Test maintenance practical guide: Teach you how to correctly replace the resistor

2024-06-13 14:26:48 419

Building on the previous article "Resistor Encyclopedia: Types, power calculations, application examples, and color ring decoding";, we will continue to explore the topic of resistors, covering their common fault types, detection methods, selection guidelines, and correct steps to replace resistors, and further provide a series of practical knowledge and tips.

Resistor fault and detection method

As a basic and widely used component in electronic circuits, resistors may encounter many kinds of faults. Here is an overview of some common faults and their detection methods:

Common fault types

-

Resistance change: This is one of the most common failures, which may be due to excessive temperature, voltage, or circuit anomalies that cause the resistance value to deviate from its nominal value, as the resistance value becomes larger or smaller.

-

Open circuit: means that the resistance is broken inside, manifested as the resistance value between the two ends of the resistance tends to infinity, and the circuit is blocked.

-

Poor internal contact: May lead to noise, noise or intermittent malfunction in the circuit, especially in potentiometers.

-

Potentiometer switch structural damage: the potentiometer built-in switch part may have mechanical damage, affecting its normal switching or adjustment function.

Detection method

Fixed resistor

-

Use the resistance of the multimeter for detection, select the appropriate range, so that the measurement value falls in the middle part of the dial scale (about 20% to 80%) to improve the measurement accuracy.

-

Connect the pen directly to both ends of the resistor, read the displayed value and compare it with the nominal resistance value.

potentiometer

-

Manually rotate the potentiometer handle to check whether it is smooth and free of stalls, and whether the switch is flexible.

-

Use a multimeter to measure both ends (fixed ends) of the potentiometer to determine the overall resistance.

-

Turn the handle, and gradually measure the change in resistance value between the active end and the fixed end, which should be smooth and continuous, without skipping or discontinuity.

Fuse the resistor

-

If there are burn marks on the resistance surface, it indicates overload.

-

For a normal fuse resistor, remove it from the circuit and use a multimeter to check whether the circuit is open.

Other notes

-

In the measurement of high resistance value resistance, avoid the parallel effect of human resistance, especially the use of pointer multimeter.

-

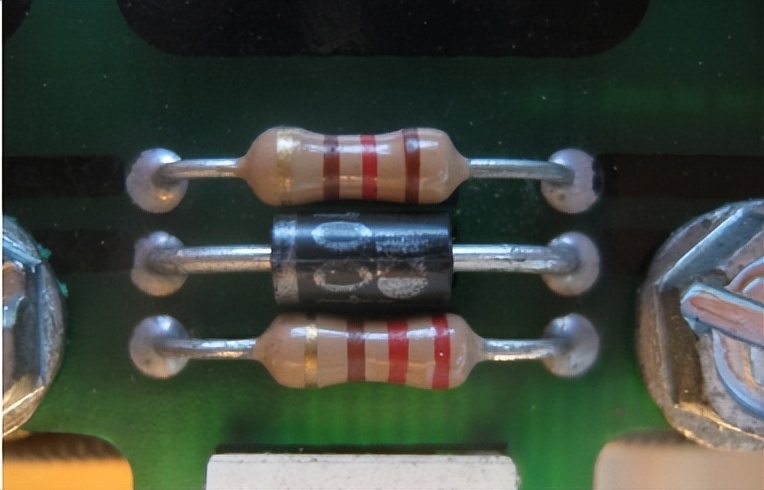

For color ring resistance, etc., it is also necessary to identify its color ring code to determine its nominal value, and then compare it with the measured value.

-

Before taking any measurements, ensure that the circuit power supply is disconnected to avoid damaging the multimeter or causing misreading.

