Circular connectors: Features, types, application scenarios, and Purchase guide

2024-06-25 10:11:45 779

As a vital link in electronic systems, circular connectors have become an indispensable choice in many industries due to their unique design and superior performance. From aerospace to medical equipment, from military applications to daily communications, circular connectors are everywhere, they not only ensure the stable transmission of power, signals and data in complex environments, but also reflect the essence of scientific and industrial progress. In this article, INFINITECH will focus on circular connectors, analyze their construction, characteristics, application scenarios and purchase guidelines, and introduce the contributions of well-known global brands. Follow our steps to experience the charm of circular connectors and witness how they play a key role in connecting the world, supporting the efficient operation of modern society and technological innovation.

Main points of this article:

> What is a circular connector

> What types of circular connectors are available

> Application scenarios for circular connectors

> How to choose the right circular connector

> Which brands offer high quality circular connectors

What is a circular connector?

A circular connector is an electronic connector that has a cylindrical basic structure and a circular mating surface, which makes them physically different from rectangular or other shaped connectors. They are commonly used for interconnection between devices and belong to Category 5 in the interconnection classification.

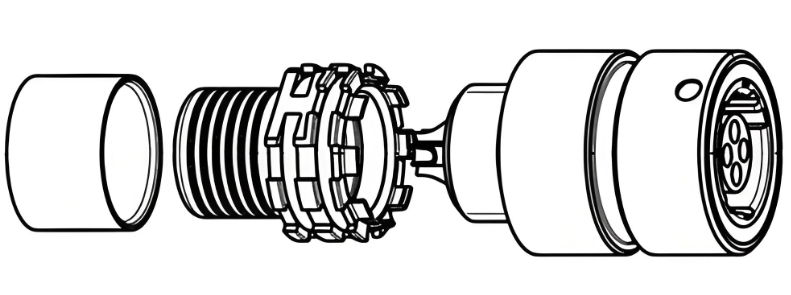

The main components of the circular connector include:

-

Plug: This is the part of the connector, usually fixed to one end of the device, that contains the center lead, housing, contacts, and other components.

-

Socket: This is another part of the connector, usually fixed on the other end of the device, corresponding to the structure of the plug, composed of pins, contacts and other parts.

These connectors are capable of transmitting power, signals, or data, and because of their cylindrical construction, they have natural robustness and a high strength-to-weight ratio, which makes them particularly useful in a variety of harsh environments and high-vibration applications, such as in industrial, aerospace, military, and medical devices.

Advantages of circular connectors include:

-

Robustness: The cylindrical structure provides additional mechanical strength.

-

Water and dust resistance: Many circular connectors have a sealing function to prevent water and dust from entering.

-

Easy to use: They are usually designed to be easy to connect and disconnect.

-

Reliability: Stable connections in high vibration environments.

Disadvantages may include:

-

Cost: Circular connectors may cost more than some standard rectangular connectors.

-

Size: In space-constrained applications, the volume of a circular connector may become a consideration.

What are the types of circular connectors

Circular connectors have many types in different industries and applications because of their wide range of uses and adaptability. Here are some of the main categories:

-

Classification by function:

-

Power connector: mainly used to transmit power, can handle large current and voltage.

-

Signal connector: Used to transmit electrical signals, including analog and digital signals.

-

Data connector: For high-speed data transmission, may include differential pair design to support high-speed data rates.

-

Fiber optic connectors: Used for optical signal transmission, common in high-bandwidth networks and telecommunications applications.

-

Air connectors: Used to transmit gas or liquid media, common in medical devices and industrial controls.

