What is the difference between a signal isolator and a safety fence?

2024-08-05 11:25:35 1134

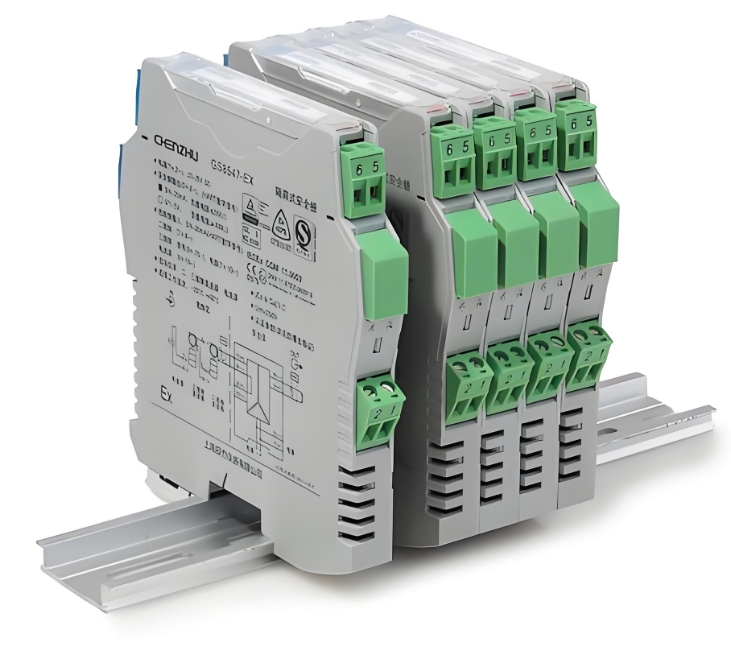

In industrial automation, signal isolators and safety gates are two common important devices used to protect systems from interference, improve measurement accuracy, and ensure personnel safety. While they are used interchangeably in some applications, there are significant differences between the two. Here, INFINITECH will explain signal isolators and safety gates and the difference between them.

I. Overview of signal isolators

Definition and function

A signal isolator is an electronic device primarily used to convert an input signal from a sensor or controller into another output signal format while providing electrical isolation. This isolation prevents power supply voltage fluctuations, electromagnetic interference (EMI), and ground loop currents from affecting signal transmission, thereby improving signal accuracy and reliability.

peculiarity

-

Electrical isolation: Electrical isolation between input, output and power supply is achieved through technologies such as photocouplers or transformers to prevent the formation of current loops, thus avoiding interference or damage to downstream equipment.

-

Signal conversion: One type of signal can be converted to another type, such as converting a current signal to a voltage signal, or vice versa. Support for different types of signal input and output (e.g. 4-20mA, 0-10V, etc.)

-

Anti-interference: Reduce the impact of noise and interference.

-

Flexibility: Suitable for a variety of signal types and interfaces.

-

Noise suppression: Reduce electromagnetic interference (EMI) and radio frequency interference (RFI) during long-distance transmission and improve signal quality.

-

Ground loop elimination: Eliminate the ground loop problem caused by the ground potential difference between different devices.

-

Protection function: Provides overvoltage protection and short circuit protection to protect the back end control system from damage.

-

Signal amplification and adjustment: Amplify or adjust the signal as needed to ensure that the signal is suitable for subsequent processing.

Working principle

The working principle of the signal isolator is based on electrical isolation technologies such as photoelectric coupling and magnetic coupling. Photocoupling technology uses light-emitting diode (LED) and photosensitive transistor or photoresistor, when the input signal changes, the brightness of the LED changes, and then affects the on-state of the photosensitive element, to achieve the isolated transmission of the signal. The magnetic coupling generates the corresponding current change in the secondary coil through the magnetic field generated by the current change in the primary coil, so as to achieve the isolated transmission of signals. In addition, the signal isolator also performs signal modulation conversion through semiconductor devices, and then realizes isolation conversion through photoelectric or magnetic sensing devices, and finally demodulated back to the original signal. These isolation technologies ensure accurate signal transmission and effectively prevent ground loop current interference, electromagnetic interference (EMI) and radio frequency interference (RFI), protecting the control system from high noise environments. At the same time, the signal isolator can also perform signal conversion, amplification and regulation, as well as provide overvoltage and short circuit protection to ensure the integrity and accuracy of the signal during long-distance transmission.

The function of the signal isolator

The primary role of the signal isolator is to provide electrical isolation to enhance the stability and reliability of the system. It realizes electrical isolation between input, output and power supply through photoelectric coupling or magnetic coupling technology to prevent ground loop current interference and reduce the impact of electromagnetic interference (EMI) and radio frequency interference (RFI). In addition, the signal isolator can also perform signal conversion, support the exchange of voltage signals and current signals, and can amplify and adjust the signal to ensure that the signal strength meets the requirements of subsequent equipment. To further improve the safety of the system, the signal isolator also provides overvoltage protection and short circuit protection to prevent excessive voltage or short circuit damage to downstream equipment. At the same time, it can also convert an input signal into multiple isolated output signals, which is convenient for signal distribution. In summary, the signal isolator can not only improve the quality of the signal, but also effectively protect the system from external interference, which plays a vital role in the industrial automation system.

Application scenario of the signal isolator

In chemical plants, signal isolators are used to protect the control system from the harsh environment on site and ensure the accurate transmission of signals. Used to connect various sensors, transmitters and other field equipment, such as temperature sensors, pressure transmitters, etc.

In oil refineries, signal isolators are used to connect equipment such as thermometers and flow meters to the control room to ensure that signals are protected from electromagnetic interference. Used to eliminate ground loop problems and prevent signal distortion.