Failure rate and life of resistors

The failure rate and life of the resistor are affected by many factors, mainly including the working environment, the size of the current passed through, the heat dissipation conditions, the working voltage, and the manufacturing quality and material of the resistor itself. The following is a detailed description of the failure rate and life of the resistor:

-

Failure rate: In general, the failure rate of patch resistors is relatively low, but it does not mean that their life will be short. In fact, the failure rate of the resistor is relatively low compared to other electronic components. Under high pressure and high temperature working environment, the failure rate of the resistance will increase significantly, so the life and reliability of the resistance need to be specially considered in specific application scenarios.

-

Life: The service life of the resistor is usually long, it is generally believed that it can reach several decades, and some even more than 30 years. But it depends on the conditions in which they work.

Key factors include:

-

Working environment: A dry and ventilated environment helps to extend the life of the resistor, and a wet or polluted environment will accelerate the oxidation of the resistor and affect its performance.

-

Current and heat dissipation: The current through the resistor should not exceed its rating, too much current will cause the resistor to overheat, thereby shortening its life. Good heat dissipation design is essential to maintain long-term stable operation of resistors.

-

Temperature: Temperature is an important factor affecting the life of the resistor, usually for every 10°C increase in temperature, the life of the resistor may be reduced by half. Therefore, controlling the operating temperature is essential to ensure a long life.

-

Materials and Manufacturing quality: High quality materials and manufacturing processes can improve resistance durability, for example, high quality NTC thermistors are recommended in systems with an expected operating life of more than 20 years.

-

-

Consideration of specific types of resistors: Variable resistors, such as potentiometers, usually have a higher failure rate than fixed resistors due to mechanical wear and other factors. High resistance resistors and precision resistors are more sensitive to environment and temperature and may require more stringent conditions of use and storage.

Resistor purchase guide

First of all, it is clear whether the resistor will be used in the digital circuit or the analog circuit, because different types of circuits may have different requirements for the stability and accuracy of the resistance. Understand the role of the resistor in the circuit, such as whether it is used for current limiting, voltage division, filtering, or as a load. Calculate the required resistance value based on the circuit design. You can use color ring coding to identify resistance values for fixed resistors, or consult the data book for exact values. Consider the accuracy requirements, select the appropriate tolerance level of resistance, such as ±1%, ±5% or ±10%. Calculate the maximum power consumption of the resistor in the circuit and ensure that the rated power of the selected resistor can withstand without overheating. In general, the greater the power, the larger the volume of the resistance. Consider the temperature of the environment used, as high temperatures can reduce the power handling capacity of the resistor.

Select the right package, such as SMD (surface mount) or DIP (through hole insert), depending on the design space and assembly method of the board. Common SMD sizes are 0402, 0603, 0805, 1206, etc., according to the required space and welding difficulty to choose. Different resistance materials affect their performance and cost, such as carbon film resistors for general applications, metal film resistors provide better stability and accuracy, and metal oxide film resistors are used for higher precision and stability occasions. If the resistance will be used in harsh environments, such as high temperature, high humidity or chemical corrosion sites, you should choose a resistance with the appropriate level of protection.

Under the premise of meeting the performance requirements, compare the prices of different brands and suppliers, and consider the economy of bulk procurement. Be sure to select reputable suppliers that provide technical support. To consider the availability of resistance, choose a universal type or easy to find a replacement model, in case of emergency. Before large-scale application, the actual circuit test of the sample is carried out to verify whether its performance meets the design requirements.

How do I change the resistor

Replacing a resistor is a relatively straightforward process, but requires some basic knowledge of electronics and careful operation to avoid harm to the circuit or itself. The following are the general steps and precautions for replacing the resistor:

Preparatory work

-

Power off: Ensure that the device has been disconnected from the power supply. For circuits with large capacitors, discharge may be required.

-

Tools: Common tools include a screwdriver, tweezers, welding tools (such as electric soldering iron), tin absorbent, soldering wire, and multimeter.

-

Resistor information Confirmation: Use a multimeter to measure the actual resistance of the damaged resistor (if it can still be measured) and record its specifications (such as resistance, power, package form).

