has been removed from the electrical outlet to avoid the risk of electric shock. For devices with capacitors, wait until the capacitors are fully discharged before touching them.

Personal Protective Equipment (PPE) : Use insulated gloves to protect your hands from electric shocks. Wear goggles to prevent eye damage, especially when working with sharp or small parts. When handling chemicals, such as flux, wear a mask to avoid inhaling harmful gases.

Anti-static measures: Wear an anti-static wristband or stand on an anti-static mat to reduce the damage of electrostatic discharge to sensitive electronic components. Make sure your workbench and tools are anti-static.

Good ventilation: When welding or using any chemicals that may produce harmful gases, ensure that the working area is well ventilated, and it is best to operate in a place with good ventilation.

Tool use: Use the right tools for repair work to avoid additional damage caused by the use of inappropriate tools. Tools should be kept clean and checked regularly to ensure they are in good condition.

Avoid short circuit: During disassembly or assembly, be careful to prevent short circuit caused by metal tools or foreign objects.

Maintenance point

Record the status quo: Take pictures or draw a sketch before disassembly to record the wiring situation and component location inside the device for correct assembly after maintenance.

Orderly disassembly: Disassemble the device in a certain order, and properly store screws and other small parts to avoid loss. Use a marking paper or plastic bag to store the parts in different parts and mark them clearly.

Cleaning and maintenance: During the repair process, properly clean the inside of the equipment to remove dust and impurities, but make sure that the cleaning tools used will not damage the circuit. Use a soft brush or hair dryer to gently remove dust.

Inspect components: Carefully inspect all components for physical damage or signs of aging, such as capacitance bulge, resistance burning, etc. Use a multimeter to check the electrical characteristics of components such as resistors, capacitors, and diodes to ensure that they work properly.

Replace damaged parts: When replacing damaged or poorly performing components, ensure that the new part has the same specifications as the original part. Use appropriate welding tools and techniques to avoid welding defects or short circuits.

Test and verification: After the reassembly is completed, a preliminary functional test is carried out to confirm that the equipment can start normally. Use professional instruments such as frequency counters, oscilloscopes, etc. for comprehensive testing to verify that the performance after maintenance meets the standard.

Documentation: Records the findings and actions taken during maintenance, as well as the final test results, to facilitate future maintenance or troubleshooting.

Professional consultation: If you encounter problems that can not be solved by yourself, seek the help of professionals in time to avoid blind operation leading to greater losses.

Following the above safety matters and maintenance points can effectively complete the maintenance work of VCO, while ensuring the personal safety of maintenance personnel. Always put safety first when carrying out any repair activity and operate strictly in accordance with the guidelines and industry standards provided by the manufacturer.

8. Conclusion

In short, by understanding the basic principle of VCO, key performance indicators and the characteristics of different types of VCO, we can better choose and apply VCO to meet the needs of different scenarios. Whether from the perspective of integration and modularity, or from the practice of troubleshooting and maintenance, the knowledge of VCO can help us improve the reliability and efficiency of the system. I hope this article can provide you with practical information to help you use VCO technology more effectively in your practical work.