In power systems, signal isolators are used to connect generators, transformers and other power equipment monitoring systems to ensure the accuracy of signal transmission. Used for signal isolation in high voltage environments to protect the control system from high voltages.

In automotive production lines, signal isolators are used to connect various sensors and actuators to ensure reliable signal transmission. Used to improve the efficiency and reliability of the production line.

In pharmaceutical factories, signal isolators are used to connect various analytical instruments, reactors and other equipment to ensure the accuracy of data acquisition. Used to prevent signal interference and ensure precise control during production.

In food processing lines, signal isolators are used to connect temperature, humidity and other sensors to ensure precise control during production. Used to protect the control system from humid environments.

In the environmental monitoring system, the signal isolator is used to connect various weather stations, water quality monitoring equipment, etc., to ensure that signal transmission is not interfered with by external factors. Used to improve data reliability and accuracy.

In building automation systems, signal isolators are used to connect sensors and actuators in various building management systems, such as air conditioning systems, lighting systems, etc. Improve system stability and reduce maintenance costs.

In the railway signal system, the signal isolator is used to connect the track signal, switch controller and other equipment to ensure the accuracy of signal transmission. To improve the safety of the transportation system.

In agricultural automation systems, signal isolators are used to connect irrigation systems, greenhouse control systems, etc., to ensure accurate signal transmission. To improve the efficiency and sustainability of agricultural production.

Second, security grid overview

definition

A safety gate is a specially designed interface module that protects essential safety circuits from non-essential safety circuits and ensures that equipment used in hazardous areas will not cause an explosion or fire. It not only provides electrical isolation of the signal, but also limits current and voltage to meet specific safety standards.

peculiarity

-

Electrical isolation and current limiting: through built-in resistors and diodes and other components.

-

Intrinsic safety: ensures that energy sufficient to ignite combustible gas is not generated even under failure conditions.

-

Compliance: Meets international safety standards (e.g. IEC 60079 series).

-

Signal regulation: Support signal conversion and regulation.

The role of the safety grid

A safety fence is an electronic device used in the field of industrial automation to protect the connection between field instruments and control systems, especially in the presence of explosive gases or dust. Its main functions include providing electrical isolation to prevent hazardous energy from flowing from the control system to the hazardous area, thereby avoiding situations that may cause an explosion; To ensure that instruments entering hazardous areas do not become ignition sources due to excessive energy by limiting the current and voltage passing through; Converts and adjusts the signal to ensure its accuracy and completeness, and may have signal amplification capabilities; Equipped with a fault detection mechanism to cut off the signal or power supply in case of abnormal conditions to protect the entire system; It also provides protection against lightning strikes and surges to ensure the stable operation of the system. In short, safety grids are an important part of ensuring the safe operation of these systems in hazardous environments.

Common type

-

Intrinsic safety gate: Specially used in intrinsic safety circuits to ensure that the circuit will not become an ignition source even in a fault state.

-

Zener safety gate: The use of Zener diodes to limit voltage and current is one of the most common types of safety gate.

-

Isolated safety gate: Provides electrical isolation while limiting energy for applications requiring higher levels of isolation.

-

Intelligent safety grid: With a higher level of signal processing and diagnostic capabilities, it can be integrated with modern control systems.

Apply

In oil refineries, chemical plants and other sites, safety grids are used to protect the connection between the field instrument and the control room, ensuring safe transmission of signals even in harsh conditions. They are used to connect sensors, transmitters and other field equipment to ensure that the signal transmission between these devices and the control system does not cause sparks or overheating, thereby avoiding possible explosive accidents.

In pharmaceutical plants, safety grids are used to ensure secure communication between production equipment and control systems, especially on production lines involving flammable solvents and chemicals.

In food processing plants, especially in areas where explosive dust can be generated, such as handling flour, safety barriers are used to protect the connection between the field equipment and the central control system.

In underground mines and open pit mines, safety booms are used to protect communication between field equipment and ground control rooms, ensuring safe operation in environments where gas or explosive dust may be present.

On oil RIGS and ships transporting chemicals, safety barriers are used to protect the connection between the control system and field equipment, ensuring safe operation in these hazardous environments.

In power plants and substations, safety grids are used to protect connections between field equipment and control systems, especially in facilities involving flammable gases and liquids.

In paint and coating manufacturing plants, safety grids are used to ensure secure communication between field equipment and control systems, especially on production lines involving flammable solvents.

At environmental monitoring stations, especially those located in potentially explosive environments, safety grids are used to protect communication between on-site monitoring equipment and remote control centers.

Three, the main difference between the signal isolator and the safety gate

Different purpose

-

The main purpose of signal isolators is to improve signal quality and reduce noise and interference.

-

Safety grids focus on protecting equipment and personnel from hazardous environments and ensuring the intrinsic safety of the system.

Different design principles

-

Signal isolators realize signal isolation through optocouplers or magnetic couplers and other technologies.

-

In addition to signal isolation, the safety gate also needs to ensure the safe operation of the system through the design of current limiting and voltage limiting.

Standards are different from certification

-

Signal isolators are typically required to meet general industry standards such as EMC and temperature range requirements.

-

Safety grids are subject to more stringent safety standards, such as those in the IEC 60079 series.

Different use occasions

-

Signal isolators are suitable for most industrial applications, especially for the needs of signal quality and stability.

-

Safety grids are specifically designed to deal with signal transmission in explosive gas environments.

Although the signal isolator and the safety gate are similar in some aspects, their design purposes, working principles and application scenarios are clearly different. Choosing the right equipment is critical to ensuring the reliability and safety of your system.