Replacement procedure

-

Remove the old resistor:

-

For through-hole resistors, use a soldering iron to heat and remove the solder at both ends, gently pulling out the resistors.

-

For SMD (surface mount) resistors, use the same soldering iron to heat the solder joints, but be more careful not to damage the PCB or adjacent components.

-

-

Clean the solder joint: Use a tin absorber or a tin absorber to remove residual solder and make the pad clean, clean with alcohol and cotton swabs if necessary.

-

Install a new resistor:

-

Verify that the specifications of the new resistor meet the requirements of the original resistor or circuit.

-

For through-hole resistors, apply a small amount of solder to the pad, then insert the resistance and secure it with a soldering iron.

-

For SMD resistors, gently place in the correct position and carefully weld both ends with a soldering iron, taking care not to allow the element to shift.

-

-

Check welding quality: Check whether there is cold welding, short circuit or virtual welding after welding to ensure that each solder joint is smooth and full.

-

Verify the resistance: Use the ohm stop of the multimeter to measure the resistance values at both ends of the new resistance again to confirm that it is correct and consistent with the circuit design.

-

Circuit test: If it is safe to reconnect the power supply, use a multimeter or circuit tester to check whether the function of the relevant circuit is normal.

Look out

-

During the whole process, avoid electrostatic damage to the sensitive components.

-

Ensure that the welding temperature is moderate, too high will damage the component or PCB, too low may lead to poor welding.

-

For special types of resistors (such as thermal, pressure, photosensitive, etc.), appropriate replacements must be selected according to their characteristics and circuit functions, and can not be replaced at will.

-

If you are not familiar with welding, it is recommended to seek professional help or operate under guidance to prevent damage to the equipment or cause safety accidents.

Use and adjustment skills of adjustable resistor

An adjustable resistor, also known as a potentiometer, is an electronic component that can manually adjust the resistance value and is widely used in various circuits to achieve dynamic adjustment of the resistance value. Here are some tips and precautions for using and adjusting adjustable resistors:

Preparation before use

-

Identification pins: Most adjustable resistors have three pins, two are fixed (fixed piece) and one is active (moving piece). Confirm the pin layout by reviewing the data book or circuit diagram.

-

Check specifications: Verify that the rated power, maximum operating voltage, resistance range, and adjustment characteristics (such as linear or logarithmic) of the adjustable resistor meet the requirements of the circuit.

-

Safety measures: Ensure installation and initial setup are performed without a power connection to avoid short circuits or damage.

Adjustment skill

-

Power off regulation: Although some cases can be adjusted while the circuit is working, it is recommended to perform initial regulation in the power off state to avoid instability of the current or voltage in the circuit.

-

Positioning adjustment: Use a flat-head screwdriver or a dedicated tool to gently screw in the adjustment port and turn it clockwise or counterclockwise as needed. Pay attention to adjust the strength to avoid damaging the internal structure.

-

Gradual adjustment: For occasions requiring fine adjustment, the method of gradual adjustment and test can be used to check whether the response of the circuit meets the expectations after each fine adjustment.

-

Observe feedback: If conditions permit, use a multimeter to monitor changes in voltage at both ends of the resistor or current through the circuit to help adjust more precisely to the desired resistance value.

-

Avoid limit position: Try not to adjust the moving piece to the full minimum or maximum resistance position, as this may affect the life or accuracy of the resistance.

Maintenance and precautions

-

Avoid over-rotation: Over-rotation may cause damage to the mechanical structure inside the adjustable resistor.

-

Environmental factors: Consider the impact of temperature and humidity on the resistance value, especially when precision regulation.

-

Regular inspection: After long-term use, resistance values may change due to wear and tear, and regular inspection and recalibration may be necessary.

-

Prevent static electricity: Before operating, especially when handling sensitive circuits, ensure that anti-static measures have been taken.

By following the above tips and precautions, adjustable resistors can be effectively used for circuit debugging and performance optimization.