Electrical protection: Principle and application of gas discharge tube arrester

2024-05-28 15:44:26 1176

Lightning arrester plays a vital role in modern electrical systems, and the gas discharge tube arrester stands out among many lightning protection solutions with its unique performance characteristics.

What is the working principle of gas discharge tube arrester

The core of a gas discharge tube arrester is the specific gas it is filled with, such as argon, neon, or a mixture of them. Under normal working conditions, these gases have high insulation, making both ends of the arrester present high impedance and almost non-conductive. However, when the external circuit encounters an overvoltage situation, the electric field strength in the gas increases sharply, reaching the breakdown voltage of the gas, causing the gas to ionize and rapidly change from an insulating state to a conductive state. This process can direct overvoltage energy to the ground, effectively protecting electrical equipment from damage.

What are the classification of gas discharge tube arrester

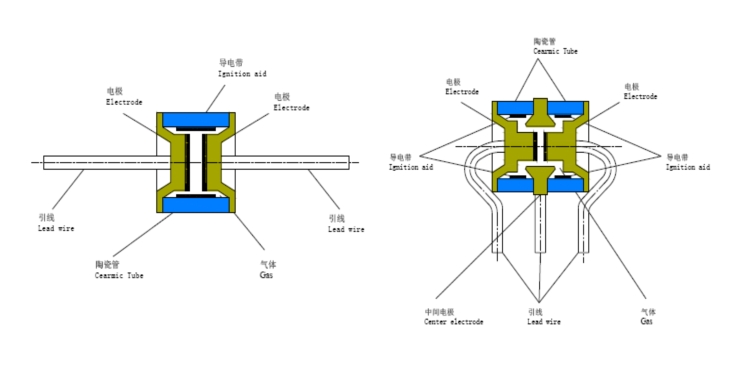

Gas discharge tube arrester is mainly divided into the following two categories:

-

Closed gas discharge tube arrester: This type of arrester is filled with a specific inert gas, such as argon, neon, etc. They use a sealed structure, can provide one-time large electrical discharge, suitable for lightning protection of communication systems. The closed design ensures stability and safety, avoiding the influence of the external environment on the internal gas.

-

Open discharge tube arrester: This type of arrester is actually an air discharger, and its working principle is based on the discharge phenomenon in the air. Compared with closed gas discharge tubes, they may have visible sparks at work, and the application situation may be relatively limited, but it is now less used.

In practical applications, the gas discharge tube arrester will be further subdivided according to different designs and uses, for example, some have a thermal protection device, when the operating temperature exceeds the safe range, it will start a short-circuit device to protect the device from damage. In addition, the gas discharge tube can also be combined with other components such as varistor to form a composite arrester to improve the flow capacity and reduce residual voltage to meet a wider range of protection needs.

What are the application range of gas discharge tube arrester

Because of its unique protection characteristics and working principle, gas discharge tube arrester has a wide range of applications in many fields, mainly including but not limited to the following aspects:

-

Communication system protection: This is one of the most typical applications of gas discharge tube arrester, which is widely used in telephone switches, network communication equipment, satellite communication systems, mobile base stations, etc., to protect these systems from overvoltage damage caused by lightning.

-

Power supply and signal line protection: In the power supply system, control panel, signal transmission line, the gas discharge tube arrester can effectively prevent the damage of lightning overvoltage and operating overvoltage to the equipment to ensure the stable operation of the system.

-

Radio and television systems: including medium wave broadcast transmitters, output line protection of TV transmitting stations, and the inlet end protection of related receiving equipment to reduce the impact of lightning on broadcast signal transmission.

-

Buildings and infrastructure: Used for lightning protection of tall structures such as roofs, smokestacks and signal towers, to protect the safety of electrical equipment and personnel in buildings.

-

Electronic equipment protection: including computer, server, monitoring system and other sensitive electronic equipment interface protection, to prevent lightning through the line intrusion caused by equipment damage.

-

Lighting and display technology: Although not the mainstream protection method used directly for lighting devices, gas discharge tubes can be used for overvoltage protection in some special lighting systems and display devices (such as early plasma displays).

-

Medical equipment: In some medical equipment, gas discharge tubes can be used as overvoltage protection components to ensure the safe operation of equipment under extreme conditions such as lightning.

The difference between gas discharge tube arresters and other types of arresters (such as metal oxide arresters)

The main difference between gas discharge tube arrester and metal oxide arrester (also known as zinc oxide arrester) is their working principle, response speed, residual voltage characteristics, and application scenarios:

In terms of working principle:

-

Gas discharge tube arrester: mainly relies on the ionizing discharge of the internal gas at high voltage to conduct the current. When the overvoltage reaches a certain value, the internal gas ionizes, forming a conductive channel and introducing the overvoltage into the ground wire. This type of arrester has a high breakdown voltage and a relatively slow reaction rate.

-

Metal oxide arrester: The core component is a metal oxide resistor with nonlinear voltammetry characteristics, such as zinc oxide (ZnO). Under normal operating voltage, its resistance is very high, almost no conduction; But when the voltage exceeds a certain threshold, the resistance drops rapidly, allowing large currents to pass through, thus protecting the back-end circuit. Metal oxide arrester has high response speed and low residual pressure.

Response speed:

-

The response time of the gas discharge tube arrester is relatively slow because it takes time for the gas to ionize and form a discharge path.

-

Metal oxide arresters respond very fast, almost instant action, can suppress overvoltage in a very short time, providing more effective protection for equipment.

Residual pressure characteristics:

-

The residual voltage of gas discharge tube arrester after conduction is high, which may not be friendly to some sensitive equipment.

-

Metal oxide arrester is more suitable for protection of voltage sensitive electronic equipment due to its excellent nonlinear characteristics and low residual voltage after conduction.

