PMIC basic functions, classification and selection guide

2024-05-09 15:52:27 133

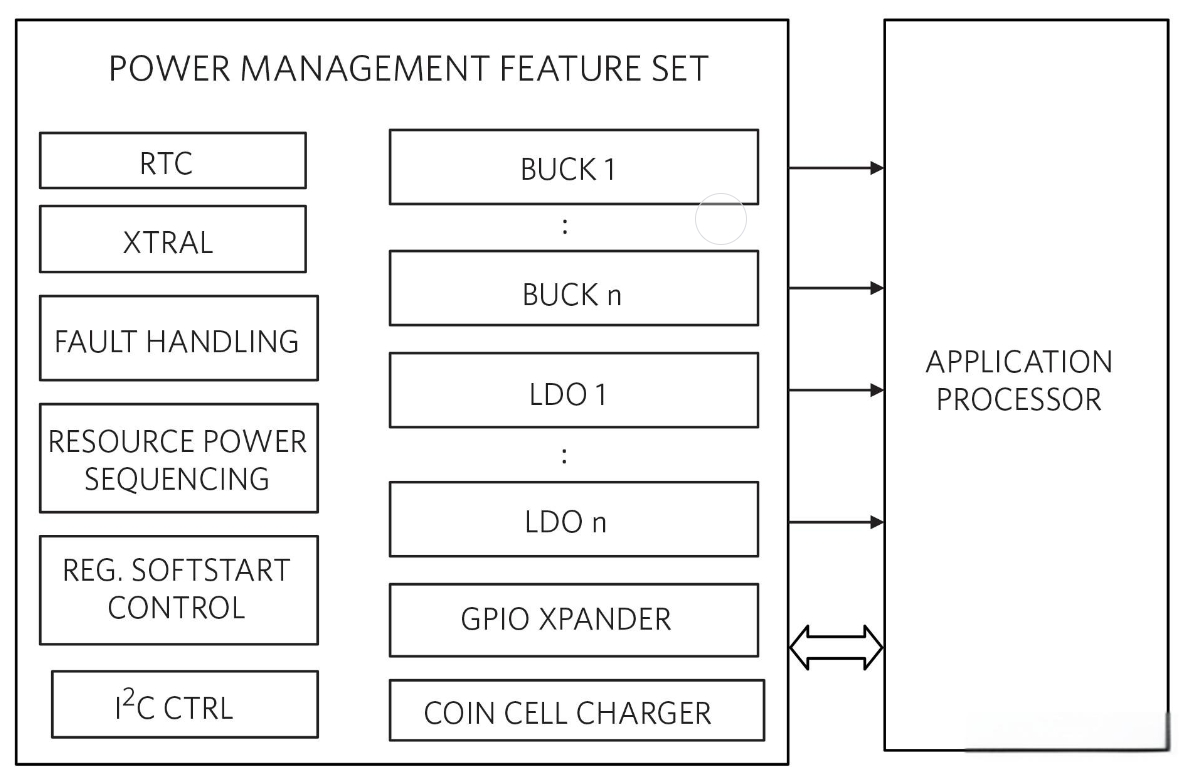

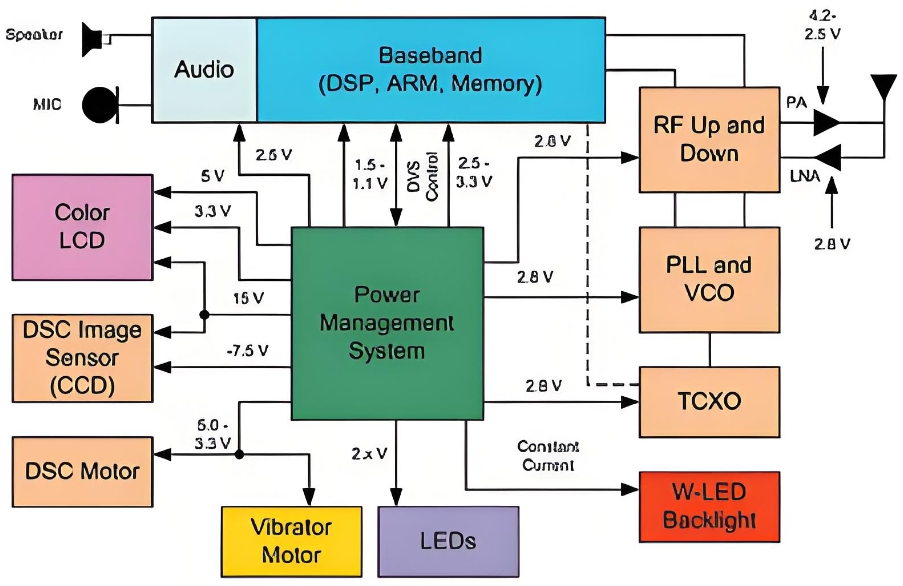

Power Management (PMIC) is a highly integrated circuit chip designed to efficiently manage and regulate the power supply in electronic devices. Its main functions include power conversion, distribution and monitoring and control of power status to meet the needs of different subsystems or components. The PMIC can receive input voltage from the battery or external power supply and convert it into various voltage and current levels required by the system through a series of complex circuits (such as DC-DC converters, low-voltage differential linear regulator LDO, battery charge controller, etc.) to ensure stable and efficient operation of each part.