-

-

By connection type:

-

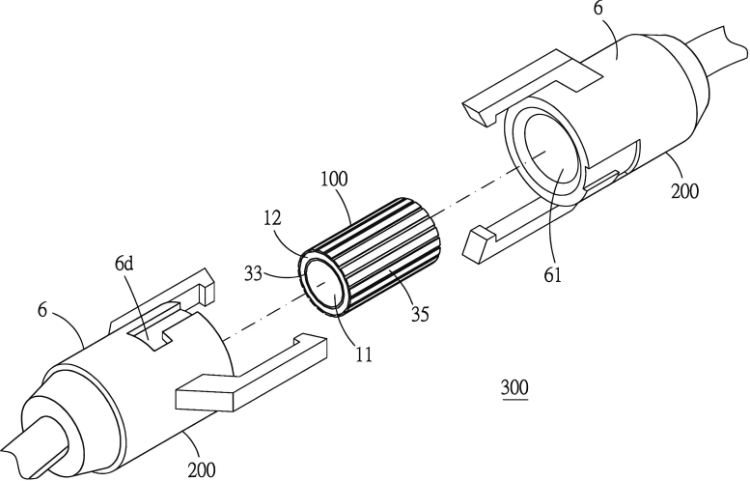

Threaded connectors: Connected by rotary locking, providing stable mechanical and electrical connections for use in harsh environments.

-

Quick-plug connectors: Connect with a simple insertion and locking mechanism for quick connection and disconnection.

-

Bayonet connector: Use bayonet locking, connection and disconnection quickly, suitable for frequent insertion and removal occasions.

-

Pluggable connectors: Usually used for low-frequency signal and power transmission, they are connected by direct insertion and withdrawal.

-

Latch connectors: Use a latch mechanism for locking to provide additional security.

-

Quick-plug connectors: Designed for quick connection and disconnection, commonly found in field-replaceable modules or devices.

-

-

Classified by special function:

-

Shielded connector: With a metal shield to reduce electromagnetic interference (EMI) and radio frequency interference (RFI), suitable for high-frequency signal transmission.

-

Sealed connector: with a sealing ring or gasket to prevent water, dust or harmful gases from entering, suitable for outdoor or harsh environments.

-

-

By brand and standard:

-

MIL-C-5015: United States military standard circular connector, widely used in the military and aviation fields.

-

MIL-C-26482: Another U.S. Army standard connector for use in high vibration and shock environments.

-

ODU: A European brand that offers a wide range of high-performance circular connectors, including the MEDI and MINI-SNAP series, for medical and industrial equipment.

-

Lemo: A Swiss brand known for its high quality and precision circular connectors, widely used in the broadcast and television, test and measurement and medical industries.

-

-

Classification by physical characteristics:

-

Right Angle and corner type: according to the connector geometry and installation direction.

-

Pinhead circular navigation and pinhole circular navigation: refers to the type of contact in the connector.

-

-

By terminal type:

-

Welded end: The contact end is designed to be welded to the circuit board.

-

Crimping terminal: Secure the wire to the contact by crimping tool.

-

Printed plastic terminal: directly combined with plastic substrate or printed circuit board.

-

Choosing the right circular connector type depends on the specific application needs, including signal type, environmental conditions, connection frequency, cost budget and other factors.

How do they work

The working principle of the circular connector is based on the electrical contact theory, and its core function is to build a solid electrical channel to achieve the effective transmission of power, signals or data. When working, the plug of the connector is precisely connected to the socket, and the contacts on the plug - such as pins or contacts - are in close contact with the corresponding contacts inside the socket, usually a sleeve or spring sheet. These contacts are made of high-quality conductive materials, such as copper alloys or gold-plated copper alloys, designed to ensure low impedance connections while resisting corrosion risks.

Well-designed contacts ensure sufficient contact force to maintain a reliable electrical connection, even in a vibrating environment. Once the physical connection is established, whether it is an analog signal, a digital signal, a data stream or a power supply, it can be passed between the two connectors without hindrance. Connectors often integrate multiple independent contacts, each carrying a different signal or circuit. For high frequency signals or sensitive circuits, connectors may also have built-in shielding to effectively protect against electromagnetic interference (EMI) and radio frequency interference (RFI), with a metal housing surrounding the signal path for enhanced protection.