Application scenarios:

-

Because of its ability to withstand large surge current, gas discharge tube arrester is usually used in communication lines, power input terminals and other occasions that need to deal with large energy.

-

Because of its fast response and low residual voltage characteristics, metal oxide arresters are more suitable for precision electronic equipment, substations, distribution systems and other places that need fine protection.

Difference summary: Gas discharge tube arrester compared with metal oxide arrester, the main difference of gas discharge tube arrester is response speed and residual pressure. The initial response time of the gas discharge tube is longer, but it can withstand higher inrush current, which is suitable for protection of intermittent large current shock. The metal oxide arrester has fast reaction speed and low residual pressure, which is more suitable for overvoltage protection in continuous working state. In addition, metal oxide arresters are smaller and easier to maintain, but may be at risk of thermal collapse under extreme conditions.

Key points and precautions for the selection of gas discharge tube arrester

INFINITECH suggests that the following key factors should be considered when selecting:

-

The DC discharge voltage of the gas discharge tube should be higher than the maximum voltage during normal operation of the line to avoid affecting the normal operation of the line.

-

The pulse discharge voltage should be lower than the highest instantaneous voltage value that the line can withstand, to ensure that the gas discharge tube can respond quickly when the instantaneous overvoltage, and limit the overvoltage to a safe level in advance.

-

The holding voltage should be as high as possible, so that after the overvoltage disappears, the gas discharge tube can be quickly extinguished and the normal state of the line can be restored.

-

Given the slow response of the gas discharge tube, it is necessary to evaluate the response time requirements of the system and whether it needs to be used with other fast response elements, such as varistors.

-

Pay attention to the continuous flow characteristics and residual pressure of the gas discharge tube. High residual pressure may pose a threat to sensitive devices. Consider whether measures need to be taken to mitigate the continuous flow effect and reduce residual pressure.

-

Depending on the installation space, choose the appropriate size and structure of the gas discharge tube, such as 2-pole or 3-pole construction, the latter may have thermal protection to prevent overheating damage.

-

Make sure that the ground wire is short and thick enough to allow quick discharge of large transient currents. At the same time, follow the manufacturer's instructions during installation to ensure correct and firm installation.

-

The gas discharge tube is not suitable for direct differential mode protection on the power line, nor is it suitable for occasions where the signal frequency voltage is close to its breakdown voltage.

-

The selected gas discharge tube should withstand a current not lower than the maximum abnormal current that may occur on the line to ensure effective protection under extreme conditions.

-

Note that the starting voltage and residual voltage of different batches of products may be different, choose a reputable brand to ensure the consistency of product quality.

Installation and maintenance method of gas discharge tube arrester

Installation method:

-

Location selection: Determine the appropriate installation position, generally located at the front of the protected device, near the power supply or signal line entrance, to ensure that the lightning overvoltage can be effectively intercepted.

-

Check and test: Before installation, check whether the type and specifications of the arrester conform to the design requirements, and perform necessary electrical performance tests, such as DC reference voltage, discharge voltage, etc., to ensure that it is in good condition.

-

Installation direction: Confirm the installation direction of the arrester, especially for the polar gas discharge tube, to ensure correct installation.

-

Fixed and connected: Use the appropriate fixed parts to firmly install the arrester in the predetermined position, ensure that the cross-sectional area of the connection wire is sufficient, the connection is tight, and the contact is good, to avoid loosening due to vibration.

-

Grounding: Ensure that the grounding wire of the arrester is connected reliably, and the grounding resistance should meet the requirements, usually less than 10 ohms, to achieve effective discharge current.

-

Distance and isolation: Keep an appropriate distance from other devices to avoid affecting surrounding devices during discharge. At the same time, consider that the exhaust channel should be unobstructed and not pose a threat to other devices.

Maintenance method:

-

Regular inspection: Regularly check whether the appearance of the arrester has cracks, damage or corrosion signs, and whether the installation is firm, and whether the connection part is loose or oxidized.

-

Performance test: Perform electrical performance test according to the specified period, such as measuring leakage current, insulation resistance, etc., to determine whether the arrester can still work normally.

-

Record and replace: record the working status of the arrester, once the performance is found to decline or reach the expected life, it should be replaced in time. Usually, gas discharge tube arresters may need to be replaced after experiencing multiple discharges.

-

Cleaning and maintenance: Keep the arrester and the surrounding environment clean to avoid dust accumulation affecting heat dissipation and performance.

-

Pre-thunderstorm inspection: Before the thunderstorm season, inspection and testing should be strengthened to ensure that the arrester is in the best working condition.

-

Professional knowledge: During installation and maintenance, only professional personnel with appropriate electrical knowledge and skills should perform the installation and maintenance, and follow the safety operation rules to ensure personal safety.

Following the above installation and maintenance methods, you can ensure that the gas discharge tube arrester can effectively play a role, extend its service life, and ensure the safety of the protected equipment.

Life and fault judgment of gas discharge tube arrester

The life of gas discharge tube arrester is affected by many factors, generally up to several years to ten years. The fault can be determined by observing whether there are cracks and deformation on the outside, or using professional instruments to measure its insulation resistance and conduction characteristics. Once it is found that the arrester cannot be restored to the high resistance state after operation, or the insulation resistance decreases significantly, it indicates that it has failed and should be replaced in time.

Test standards and certification requirements for gas discharge tube arresters

Internationally, the test standards of gas discharge tube arrester mainly include IEC 61643 series and ANSI/UL 1449. These standards cover electrical performance, mechanical strength, environmental adaptability and safety of arresters. When purchasing, confirm whether the product has passed the corresponding national or regional safety certification, such as CE, UL, TUV, etc., is a key step to ensure product quality and safety.