Basic functions of PMIC

-

Power management: The PMIC is capable of receiving input power from batteries or AC adapters and distributing and adjusting the power supply according to the real-time needs of the system. This includes dynamically adjusting the power strategy in different operating modes (e.g., standby, sleep, high performance) to optimize energy efficiency.

-

Voltage regulation: With an integrated DC-DC converter and LDO (Low voltage Difference linear Regulator), the PMIC is able to convert the input voltage into a variety of output voltage levels required for different components within the system. These converters can be step-down, step-up, or buck-boost types to suit different voltage conversion requirements.

-

Current control: The PMIC is also responsible for controlling the current flow to the individual components to ensure that the maximum rated current of the components is not exceeded while meeting their operating requirements, especially in battery charging and high power consumption applications, where accurate current control is particularly important.

-

Provision of a variety of power rails: Modern electronic devices often require multiple power rails of different voltage and current levels to supply different parts of the processor, memory, sensors, etc. The PMIC is able to manage these power rails simultaneously, ensuring that each part receives a stable and appropriate power supply.

-

Battery management: In battery-powered devices, PMIC monitors battery status (including power, temperature, charging status, etc.) and implements intelligent charging algorithms, including fast charging technology, while providing protection functions such as overcharge, overdischarge, and short circuit to maintain battery health and extend service life.

-

Protection function: In order to improve the overall safety and reliability of the system, PMIC integrates over-voltage protection, over-current protection, over-temperature protection and other circuits, which can respond quickly in abnormal circumstances to avoid hardware damage.

The main categories of PMIC

Power management integrated circuits (PMIC) can be mainly divided into the following categories according to their functions and application fields:

-

Linear voltage regulator: This type of PMIC reduces and stabilizes the input voltage to the load by adjusting the resistance through the device. Their advantage is that the output voltage is very stable, low noise, suitable for noise-sensitive analog circuits and sensor power supply, but the efficiency is relatively low, especially in the case of large pressure differences.

-

Switching regulators: Switching regulators, such as Buck, Boost, buck-Boost, etc., adjust the output voltage through high frequency switching operation, which is more efficient and smaller than linear regulators, suitable for applications requiring high power output. Although they may produce more electromagnetic interference (EMI), modern designs often incorporate filtering and shielding technology to mitigate this problem.

-

Battery management chip: Focus on battery charge control, discharge protection, health status monitoring (such as remaining charge SOC, battery temperature) and battery balance functions. They ensure safe battery use, extend battery life, and provide an indication of charging status.

-

LED drivers: Designed for LED lighting and display applications, they can control the brightness and current of leds, usually with dimming, pulse width modulation (PWM) control, and overtemperature and overcurrent protection.

-

Charge controller: A PMIC specifically designed to manage the battery charging process, including the implementation of fast charging technology, and to ensure that the charging process is safe and efficient.

-

Voltage/current controller: Provides accurate voltage or current output for scenarios that require tight control of power supply, such as microprocessor core voltage regulation.

-

Power sequence controller: Ensure that when the system is powered on and off, the power rails are opened or closed in a predetermined sequence to prevent hardware damage.

-

Energy harvesting and energy Storage Management: In some low-power applications, the PMIC may contain energy harvesting modules capable of collecting energy from the environment (such as solar energy, vibration, etc.) and managing its storage and distribution.

PMIC design and selection principles

When designing and selecting a power management integrated circuit (PMIC), a series of principles should be followed to ensure that the selected PMIC can meet system requirements and improve overall performance and efficiency. Here are some key selection principles:

First of all, define the specific requirements of the system for power management, including the number of voltage rails required, voltage and current levels, dynamic voltage regulation capabilities, efficiency targets, power consumption limits, etc. Evaluate the integration of the PMIC, a highly integrated PMIC can reduce the number of external components, reduce PCB size, reduce design complexity and cost. However, it is necessary to weigh whether all the integrated functions are required by the system. Choose a PMIC with high conversion efficiency to reduce energy waste and heating, ensuring that the system can maintain good thermal performance under high loads. Consider the thermal design parameters (such as maximum junction temperature, thermal resistance) and heat dissipation scheme of the PMIC. If the system has specific power-on and power-off sequence requirements, select a PMIC with built-in timing control logic or programmable timing to ensure safe system startup and shutdown. For battery-powered devices, it is critical to choose a PMIC with advanced battery management features such as intelligent charging algorithms and battery protection.

In consideration of possible future system upgrades or adjustments, select a PMIC that supports software configuration and parameter adjustments for later optimization and adaptation to changes. Select the appropriate package form and size of PMIC according to the space limitations of the device, while considering the heat dissipation performance of the package. Consider price, performance, reliability and long-term maintenance costs to choose cost-effective solutions.