In specific use cases, circular connectors are equipped with sealing devices, such as seals or gaskets, to effectively insulate moisture, dust and other contaminants, ensuring performance stability in harsh conditions. In order to strengthen the safety and firmness of the connection, the connector has a permanent locking mechanism, including threads, clasps or spring locks, to prevent unexpected disconnection. The user can easily split the plug and socket with the help of the unlocking mechanism to achieve electrical path disconnection. The circular connector design focuses on easy disassembly, facilitating daily inspection, cleaning and replacement of damaged parts, thereby improving the maintenance efficiency and service life of the system.

Application scenarios for circular connectors

Circular connectors are rugged, waterproof, dust-proof, vibration-resistant, and easy to install, making them suitable for a variety of applications, especially where high-reliability connections are required. The following are some common application areas of circular connectors:

Aerospace: In aircraft, satellites, rockets and other aircraft and spacecraft, circular connectors are used to connect various electronic devices, sensors and control systems that can withstand extreme temperature changes, high vibration and shock.

Military field: Circular connectors are widely used in a variety of military equipment, such as electronic warfare equipment, radar systems, satellite communication equipment, etc., they need to maintain a high degree of reliability and protection performance in harsh combat environments.

Transportation and industry: Automobiles, railway vehicles, industrial automation equipment, etc., all use circular connectors for data transmission, signal transmission, and power supply, especially where vibration and harsh environmental conditions need to be tolerated.

Communication field: data centers, network equipment, telephone networks, security monitoring systems, etc., use circular connectors for signal and data transmission, such as RJ45 circular connectors in local area networks and telephone networks.

Medical devices: Circular connectors are used in medical devices to ensure a high degree of safety and reliability, and are suitable for a variety of medical instruments and devices that require precise signal transmission and power management.

Security monitoring: security equipment such as surveillance cameras and network video recorders use circular connectors for video signal transmission and data communication.

Machine room equipment: Servers, switches, routers, firewalls and other equipment in the machine room use circular connectors to achieve efficient data transmission and interconnection between devices.

Fieldbus system: In industrial automation, circular connectors (such as the M12 series) are suitable for signal and data transmission of process control and field equipment, and the protection level can reach IP67 or more, which is suitable for harsh industrial environments.

Sensor and actuator connection: Circular connectors are used to connect various sensors and actuators, such as temperature sensors, pressure sensors, motor drives, etc., to ensure accurate data acquisition and control signal transmission.

Other fields: Circular connectors are also used in home entertainment systems, scientific research equipment, laboratory instruments, test and measurement equipment and other fields.

How to choose the right circular connector

Selecting the right circular connector requires consideration of several aspects to ensure that the connector selected meets all the requirements of a particular application.

In terms of application requirements:

Electrical characteristics: Consider the rated voltage, current carrying capacity, contact resistance, insulation resistance and voltage resistance of the connector. Make sure the connector can handle the expected electrical load.

Signal type: Verify that the connector is suitable for transmitting analog signals, digital signals, high-speed data, or power.

Connection type: Determine whether you want a power connection, signal connection, or data connection.

In terms of physical specifications:

Size and shape: Select a connector that matches the size and shape of the device interface.

Port type: Select the correct port type based on the application, for example, M6, M8, and M12.

Number of pins: Select the correct number of pins based on the number and type of signals that need to be transmitted.

Right Angle or straight type: Consider the installation location and space constraints, choose a right Angle or straight type connector.

Environmental requirements:

Protection level: Consider the IP level of the connector to ensure normal operation in damp, dust, oil and other environments.

Temperature range: Ensure that the connector can operate stably within the expected temperature range.

Corrosion protection and chemical stability: If the connector will be exposed to a corrosive or chemical environment, select the appropriate materials and coatings.

Mechanical properties:

Durability: Evaluate the durability of the connector, taking into account the expected number of insertions and service life.

Connection mode: Select the connection mode suitable for the application, such as threaded connection, bayonet connection, quick lock connection, etc.

Seismic and shock resistance: Select connectors with appropriate mechanical stability in vibration and shock environments.