Choosing suppliers with good technical support, rich reference design and good market reputation can help shorten the development cycle and reduce risks. Ensure that the selected PMIC complies with relevant industry standards and specifications (e.g. AEC-Q100 for automotive electronics, safety certification, etc.), as well as market specific regulatory requirements.

The charging principle of lithium battery and the role of PMIC in it

Lithium battery charging principle

When the battery voltage is below a certain threshold, a small current is used to charge the battery to prevent the precipitation of lithium metal, which is mainly to activate the battery and gradually increase the battery voltage to a safe level. Once the battery voltage reaches a preset safe level (usually about 3.0V to 4.2V per unit), the charger enters the constant current phase, charging the battery at a relatively constant current, and the battery voltage gradually rises. When the battery voltage reaches the set maximum voltage (such as 4.2V per unit), the charger turns to constant voltage charging mode, and the current begins to gradually decrease until the charging is nearly complete, at which time the battery is close to full capacity. When the current drops to a low level (such as 0.05C, that is, 5% of the battery capacity), it indicates that the battery is almost full and the charge is over. Some chargers will also combine temperature monitoring, voltage slope judgment and other advanced algorithms to determine the charging termination point.

The role of PMIC in lithium battery charging

-

Voltage and current control: PMIC ensures that the lithium battery is charged according to a safe and efficient charging curve by precisely controlling the charging voltage and current, preventing overcharging and overheating.

-

Charging status monitoring: PMIC continuously monitors the voltage, current and temperature of the battery, and adjusts the charging parameters if necessary to adapt to changes in the battery status to ensure the safety of the charging process.

-

Charging algorithm implementation: PMIC integrates advanced charging algorithms, such as constant current constant voltage (CC/CV) algorithm, as well as more complex battery management algorithms, such as temperature compensation, charging rate adjustment, etc., to optimize charging efficiency and battery life.

-

Battery protection: PMIC provides safety functions such as overcharge protection, overdischarge protection, short circuit protection and temperature protection to prevent battery damage under abnormal conditions.

-

Energy management: In multi-cell or complex systems, PMIC can also manage balanced charging between battery packs to ensure that all battery cells are in a consistent state of charge, extending the life of the entire battery pack.

Application example of PMIC in smart phone

The realization of fast charging technology

With advanced PMIC, smartphones can support a variety of fast charging protocols, such as QC, PD, etc., significantly reducing charging time and improving user experience.

Fine battery management

PMIC's integrated battery management system can accurately monitor battery power and health status, optimize charging strategies, and extend battery life.

Multi-power rail efficient control

In an environment where energy-intensive components such as multi-core processors and high-definition displays coexist, the PMIC ensures that each part gets the most appropriate power supply by precisely controlling multiple power rails.

Application of PMIC in automotive electronics

Power supply for ADAS system

For advanced driver assistance systems (ADAS), PMIC provides a stable and reliable power supply to ensure uninterrupted operation of sensors and processing units such as radar and cameras.

Energy optimization for infotainment systems

In the vehicle's infotainment system, PMIC balances the power demand for multimedia playback, navigation and other functions through intelligent power distribution, while considering the vehicle start-stop state to optimize energy consumption.

Fault diagnosis and resolution of power management IC

Troubleshooting steps:

Symptom observation: First identify specific problems with the device, such as failure to turn on, rapid battery depletion, erratic performance, or overheating, which may be related to the power management IC.

Voltage measurement: Use a multimeter or oscilloscope to measure the input and output voltages of the power management IC to ensure they meet the device specifications. Abnormal voltage readings may indicate a problem with the power management IC.

Peripheral component inspection: Check the capacitors, inductors, resistors and other components around the power management IC to see if there is damage, short circuit or open circuit, because these will also affect the normal operation of the power IC.

Temperature monitoring: Assess the heat dissipation of the device, check the power management IC and its vicinity for abnormal heat, high temperature may be an important factor in the failure.

Electrostatic investigation: Consider whether electrostatic discharge is a possible cause of damage, especially in the maintenance process need to pay attention to electrostatic protection measures.

Professional diagnostic tools: The use of specialized circuit diagnostic tools or software to assist judgment, some complex problems may require more professional instruments to locate.

The solution:

Restart the device: If the problem is caused by a temporary overload or software conflict, try restarting the device to resolve the problem.

Cleaning and cooling: If a heat dissipation problem is found, clean the heat dissipation channel and ensure that the equipment has good ventilation conditions.

Replace damaged components: If it is confirmed that the power management IC or its peripheral components are damaged, the corresponding parts need to be replaced. Make sure the new part matches the model and specification of the original.

Re-weld: For power management ics welded to the circuit board, check whether the solder joints are intact and re-weld if necessary.

Whole machine inspection: If the power problem occurs frequently, it may be that the entire power system or the motherboard has a deeper problem, then a more comprehensive inspection may be needed or a replacement of the whole machine may be considered.

Professional maintenance: For complex faults, it is recommended to be handled by professional maintenance personnel to avoid more serious damage caused by their own operation.

Please note that before performing any repairs, ensure that the power is turned off and appropriate electrostatic protection measures are taken to avoid further damage.