Electrical connection:

Crimp, weld or screw fastening: Select the most suitable wiring method according to the application and maintenance requirements.

Shielding requirements:

If the application needs to reduce electromagnetic interference (EMI) or radio frequency interference (RFI), choose a connector with shielding.

Cost considerations:

Compare the cost effectiveness of different connectors while meeting performance requirements.

Supplier reputation:

Choose well-known and reputable suppliers to ensure product quality and after-sales service.

Compliance and Certification:

Verify that connectors comply with relevant industry standards and safety certifications, such as CE, UL, RoHS, etc.

Future scalability:

Take into account possible future demand changes, choose a connector with some flexibility and scalability.

Tip: In the actual selection process, you may need to make trade-offs between the above factors. It is recommended to consult the connector manufacturer or distributor's technical support team for application-specific professional advice before making a final selection.

Which brands offer high quality circular connectors?

There are many brands that offer high quality circular connectors in the global market, here are some well-known manufacturers:

-

3M - 3M offers a wide range of interconnect products, including circular connectors, for a variety of industrial and commercial applications.

-

Amphenol Corporation - Amphenol and its subsidiaries offer a broad range of interconnect products, including circular connectors, for multiple industries from aerospace to automotive.

-

Amphenol Aerospace Operations - Specializes in interconnect solutions for the aerospace and defense industry.

-

Amphenol Air LB - provides connectors for the aviation and commercial aviation markets.

-

Amphenol Alden Products Company - focuses on interconnect products for industrial and heavy equipment applications.

-

Amphenol Audio - Interconnect solutions for the audio and entertainment industries.

-

Amphenol ICC (Commercial Products) - Connector and interconnect products for business and communication applications.

-

Amphenol Industrial Operations - Interconnect solutions for the industrial market.

-

Amphenol Limited - Interconnect products serving the European market.

-

Amphenol LTW - Interconnect solutions for the industrial and transportation markets.

-

Amphenol NEXUS Technologies - Provides interconnect products for rail and rail transit.

-

Amphenol Onanon - Connectors specifically designed for heavy equipment and agricultural machinery.

-

Amphenol PCD - High-performance interconnect systems, including circular connectors, for extreme environments.

-

Amphenol Sine Systems Corp. - Focused on power and signal interconnect solutions.

-

Amphenol Socapex - High performance connectors for broadcasting, lighting and military applications.

-

Amphenol Tuchel Industrial - Industrial circular connectors and cable assemblies.

-

Anderson Power Products, Inc. - Specializes in power connectors, including round and rectangular designs.

-

Assmann WSW Components - Provides connectors for data and signal transmission.

-

ATTEND Technology - focuses on the development and production of electronic connectors.

-

Balluff - Sensors and connectors for industrial automation.

-

Banner Engineering Corporation - Provides sensors, vision systems, wireless networking products and connectors.

-

BERNIER Connect - High quality connector and cable solutions.

-

Bulgin - Durable and reliable industrial and waterproof connectors.

-

Carlo Gavazzi Inc. - Solutions provider for industrial automation and energy management.

-

Chogori Technologies Inc. - Supplier of electronic components and interconnect systems.

-

Cinch Connectivity Solutions - High performance interconnect products including circular connectors.

-

CLIFF Electronic Components Ltd - Provides connectors and components for the broadcast and test industries.

-

CNC Tech - focuses on the manufacture of connectors and cable assemblies.

-

Conec - German company offering circular connectors and industrial connectors.

-

Conxall/Switchcraft - Provides connectors for the military, aerospace and industrial markets.

-

CUI Devices - Offers a wide range of electronic components, including connectors.

-

Finecables - Supplier of cables and connectors.

These brands are respected by the industry for their product reliability, innovation and customer service. When selecting a connector, in addition to considering the brand reputation, the performance, specifications, cost and availability of the connector should also be evaluated according to the specific application needs. Manufacturer or distributor INFINITECH can be contacted for more detailed technical information and sample testing before deciding.